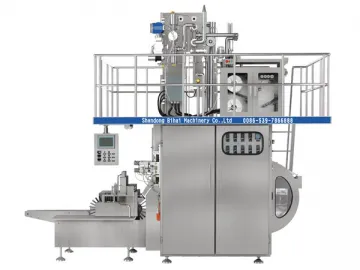

Circulating Air Separator

The TFXH series circulating air separator is especially designed for the separation of low-density particles (hull, dust, etc.) from grains such as wheat, barley, maize, oilseed and others. It is commonly seen in grain depots, flour mills, rice mills, grain distilleries, oil factories, maize processing plants, feed manufacturing factories, etc. Moreover, this machine can be applied both as a stand-alone machine and in combination with vibratory separator, rotary separator or wheat scourer.

Features

1. Reasonable Design

Our product adopts the enclosed design, and the feed mechanism is enclosed outside and opened inside. And the axial pressure door is used to remove light impurities. So, mechanical failure at the feed place is avoided, and the screw conveyor won't be blocked by light impurities.

2. Excellent Performance

Our circulating air separator makes use of a large dust settling chamber to significantly enhance the separation result.

3. Dust-Free Running

This equipment possesses outstanding tightness, and the connection parts are handled by sealing strip. As a result, dust separated from the grains won't spread into the surrounding environment.

Technical Parameters

| Model | Throughput (t/h) | Power (kW) | Overall dimensions (L×W×H, mm) |

| TFXH100 | 16 | 2.2 0.75 | 1670×1000×1680 |

| TFXH150 | 24 | 2.2×2 0.75 | 2556×1000×1680 |

| TFXH200 | 32 | 2.2×2 0.75 | 3100×1000×1680 |

Related Names

Barley Separator | Gravity Separation Machine | Air Classification Machine

Links:https://www.globefindpro.com/products/45023.html