Rotogravure Printing Machine

Introduction

The rotogravure printing machine is developed by virtue of in-house design capability. It comes with man-machine interface and touch screen introduced from Taiwan, making operation much easier. By adopting external heating mode, printing speed can maximally reach 120m/min. Thus, this rotogravure printing press is ideal for mass printing. Generally, it suits BOPP, PET, CPP, PCVD and composite films and paper.

We also provide gravure printing press with 5 or 7 motors. The maximum printing speed of that with 7 motors reaches up to 130m/min. If you are interested in our machines, please send enquiry to us.

Key Configurations

1. Main drive mechanism

Frequency converter of Yaskawa is applied to this rotogravure printing machine for motor control to drive each set of printing plate, which is power saving and fast for registration.

2. Shaft-free imposition mechanism

Air cylinder is used for printing plate imposition to drive mandrel. Transverse adjustment can be achieved by means of screw movement. Thanks to this imposition device, plate replacing time is largely reduced. Meanwhile, plate concentricity is well ensured and printing effect is improved.

3. Doctor blade

The doctor blade of our rotogravure printing machine is vertically and angularly adjustable, driven by dual air cylinders. Transverse shift can be realized via cam movement driven by motor. By adopting this doctor blade, the service life of printing plate is greatly extended.

4. Impression lifting mechanism

We make use of dual impression cylinders for pressure increasing and adopt magnetic valve for electric potential self-lock to protect against cylinder leakage and coming off. This mechanism well ensures pressure uniformity and effectively eradicates chromatic aberration.

5. Manipulator for color register

Our rotogravure printer utilizes computer for controlling synchronous motor. Meanwhile, the manipulator in decelerated motion is used for ball screw adjustment, thus realizing automatic precision color register.

6. Winding and unwinding mechanism

The rotogravure printing machine is configured with double-station winding stand, and winding is driven by torque motor. By virtue of automatic tension control, unwinding is achievable. Meanwhile, main motor adopts vector frequency traction control. Tonda motor, Fujikura cylinder, imported reducing valve and swing-type control line are also conductive to unwinding. This mechanism is suitable for high-volume printing, saving energy and costs.

7. Drying and cooling mechanism

External centrifugal fan is adopted for cooling. Three-level adjustment via electrical heated tube and cooling fin is achievable for external heating and cooling. In the meantime, temperature is regulated by intelligent temperature controller. The whole mechanism is power saving.

System Drying Oven Doctor Blade

Face panel Printing plate Rotational stand

Technical Parameters

| Model | FG-RO800 | FG-RO1100 |

| Printing width | 80mm | 1100mm |

| Printing speed | 120m/min. | 120m/min. |

| Diameter of printing plate | 100-350mm | 100-350mm |

| Diameter of printing material | 580mm | 580mm |

| Transverse regulation of printing plate | 30mm | 30mm |

| Printing perimeter | 0.1mm | 0.1mm |

| Total power | 90KW | 100KW |

| Weight | 14000kg | 15000kg |

| Overall dimension | 11400×3200×2900 | 11400×3500×2900 |

Schematic Diagram

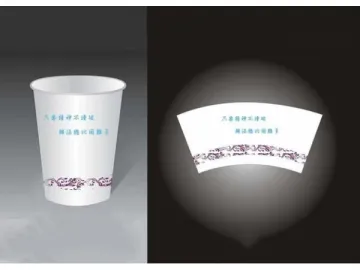

Printed Sample

Links:https://www.globefindpro.com/products/44878.html

-

PE Coated Paper Cup Bottom

PE Coated Paper Cup Bottom

-

Sterilizer Bag

Sterilizer Bag

-

DC-35 Portable Freezer

DC-35 Portable Freezer

-

DC-175 Upright Fridge and Freezer

DC-175 Upright Fridge and Freezer

-

DC-50 Built-In Fridge and Freezer

DC-50 Built-In Fridge and Freezer

-

Water Distiller

Water Distiller

-

Dental Chair Unit, ZC-S300 Dental Chair Package

Dental Chair Unit, ZC-S300 Dental Chair Package

-

Paper Slotting Machine

Paper Slotting Machine

-

Intermittent Rotary Die Cutting Machine

Intermittent Rotary Die Cutting Machine

-

Creasing and Cutting Machine

Creasing and Cutting Machine

-

DC-35P Portable Freezer

DC-35P Portable Freezer

-

Printed Paper Cup Fan

Printed Paper Cup Fan