ZJ40 Skid-Mounted Drilling Rigs

This series of skid-mounted drilling rigs include three models that are respectively ZJ40/2250J, ZJ40/2250LDB and ZJ40/2250L. They are suitable for being applied in drilling engineering to drill wells with the depth lower than 4000m. They can be used in different environments such as shallow sea areas, beaches, desert and cold areas based on the need of customers.

ZJ40/2250J Skid-Mounted Drilling Rig

Features

1. Mechanical transmission is adopted in the main components of our ZJ40/2250J skid-mounted drilling rig. This drilling equipment is highly cost-effective since it is convenient to operate and maintain.

2. Powered by three sets of diesel engines with compound belt transmission system, our drilling machine has low operation cost and is friendly to the environment.

3. With low position installed drawworks, this machine is easy to be moved.

4. Equipped with a hydraulic disk brake whose torque is large, the drawworks is safe and reliable.

Technical Parameters

| Nominal drilling depth | 4000m (drill rod:114mm) | |

| 3200m (drill rod:127mm) | ||

| Maximum hook load | 2250kN | |

| Rope system of travelling system | 5×6; Successively twined | |

| Rated power of drawworks | 735kW (1000hp) | |

| Gear number of drawworks | 4 forward | 6 forward 2 reverse |

| Diameter of drilling wire rope | Φ32mm | |

| Opening diameter of rotary table | 698.5mm (27 1/2") | |

| Gear number of rotary table | 4 forward 2 reverse | 6 forward 2 reverse |

| Drilling pump quantity and power | 2×1300hp | |

| Substructure | Block type | Box-on-box type |

| Substructure height and clearance height under rotary table beam | 7.5m; 6.3m | 6m; 4.8m |

| Derrick shape and effective height | K-shape; 43m | |

| Transmission mode | Hydraulic transmission compound belt transmission | |

| Main generator set quantity and power | 3×810kW | |

| Auxiliary generator set quantity and power | 2×400kW | |

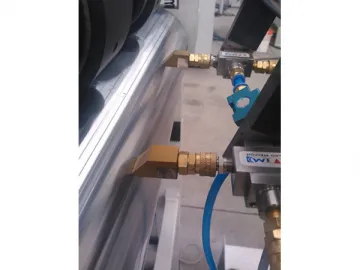

| High pressure mud manifold | Φ103mm (drift diameter)×35MPa | |

| Effective volume of solid control system | 260m3 | |

ZJ40/2250LDB Skid-Mounted Drilling Rig

Features

1. The rotary table and drawwarks are driven separately. The rotary speed and torch of the rotary table and the mud pump can be regulated respectively according to the requirement of drilling technologies. These advantages make automatic drilling possible.

2. The rotary table and automatic drilling device of this boring machine adopt AC variable frequency full-digital automatic control technology. Thus this ZJ40/2250LDB skid-mounted drilling rig has the function similar to numerically controlled variable frequency electric drilling machine. Compared with the electric drilling machine, our product has lower running cost.

3. Our drilling machine is equipped with a touch screen which can be used to display, save and adjust the drilling parameters. The touch screen also makes remote management possible. With the touch screen, the driller make the drilling rig work in optimal state through adjusting the drilling parameters. It helps reduce the labor intensity and increase working efficiency of the driller.

Technical Parameters

| Nominal drilling depth | 4000m (drill rod:114mm) | |

| 3200m (drill rod:127mm) | ||

| Maximum hook load | 2250kN | |

| Rope system of traveling system | 5×6; Successively twined | |

| Rated power of drawworks | 735kW (1000hp) | |

| Gear number of drawworks | 4 forward | 4 forward 2 reverse |

| Diameter of drilling wire rope | Φ32mm | |

| Opening diameter of rotary table | 698.5mm (27 1/2") | |

| Gear number of rotary table | Stepless speed regulation | Double gears stepless speed regulation |

