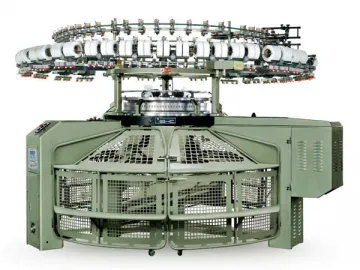

Reverse Terry Knitting Machine

Product Description

The reverse terry knitting machine is equipped with the closed cams on the top and bottom. It is used to manufacture a variety of single jersey terry polar or plush fabrics with high quality, including undyed looped fabric, polyester terrycloth and so forth. Supporting various knitting patterns, it can meet diversified requirements and produce lots of high-quality fabrics. The product is suitable for processing cotton, chemical fiber, blended yarn, real silk, high-elastic polyester silk, artificial wool and other raw materials.

Machine Features and Functions

1. Oil-immersed Structure

The structure can prevents the gear ring from rusting and enables it to rotate more smoothly.

2. Double Stitch Guidance

Such a special design contributes to the stability of operation.

3. Customizable Sinker

To satisfy your requirements, there are various kinds of sinkers for knitting terry fabrics with different pile length from 1.2 to 5.0mm, which helps you to receive the return on investment as soon as possible.

4. Cloth Rolling System

The system is capable of rolling up fabrics evenly without any folds. Moreover, the reverse terry knitting machine possesses an auto stop device which will intelligently shut down the machine if something goes wrong.

5. High-speed Dust Exhausting Fan

It is able to clear away accumulated cotton fiber.

6. Lycra Feeding Unit

With this unit, the machine can manufacture high-quality elastic terry fabrics.

Product Application

Towel, sheet, pillow cover, carpet, home textiles and fabrics for children.

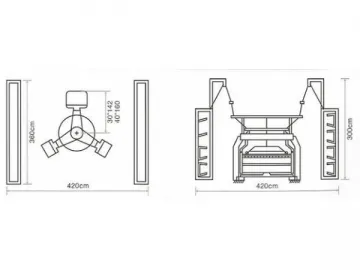

Machine Specification

The terry machines with cylinder diameters from 12" to 64"are available.

You may arrange the raising, stitch, tuck and welt cams in different ways, so as to produce Scottish grid cloth and other pique terry fabrics.

Related Names

Terry Knitting Machine Manufacturer | Towel Knitting Machine | Textile Machine

Links:https://www.globefindpro.com/products/45142.html

-

Sendust Core Inductor for Solar String Inverter

Sendust Core Inductor for Solar String Inverter

-

Pattern Wheel Jacquard Machine

Pattern Wheel Jacquard Machine

-

Auto-Striper Machine

Auto-Striper Machine

-

Double Jersey Machine

Double Jersey Machine

-

Inline Hand Dimmer

Inline Hand Dimmer

-

Double System Flat Knitting Machine

Double System Flat Knitting Machine

-

Interlock /Rib Knit Machine

Interlock /Rib Knit Machine

-

Integrated Transformer and Inductor for Solar Inverter

Integrated Transformer and Inductor for Solar Inverter

-

Open Width Fabric Machine

Open Width Fabric Machine

-

Constant Current/Constant Voltage LED Switch Mode Power Supply

Constant Current/Constant Voltage LED Switch Mode Power Supply

-

Three-phase Hermetically Sealed Oil-immersed Distribution Transformer

Three-phase Hermetically Sealed Oil-immersed Distribution Transformer

-

Single Jersey Machine

Single Jersey Machine