Melamine Polyphosphate (MPP)

Uses

1. Melamine Polyphosphate is often abbreviated as MPP. It is mostly applicable to PBT and polyamides, especially PA6, PA66, glass fiber reinforced PA6, PA66 and more.

2. The flame retardant nylon mixed with our product can be applied in a variety of injection and extrusion molding processes. It can satisfy all kinds of processing demands of glass-fiber reinforced polyamides.

Characteristics

1. Melamine Polyphosphate is a kind of eco-friendly flameproof material with low toxicity and no halogen. It conforms to European Environmental Protection requirements.

2. Due to superb processability, this fireproofing additive does not require any special screws combination or special glass fiber.

3. Different from general halogenated flame retardants, MPP can protect both equipment and mould from corrosion.

4. Our product features outstanding thermal stability and decomposition temperature of at least 330℃, so it is extremely suitable for glass fiber reinforced nylon.

5. MPP is white in color, thereby being conducive to the preparation of various colors.

Storage and Transportation

Melamine Polyphosphate should be handled with care. It must be sealed in prevention of moisture during storage.

Brief Description

| Synonyms | FR-NP; MPP |

| Chemical Formula | (C3H8N6)n(HPO3)m |

| CAS No. | 218768-84-4 |

| Appearance | White solid powder |

| Packaging | 20kg woven bag |

| Production Capacity | 1000mt/year |

Quality Standard

| Phosphorus | % | 15.0±1.0 |

| Moisture | % | ≤0.2 |

| Decomposition Temperature | % | ≥330 |

| Particle Size | μm | ≤25 |

| Density | g/cm3 | Approximately 1.6 |

| Bulk Density | g/cm3 | Approximately 0.5 |

Application of FR-NP in Nylon

1. Formula (Weight Ratio)

| PA66 | 49 |

| Glass Fiber | 25 |

| FR-NP | 25 |

| Additives | 1 |

2. Double Screw Processing Temperature in All Areas

| Area 1 (Feeding) | Area 2 | Area 3 | Area 4 | Area 5 | Area 6 | Area 7 | Area 8 (Vacuum) | Area 9 (Die Orifice) |

| 250 | 260 | 260 | 260 | 260 | 260 | 260 | 265 | 265 |

3. Performance Comparison between FR-NP Flame-retardant Glass Fiber Reinforced PA66 and Brominated Flame Retardant Glass Fiber Reinforced PA66 (Addition of 25% Glass Fiber)

| Properties | Br/Sb System | MPP | |

| Tensile Strength (MPa) | 145 | 150 | |

| Elongation at Break (%) | 2.5 | 2.5 | |

| Bending Strength (MPa) | 155 | 160 | |

| Flexural Modulus (GPa) | 10 | 12 | |

| Notched Impact Strength (KJ/m2) | 7 | 7 | |

| Vertical Combustion Performance UL94 | 1.6mm | V0 | V0 |

| 0.8mm | V0 | V0 | |

| 0.4mm | NT | NT | |

Links:https://www.globefindpro.com/products/44775.html

-

LKYS Flexo Printer Slotter

LKYS Flexo Printer Slotter

-

Sodium Bromite

Sodium Bromite

-

Resorcinol Bis(Diphenyl Phosphate) (RDP)

Resorcinol Bis(Diphenyl Phosphate) (RDP)

-

SJL Rotary Slotter

SJL Rotary Slotter

-

KL9 Flexo Case Maker

KL9 Flexo Case Maker

-

Diacetone Acrylamide (DAAM)

Diacetone Acrylamide (DAAM)

-

Melamine Cyanurate (MCA)

Melamine Cyanurate (MCA)

-

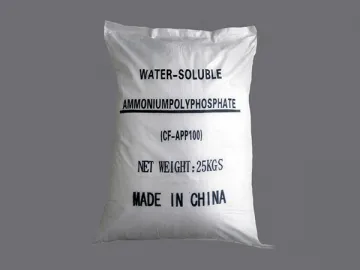

Ammonium Polyphosphate (APP)

Ammonium Polyphosphate (APP)

-

Triphenyl Phosphate (TPP)

Triphenyl Phosphate (TPP)

-

Lithium Bromide

Lithium Bromide

-

K6/K7 Flexo Printer Slotter with Vacuum Transfer

K6/K7 Flexo Printer Slotter with Vacuum Transfer

-

Lockable Gas Traction Spring

Lockable Gas Traction Spring