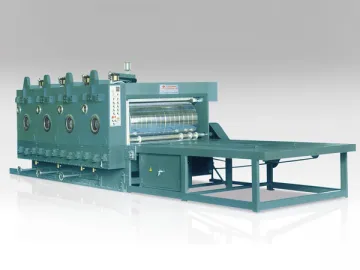

K2 Automatic Flexo Printer Slotter

K2

K2 automatic flexo printer slotter has spray lubrication system which drastically reduces noise while maximizes service life. This corrugated case maker also adopts motorized and manual control, as well as kick bar feed. As a result, this boxing machine is suitable for volume production of mid to low-end carton in mid to small size.

All electrical, electronic and pneumatic components are all highly in tune with European standards. These devices are endowed with outstanding reliability and safety, thus our automatic flexo printer slotter delivers easy operation and dependable performance.

Alternative option

K3 packaging equipment mainly uses lead edge feed.

Specification

| Data & Model | 1200×2000 | 1200×2400 | 1400×2400 | 1600×2800 | |

| Max. machine speed (sheets/min) | 200 | 200 | 200 | 180 | |

| Max. feeding size (mm) | 1180 × 2000 | 1180 × 2400 | 1380 × 2400 | 1600 × 2800 | |

| Min. feeding size (mm) | 320 × 750 | 320 × 750 | 360 × 750 | 420 × 750 | |

| Min. panel size | Slotting type R. (mm) | 160 × 160 × 160 × 160 | 160 × 160 × 160 × 160 | 160 × 160 × 160 × 160 | 165 × 165 × 165 × 165 |

| Slotting type L. (mm) | 250 × 90 × 280 × 90 | 260 × 90 × 260 × 90 | 280 × 90 × 280 × 90 | 250 × 90 × 250 × 90 | |

| Max. slotting depth (mm) | 320 | 320 | 350 | 560 | |

| Max. board thickness (mm) | 12 | 12 | 12 | 12 | |

| Max. printing area (mm) | 1150 × 2000 | 1150 × 2400 | 1320 × 2400 | 1540 × 2800 | |

| Printing plate thickness (mm) | 7.2 | 7.2 | 7.2 | 7.2 | |

Scan QR to Read

Links:https://www.globefindpro.com/products/44789.html

Links:https://www.globefindpro.com/products/44789.html

Recommended Products

-

Longway Printer

Longway Printer

-

Tris(1-Chloro-2-Propyl) Phosphate (TCPP)

Tris(1-Chloro-2-Propyl) Phosphate (TCPP)

-

Sodium Bromide

Sodium Bromide

-

Semi-automatic Gluer

Semi-automatic Gluer

-

Brominated Polystyrene (BPS)

Brominated Polystyrene (BPS)

-

XC-110G 3 Way Upright Fridge Freezer

XC-110G 3 Way Upright Fridge Freezer

-

Bis(2,3-Dibromopropyl Ether) of TBBA (BDDP)

Bis(2,3-Dibromopropyl Ether) of TBBA (BDDP)

-

Tris(Tribromophenyl) Triazine (FR-245)

Tris(Tribromophenyl) Triazine (FR-245)

-

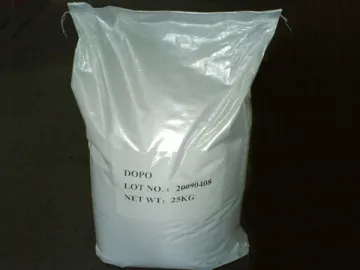

Dihydro-Oxa-Phosphaphenantrene-Oxide (DOPO)

Dihydro-Oxa-Phosphaphenantrene-Oxide (DOPO)

-

K8 Fixed Structure Flexo Printer Slotter

K8 Fixed Structure Flexo Printer Slotter

-

2-Carboxyethyl(Phenyl) Phosphinic Acid (CEPPA)

2-Carboxyethyl(Phenyl) Phosphinic Acid (CEPPA)

-

Diacetone Acrylamide (DAAM)

Diacetone Acrylamide (DAAM)