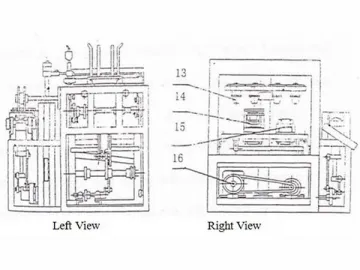

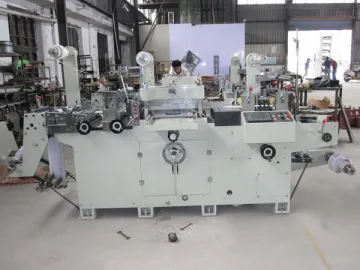

Single PE Coated Paper Cup Forming Machine

Introduction

The single PE coated paper cup forming machine is an automatic multi-station device. It enables automatic paper feeding, sealing (cup wall bonding), oiling, bottom blanking, heating, knurling, edge folding, photoelectric detecting, fault alarm, counting, variable frequency speed regulation, etc. Undoubtedly, it is the optimal equipment to produce paper cups of tea, coffee, ice cream and other beverages.

We can design moulds according to your requirements. The specifications of this paper cup forming machine vary via mould changing. Other paper cup machines like printing press, creasing machine and die cutting machine are also available.

Key Characteristics

1. Our single PE coated paper cup forming machine adopts cam indexing mechanism, which means that cam rotation is driven by indexing box. Meanwhile, all components of this device are manufactured in compliance with relevant standards, characterized by excellent universality and interchangeability, easy for maintenance.

2. Detecting system functions if there is no paper cup tube at heat-sealing and cup tube forming section, and in the meantime, the single-side PE coated paper cup forming machine will stop. Hence, this machine boasts of high automation.

3. Bottom blanking section is configured with mechanical probe-type detector to ensure detection accuracy and qualification rate of finished products.

4. Due to special emergency stop apparatus, the single PE coated paper cup forming machine stops and stays at the possibly highest position so that mould and heating furnace are completely detached, and paper cup burning is eradicated.

5. Thanks to storage tank, the vertical shaft of this equipment is well lubricated and can run for a long time without damage.

Main Technical Parameters

| Model | FG-PF12 |

| Paper cup specification | 3-12oz, other specifications are also available. |

| Paper material | 150-400g/m2, single side PE coated paper |

| Speed | 48-60 cups/min. |

| Power supply | 220V, 50Hz/380V, 50Hz |

| Total power | 4KW |

| Net weight | 1500kg |

| Gross weight | 2000kg |

| Overall dimension | 2600 (L)×14000 (W)×1700 (H) (mm) |

Configuration

Forming Process

1. The printed paper fan (unfolded shape of paper cup) is automatically processed into paper cup.

2. Then, cup wall is heated and sealed.

3. We adopt roll paper to make cup bottom. Our single PE coated paper cup forming machine performs automatic paper feeding and blanking.

4. Cup tube and bottom sealing is completed by using heat blower.

5. At knurling section, the cup bottom will be knurled.

6. We can get a perfect paper cup after final edge folding.

Samples

Links:https://www.globefindpro.com/products/44865.html

-

Slitter Rewinder

Slitter Rewinder

-

Double PE Coated Paper Cup Forming Machine

Double PE Coated Paper Cup Forming Machine

-

Flatbed Die Cutting Machine

Flatbed Die Cutting Machine

-

DC-220 Upright Fridge and Freezer

DC-220 Upright Fridge and Freezer

-

Flexographic Printing Machine with Three Die Cutting Stations

Flexographic Printing Machine with Three Die Cutting Stations

-

Printed Paper Cup Fan

Printed Paper Cup Fan

-

XC-70GF 3 Way Camping Freezer

XC-70GF 3 Way Camping Freezer

-

XC-35G 3 Way Camping Cooler

XC-35G 3 Way Camping Cooler

-

DC-32F Portable Freezer

DC-32F Portable Freezer

-

XC-100GAS Gas Fridge and Freezer

XC-100GAS Gas Fridge and Freezer

-

SC-15C Thermoelectric Cooler

SC-15C Thermoelectric Cooler

-

SC-10C Thermoelectric Cooler

SC-10C Thermoelectric Cooler