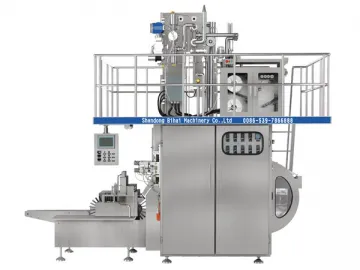

BH2000-1000 Aseptic Carton Filling Machine

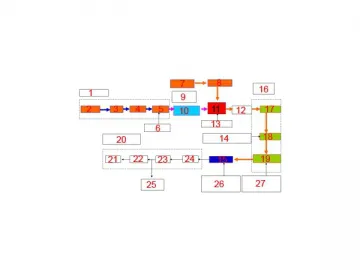

The company spent one year in developing the BH2000-1000 aseptic carton filling machine with the filling volume up to 1000ml and packing speed close to 2000 of 1000ml brick cartons per hour.

The brick carton is made from numerous layers of paper, aluminum, and plastic. It is mainly used to pack milk and still beverages. The aseptic carton filling machine comes in two types: standard and slim. Both types are manufactured from stainless steel. Their electrical elements, pneumatic elements, and other core parts are provided by world-renowned manufacturers. Combined with the advanced control techniques, those components and parts help the machine to achieve high operation stability. The machine's reliable performance is best demonstrated by the fact that it is able to run for dozens of hours without any big mechanical or control fault.

State of the art devices include the cryogenic heat exchanger and PP strip conveyor which own independent intellectual property. Those devices help ensure aseptic packaging. Meanwhile, for secure and tight seal, the middle-seal technique and high-frequency heat sealing treatment are adopted. The machine owns many national patents, and is very popular among customers.

Technical Parameters

| Type | BH2000-1000 aseptic carton filling machine |

| Packing Speed | 1800Cartons/Hour |

| Capacity | 1000ML |

| Form | Aseptic Brick-shaped Carton |

| Shelf Life | 9-12months |

| Air Pressure | 0.8MPa-1.0MPa |

| Installation Power | 26kw(Actual Power 11kw) |

| Measurement | 4000mm×2000mm×4800mm |

| Weight | 4500kg |

| Power Source | 380V/220V 50Hz |

| Air Usage | 3m³/min(0.8MPa-1.0MPa) |

| Steam Usage | 4.5kg/hour (130℃±5℃ 0.17MPa±0.03MPa) |

| Purified Water Usage | 10L/hour |

| H2O2 Usage | 0.5-0.7L per hr(density:35% ~50%) |

| Control System | PLC(HMI) |

| Content Temperature | 15 ℃~25 ℃ |

| Work Environment | temperature5-32 ℃ Relative Humidity20-60% |

| Content Viscosity | Below 200CP |

| Printing Equipment | Ink Jet Printer |

| Connection Dimension | 2500mm(W)×3000mm(H) |

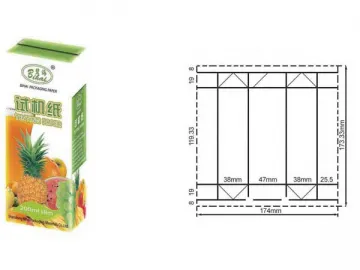

| Carton Box Size | 72mm×71mm×198mm |

| Temperature of Filling Room | 15℃-35℃ |

| Hydraulic Oil/ Lubricating Oil | Made to order |

| Number of Staff Needed | 1 |

Computer automatic control and friendly user-machine interface make accurate filling and simple operation possible. As a matter of fact, the whole filling process only needs one man to accomplish. Additionally, the machine is equipped with ink jet printer which carries out automatic printing on the carton package after filling. There is also steam jetting out to sterilize the filling room and package ends. The flash pasteurization technique ensures nice flavor and good visual effect of the beverage. Thus far, the machine has been exported to dozens of oversea countries, including India, Pakistan, and Iran.

We are a China-based aseptic filling machine manufacturer and supplier. We provide a wide array of products, including tube type ultra-high-temperature beverage instant sterilizer, water treatment equipment, laminated liquid packaging material, and more.

Related Names

Beverage Box Filling Device | Liquid Filling Machine | Fruit Juice Box Filler | Orange Drink Box Filling Machine | Vegetable Juice Filling Equipment

Links:https://www.globefindpro.com/products/45033.html

-

Laminated Liquid Packaging Material

Laminated Liquid Packaging Material

-

Milk Production Line

Milk Production Line

-

Impact Mill

Impact Mill

-

Buried Scraper Conveyor

Buried Scraper Conveyor

-

Soldering Iron

Soldering Iron

-

Ultra-High-Temperature Sterilizer

Ultra-High-Temperature Sterilizer

-

Bucket Elevator

Bucket Elevator

-

YIHUA-853A/946A/946B Series BGA Preheating Station

YIHUA-853A/946A/946B Series BGA Preheating Station

-

60V DC Power Supply

60V DC Power Supply

-

YIHUA-892D SMD Hot Air Rework Station with Soldering Iron

YIHUA-892D SMD Hot Air Rework Station with Soldering Iron

-

BH3000 aseptic carton filling machine

BH3000 aseptic carton filling machine

-

Water Treatment Equipment

Water Treatment Equipment