| Drilling pump quantity and power | 2×1300hp | |

| Substructure | Block type | |

| Substructure height and clearance height under rotary table beam | 7.5m; 6.3m | |

| Derrick shape and effective height | K-shape; 43m | |

| Transmission mode | Hydraulic transmission and compound chain transmission; AC-VFD-AC | |

| Main diesel engine quantity and power | 3×810kW | |

| Auxiliary generator set quantity and power | 3×400kW | |

| Variable frequency generator quantity and power | 1×600kW 1×45kW | |

| High pressure mud manifold | Φ102mm (drift diameter)×35MPa | |

| Effective volume of solid control system | 260m3 | |

ZJ40/2250L Skid-Mounted Drilling Rig

Features

1. Made of H-sectional steel, the derrick of our skid-mounted drilling rig is designed in a “K” shape. The derrick has open working visual field and is easy to be moved.

2. Block type substructure allows the drawworks and the derrick to be mounted in a low position. The derrick can be lifted with the power provided by the drawworks.

3. The drawworks is equipped with a sealed chain transmission system. The transmission system is composed of 4 forward gears and 2 reverse gears (or 6 forward gears with 2 reverse gears). Auxiliary driving device is also available for lifting the derrick in emergent situations.

4. Most of the operations can be done in the integrated driller control cabin.

5. The transmission system connected by universal shafts is easy to assemble and disassemble.

6. Designed with a seasonable block structure, the skid-mounted drilling rig can be hoisted integrally or transported by train or automobile in block.

7. This drilling machine is highly mechanized and can work in various environments.

Technical Parameters

| Nominal drilling depth | 2500-4000m (drill rod:114mm) |

| 2000-3200m (drill rod:127mm) | |

| Maximum hook load | 2250kN |

| Rope system of travelling system | 5×6; Successively twined |

| Rated power of drawworks | 1000kW |

| Gear number of drawworks | Single gear stepless speed regulation |

| Diameter of drilling wire rope | Φ32mm |

| Opening diameter of rotary table | 698.5mm (27 1/2") |

| Gear number of rotary table | Stepless speed regulation |

| Drilling pump quantity and power | 2×1300hp |

| Substructure | Slingshot type |

| Substructure height and clearance height under rotary table beam | 7.5m, 6.26m |

| Derrick shape and effective height | K-shape, 43m |

| Transmission mode | AC-VFD-AC ; One-for-one |

| Main generator set quantity and power | 3×1200kW |

| Auxiliary generator set quantity and power | 1×292kW |

| AC generator quantity and power | 3×1000kW 1×45kW 1×600kW |

| High pressure manifold for mud | Φ103mm (drift diameter)×35MPa |

| Effective volume of solid control system | 260m3 |

Links:https://www.globefindpro.com/products/44543.html

-

Lead-acid Battery Recycling Plant

Lead-acid Battery Recycling Plant

-

Flat & Satchel Paper Bag Machine

Flat & Satchel Paper Bag Machine

-

Magnetic Separator

Magnetic Separator

-

Plastic Pipe Shredder

Plastic Pipe Shredder

-

Vibrating Screen

Vibrating Screen

-

Envelope Making Machine (Pocket Envelope, model POCKET120)

Envelope Making Machine (Pocket Envelope, model POCKET120)

-

Aluminium Recycling Plant (Recycling Aluminum from Aluminum Composite Panels)

Aluminium Recycling Plant (Recycling Aluminum from Aluminum Composite Panels)

-

Plastic Film Recycling Line

Plastic Film Recycling Line

-

RL3NB Series Triplex Mud Pump

RL3NB Series Triplex Mud Pump

-

Heavy Duty Granulator

Heavy Duty Granulator

-

Double Shaft Shredder

Double Shaft Shredder

-

RL-CZ40 Truck-Mounted Drilling Rigs

RL-CZ40 Truck-Mounted Drilling Rigs