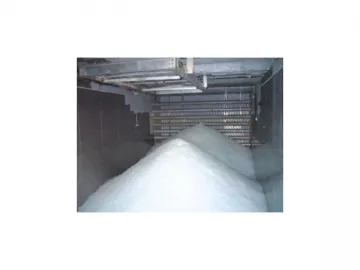

Small Tube Ice Machine

To meet the client's need, we can manufacture small tube ice machine with 1-8 tons daily output.

Features

1. Material: Made of stainless steel, the small tube ice machine is elegant, sanitary, and easy to clean.

2. Control System: Controlled by the microcomputer system, it is easy, safe, and stable in operation.

3. Structure: As a result of the modular design, all the machine parts can be dismantled and assembled. For this reason, this small tube ice making machine is convenient to maintain for the users.

Advantages

1. Scientific Design and Advanced Processing Technology

On the basis of the client's actual application conditions, SHARE small tube ice machine has been scientifically designed, and strictly processed with the internationally advanced technology. The product will be tested before leaving the factory through a test system.

2. High Reliability, Low Failure Rate

80% of the parts is subject to the worldwide well-known brands. Years of research and practice have proven that the product can be continuously operated without failure. It maintains favorable operation and stable output in the environment temperature of 5℃ to 40℃. Far more than that, the well-crafted machine even works normally in the hostile environment where the temperature range is from -5℃ to 56℃.

3. Safety and Sanitation

All machine parts that will contact with water are manufactured with SUS304 or SUS316L stainless steel or PE materials. The tube ice made by this machine is clean, and odor-free. Hygienic standard of our machine is in line with HACCP and PDA.

4. Modular Design, Easy Maintenance

The small tube ice machine with modular design can be easily maintained. You can install it into a standard container, for the convenient use in the occasions where tube ices are required at any time.

5. Full-automatic Control

Our machine applies PLC and HMI control system that can be operated with one key. For several machines in parallel, we can provide long-distance control interfaces so as to realize the centralized control.

| Item | Unit | 1T Tube Ice Machine | 2T Tube Ice Machine | 3T Tube Ice Machine | |

| Input Power | V/P/Hz | 380V/3P/50Hz | 380V/3P/50Hz | 380V/3P/50Hz | |

| Rated Current | A | 14A | 17A | 22A | |

| Refrigerant | / | R22/R404A//R134A/R717 | R22/R404A//R134A/R717 | R22/R404A//R134A/R717 | |

| Tube Ice Output | Kg/day | 1000 | 2000 | 3000 | |

| Temperature | Environment Temperature | ℃ | 25 | 25 | 25 |

| Water Temperature | ℃ | 20 | 20 | 20 | |

| Operating Power | Total Operating Power | Kw | 7 | 10 | 11 |

| Installation Power | Kw | 10 | 12 | 14 | |

| Reducer Power | Kw | 0.37 | 0.37 | 0.37 | |

| Water Pump Power | Kw | 0.55 | 0.55 | 0.55 | |

| Compressor | Manufacturer | Copeland | Copeland | Copeland | |

| Necessary Refrigerating Capacity | Kw | 5.58 | 11.16 | 16.8 | |

| Refrigerating Capacity of Machine Unit | Kw | 9.7 | 15.49 | 24.5 | |

| Operating Power | Kw | 5.47 | 7.1 | 8.9 | |

| Compressor COP/EER | Kw/kw | 1.77 | 2.18 | 2.6 | |

| Horsepower | Hp | 5 | 10 | 15 | |

| Condenser | Fan Power | Kw | 0.7 | 1.1 | 1.2 |

| Cooling Method | Air cooling | Air cooling | air or water cooling | ||

| Overall Dimension | Machine Size | (L×W×H) (mm) | 1, 400×1, 000×1, 800 | 1, 600×1, 000×2, 000 | 1, 700×1, 000×2, 000 |

| Size of Ice Container | (L×W×H) (mm) | Configured as per requirement | Configured as per requirement | Configured as per requirement | |

| Water Pipe Size | 1/2" | 1/2" | 1/2" | ||

| Tube Ice | Tube Ice Diameter | mm | ¢22, ¢29, ¢35, ¢41 Inner Hole Diameter: 3mm-15mm | ¢22, ¢29, ¢35, ¢41 Inner Hole Diameter: 3mm-15mm | ¢22, ¢29, ¢35, ¢41 Inner Hole Diameter: 3mm-15mm |

| Tube Ice Height | mm | 25-50 | 25-50 | 25-50 | |

| Appearance | ℃ | Hollow tube, transparent, sanitary | Hollow tube, transparent, sanitary | Hollow tube, transparent, sanitary | |

| Weight | Machine Weight | Kg | 700 | 900 | 1, 200 |

| Operating Weight | Kg | 850 | 1, 000 | 1, 400 | |

| Water Supply Pressure | PA | 0.1MPa-0.5MPa | 0.1MPa-0.5MPa | 0.1MPa-0.5MPa | |

| Installation Site Requirement | m2 | ≥9 m2 | ≥9 m2 | ≥15 m2 | |

| Machine Structure | All air cooling condensers excluding that of ZT1.0T apply the external installation; External installation for cooling tower and evaporative cooling; The evaporators and condensers of the machine models above ZT10.0T, adopt the separate structure for the convenient transportation. | ||||

| Model Instruction | ZT stands for tube ice machine, and the following are the figures of tons; The refrigerant type has been marked; Cooling methods: A stands for air cooling, W for water cooling, and E for evaporative cooling. | ||||

