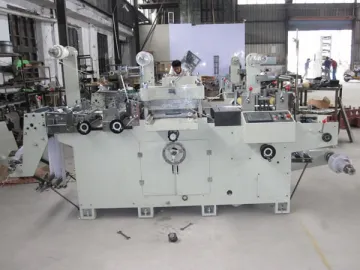

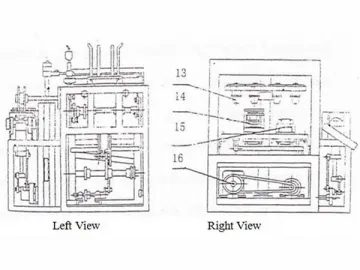

Flatbed Die Cutting Machine

Characteristics

1. The flatbed die cutting machine makes cost effective production a reality. It comes with tabulate structure and plate bed. Replacement of die-cutting plate is easy and cost-saving.

2. Its working speed reaches 20-180 times per minute, with die cutting area reaching 300×350mm. By adopting bottom-up operation mode and 4-axis linkage system, working pressure is more stable and

uniform.

3. Automatic oiling after starting up is available for drive part, for our flat bed die cutting press is configured with automatic oil circulation pump.

4. Flatbed precision die cutting, material towing and slitting are computer controlled.

5. Three photoelectric detectors are used by this flatbed die cutting machine to ensure precise positioning of printed label edge and length.

6. One-time operation containing die cutting, slitting, winding and unwinding can be achieved.

7. This flat bed die cutter is the ideal corollary equipment for flexographic printing press and gravure printing press, suitable for label printing factories.

Optional Configurations

1. Hot stamping device

2. Punching device

3. Film laminating device

Technical Parameters

| Model | FG-RD320Y |

| Die cutting speed | 20-180times/min. |

| Maximum roll width | 320mm |

| Maximum die cutting width | 300mm |

| Maximum die cutting length | 350mm |

| Maximum winding diameter | 450mm |

| Positional accuracy | ±0.1mm |

| Total power | 3KW |

| Power voltage | 220V±10% |

| Weight | About 2300kg |

| Overall dimension | 3050×1200×1450mm |

Samples

Links:https://www.globefindpro.com/products/44868.html

-

DC-220 Upright Fridge and Freezer

DC-220 Upright Fridge and Freezer

-

Flexographic Printing Machine with Three Die Cutting Stations

Flexographic Printing Machine with Three Die Cutting Stations

-

Printed Paper Cup Fan

Printed Paper Cup Fan

-

DC-35P Portable Freezer

DC-35P Portable Freezer

-

Creasing and Cutting Machine

Creasing and Cutting Machine

-

Intermittent Rotary Die Cutting Machine

Intermittent Rotary Die Cutting Machine

-

Double PE Coated Paper Cup Forming Machine

Double PE Coated Paper Cup Forming Machine

-

Slitter Rewinder

Slitter Rewinder

-

Single PE Coated Paper Cup Forming Machine

Single PE Coated Paper Cup Forming Machine

-

XC-70GF 3 Way Camping Freezer

XC-70GF 3 Way Camping Freezer

-

XC-35G 3 Way Camping Cooler

XC-35G 3 Way Camping Cooler

-

DC-32F Portable Freezer

DC-32F Portable Freezer