Pulp Dewater Machine

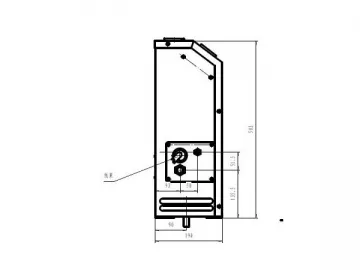

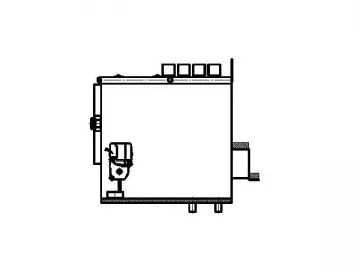

The HPM-1600 pulp dewater machine, also known as pulp dewatering machine, is mainly applied to compress paper pulp and reduce moisture content to meet the paper manufacture requirement of being less than 40%.

This pulp drying machine comes in horizontal design and button control mode, offering simple and safe operation. The whole chamber, grapple and ejecting gate are all made up of stainless steel, so this pulp dewater machine offers stout structure and superior corruption resistance. Furthermore, belt conveyor can be added to this pulp dewatering machine to facilitate feeding.

Advantages of Pulp Dewatering Machine

1. Feeding chamber

Featuring outstanding resistance against abrasion and corruption, the feeding chamber of this pulp machine can work with belt conveyor to ensure fast and clean feeding.

2. Water outlet

Water outlet of this pulp dewatering machine also adopts stainless steel. Rigid structure is designed for fast water discharge and pulp protection.

3. Ejecting gate

The square ejecting gate makes the pulp dewater machine highly practical for keeping bales clean.

Specifications of Pulp Dewatering Machine

| No. | Content | ||||||

| 1 | Compression chamber size (L × W × H) | 5400 × 1000 × 800mm | |||||

| 2 | Feeding gate size (L × W) | 1800 × 1000mm | |||||

| 3 | Bale size (W × H) | 1000 × 800mm | |||||

| 4 | Bale dimension (L × W × H) | 1100 × 760 × (up to 1400) mm | |||||

| 5 | Moisture content reduction | >=60% | |||||

| 6 | Total power | 37kW | |||||

| 7 | Power supply | 380V/3PH, 50Hz or customizable | |||||

| 8 | System pressure | 21.5MPa | |||||

| 9 | Control mode | Button control | |||||

| 10 | Belt conveyor dimension | Width | 2200mm | ||||

| Length | 10150mm | ||||||

| Speed | 2760m/min | ||||||

| 11 | Main motor | Model | Y250M-6 | Quantity | 1 | ||

| Nominal speed | 980rpm | Power | 37kW/50HP | ||||

| 12 | Hydraulic pump | Model | 250YCY14-1B | Quantity | 1 | ||

| Nominal output volume | 250ml/r | Nominal pressure | 31.5MPa | ||||

Comparison

After being processed by our pulp dewatering machine, moisture content can be decreased by over 60%. Clean bales are offered.

Comparison

1. Raw pulp with high moisture content

2. Bale with low moisture content

Links:https://www.globefindpro.com/products/44587.html

-

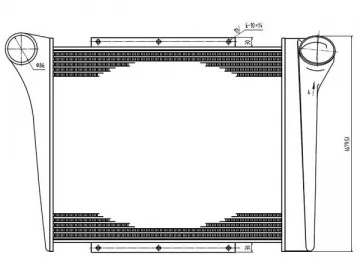

Intercooler

Intercooler

-

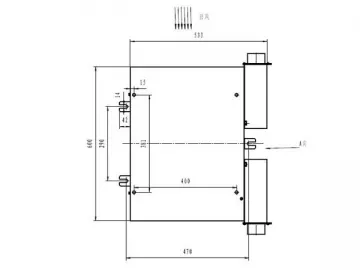

Heater Core

Heater Core

-

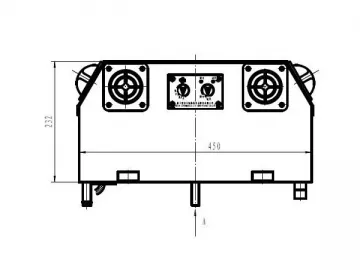

Air Conditioner for Loader

Air Conditioner for Loader

-

SBH150 Automatic Block Bottom Paper Bag Machine

SBH150 Automatic Block Bottom Paper Bag Machine

-

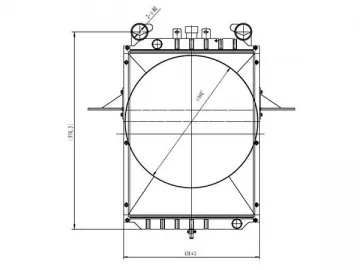

Engine Cooling System

Engine Cooling System

-

Air Conditioner for Road Roller

Air Conditioner for Road Roller

-

Hydraulic Dye Cutting Press (ModelMQ550)

Hydraulic Dye Cutting Press (ModelMQ550)

-

Air Conditioner for Grader

Air Conditioner for Grader

-

A/C Evaporator Core and Condenser Core

A/C Evaporator Core and Condenser Core

-

Air Conditioner for Bulldozer

Air Conditioner for Bulldozer

-

Air Conditioning Condenser

Air Conditioning Condenser

-

Shear Baler

Shear Baler