| Item | Unit | 5T Tube Ice Machine | 8T Tube Ice Machine | |

| Temperature | Environment Temperature | ℃ | 25 | 25 |

| Water Temperature | ℃ | 20 | 20 | |

| Operating Power | Total Operating Power | Kw | 21 | 32 |

| Installation Power | Kw | 30 | 40 | |

| Reducer Power | Kw | 0.37 | 0.55 | |

| Water Pump Power | Kw | 0.55 | 1.2 | |

| Compressor | Manufacturer | Bitzer | Bitzer | |

| Necessary Refrigerating Capacity | Kw | 28 | 44.6 | |

| Refrigerating Capacity of Machine Unit | Kw | 37.5 | 55 | |

| Operating Power | Kw | 18.5 | 27 | |

| Compressor COP/EER | Kw/kw | 2.03 | 2.04 | |

| Horsepower | Hp | 25 | 40 | |

| Condenser | Air Cooling Power | Kw | 1.6 | 3.5 |

| Water Cooling Power | Kw | 1.12 | 2.95 | |

| Cooling Method | Air or water cooling | Air or water cooling | ||

| Overall Dimensions | Size of Machine | (L×W×H) (mm) | 1,700×1,500×2,200 | 2,000×1,500×2,500 |

| Size of Ice Container | (L×W×H) (mm) | Configured as per requirement | Configured as per requirement | |

| Water Pipe Size | 1/2" | 1/2" | ||

| Tube Ice | Tube Ice Diameter | mm | ¢22, ¢29, ¢35, ¢41 Inner Hole Diameter Range: 3mm-15mm | ¢22, ¢29, ¢35, ¢41 Inner Hole Diameter Range: 3mm-15mm |

| Tube Ice Height | mm | 25-50 | 25-50 | |

| Appearance | ℃ | Hollow tubular, transparent, sanitary | Hollow tubular, transparent, sanitary | |

| Weight | Machine Weight | Kg | 1400 | 2100 |

| Operating Weight | Kg | 1650 | 2400 | |

| Water Supply Pressure | PA | 0.1MPa-0.5MPa | 0.1MPa-0.5MPa | |

| Installation Site Requirement | m2 | ≥15 m2 | ≥15 m2 | |

| Machine Structure | All air cooling condensers excluding that of ZT1.0T apply the external installation; External installation for cooling tower and evaporative cooling; The evaporators and condensers of the machine models above ZT10.0T, adopt the separate structure for the convenient transportation. | |||

| Model Instruction | ZT stands for tube ice machine, and the following are the figures of tons; The type of refrigerant is marked; Cooling methods: A stands for air cooling, W for water cooling, and E for evaporative cooling. | |||

Related Names

Freestanding Ice Maker | Small Ice Maker | Tube Ice Device

Links:https://www.globefindpro.com/products/45246.html

-

Plate Ice Machine

Plate Ice Machine

-

Cube Ice Machine

Cube Ice Machine

-

Worm Gearmotor

Worm Gearmotor

-

2000mm Three-layer/Five-layer Co-extrusion High Speed PE Cast Stretch Film Line

2000mm Three-layer/Five-layer Co-extrusion High Speed PE Cast Stretch Film Line

-

Automatic Ice Storage Bin

Automatic Ice Storage Bin

-

Parallel Shaft Helical Gearmotor

Parallel Shaft Helical Gearmotor

-

Sn50Pb50 Tin Lead Solid Solder Wire and Solder Bar

Sn50Pb50 Tin Lead Solid Solder Wire and Solder Bar

-

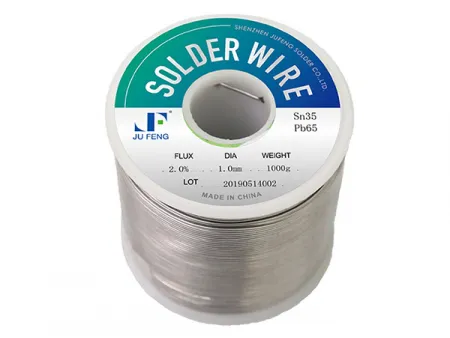

Sn35Pb65 Tin Lead Solder Wire and Solder Bar

Sn35Pb65 Tin Lead Solder Wire and Solder Bar

-

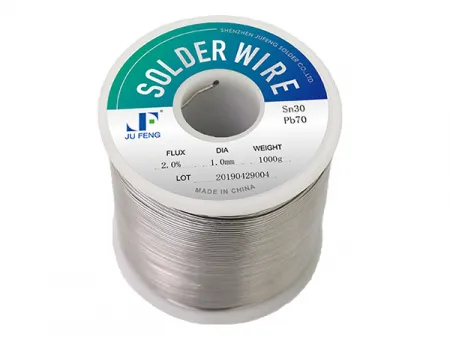

Sn30Pb70 Tin Lead Solder Wire and Solder Bar

Sn30Pb70 Tin Lead Solder Wire and Solder Bar

-

Automatic Ice Delivery System

Automatic Ice Delivery System

-

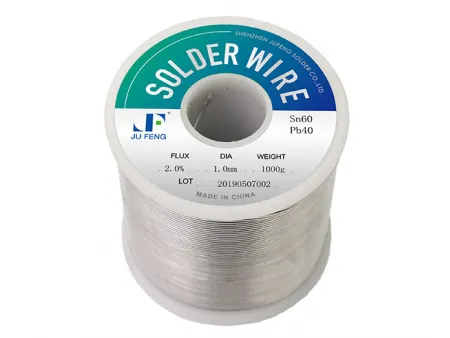

Sn60Pb40 Water-Soluble Tin Lead Solder Wire and Solder Bar

Sn60Pb40 Water-Soluble Tin Lead Solder Wire and Solder Bar

-

Sea Water Flake Ice Machine

Sea Water Flake Ice Machine