Ultra-High-Temperature Sterilizer

Features

1. Our ultra-high-temperature sterilizer is able to work continuously for over 16 hours to sterilize still beverages while keeping their original flavor and freshness. In terms of performance, this equipment is on a par with similar European products.

2. Using indirect steam heating method ensures a proper, stable temperature range in which sterilization is carried out. Again thanks to the indirect steam heating, a temperature control accuracy of ±0.1℃ can be achieved.

3. Constant pressure control keeps the sterilized liquid materials fresh without contamination.

4. Real-time monitoring and control of sterilizing temperature by operating staff to achieve desired sterilization effect.

Quality Guarantee

The heat exchanger on this sterilizer is given a three-year quality warranty.

Technical Parameters

| Name | Ultra-High-Temperature Sterilizer |

| Type | TG-UHT-3.0MJ |

| Control System | PID |

| Beverage Types | Milk/Juice/beverage/ vegetable protein drinks/cereal beverage |

| Capacity | 3000L/h |

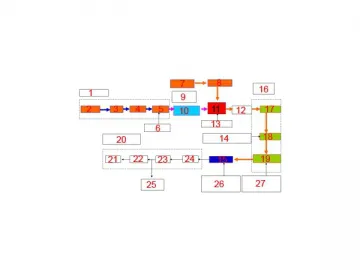

| Processing Flow | 5~65℃ --- 70℃ (for homogenization treatment)---90℃ (30S)---140℃ (4S,10S)---30℃ |

| Steam Pressure | ≥ 6.0 bar |

| Cooled Water Flow Rate | 5t/h ≤ 32℃ |

| Compressed Air Pressure | ≥ 6 bar |

| Steam Consumption | 105 Kg/h |

| Ice Water Flow Rate | 3 T/h ≤ 7℃ (used as an alternative to cooled water) |

| Electric Power | 10.0KW |

| Pure Water Flow Rate | ≥ 2T/h(used as an alternative to cooled water ) |

| Dimension | 4500mm×1900mm×1880mm |

Related Names

Milk Pasteurization Equipment | UHT Sterilizer | Fresh Milk Processing Machine

Links:https://www.globefindpro.com/products/45039.html

-

YIHUA-1501D DC Power Supply

YIHUA-1501D DC Power Supply

-

Automatic Cartoning Machine

Automatic Cartoning Machine

-

YIHUA-882D/882D SMD Hot Air Rework Station with Soldering Iron

YIHUA-882D/882D SMD Hot Air Rework Station with Soldering Iron

-

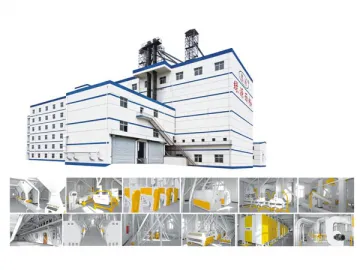

Multi-storey Flour Milling Plant

Multi-storey Flour Milling Plant

-

Maize Grinder

Maize Grinder

-

U-Straw Applicator

U-Straw Applicator

-

Soldering Iron

Soldering Iron

-

Buried Scraper Conveyor

Buried Scraper Conveyor

-

Impact Mill

Impact Mill

-

Milk Production Line

Milk Production Line

-

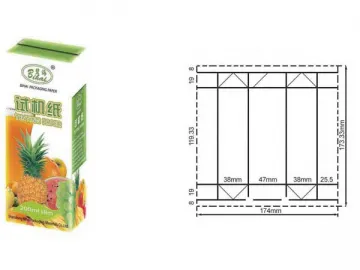

Laminated Liquid Packaging Material

Laminated Liquid Packaging Material

-

BH2000-1000 Aseptic Carton Filling Machine

BH2000-1000 Aseptic Carton Filling Machine