CPET/OPET Cast Film Extrusion Line

Using the PET as the raw material, our CPET and OPET cast film extrusion line can produce environmental friendly CPET and OPET films. The CPET film is produced by means of tape casting. The OPET film production is accomplished via tape casting along with uniaxial stretching. In some areas, the two kinds of film can substitute for the PVC film, BOPET film, BOPP film and other films for packaging, enormously reducing the equipment cost and film production cost.

Features of Our Production Line

1. Adopting the single-screw or double-screw extruder, the cast film extrusion line enables the production of cast film with single-layer, double-layer or three-layer co-extruded structure.

2. Allowing for the particularity of PET material or the characteristic of the modified PET material, we introduce the particularly-designed extrusion processing technology and through a series of devices and production procedures as dehumidification drying, automatic weighing and feeding, plasticizing extruder, T type die for tape casting, molding and sizing systems, automatic thickness-measuring system, preheating and stretching-setting devices, surface treatment device, trimming and edge processing devices as well as automatic winding device, this production line can produce high-quality films with special performance and applicable to various fields.

3. It also can produce customized films according to the specific requirements of customers.

Characteristics of CPET and OPET Films

Based on the special performances of film required by application fields, the CPET and OPET films produced by our cast film extrusion line do not only possess admirable physical and mechanical properties, but also come with excellent optical property, high transparency, low haze, good glossiness, fine heat stability, low heat shrinkage, smooth and bright surface as well as the resistance to stripping, light and ageing. Moreover, the OPET film is also characterized by high uniaxial tensile strength and uniaxial orientation, suitable for the application in special fields.

Main Applications of CPET and OPET Films

1. Tinplate laminated film: After laminated with the tinplate, the CPET and OPET films produced by our cast film extrusion line can be used as the packaging of various kinds of food and beverage.

2. Electronic component packaging: They can be made as the anti-static packaging of shielded sensitive electronic components, circuit boards, communication device and other electronic products.

3. Medicine packaging: Primarily, they are applied to the packaging of the medicine that is made into tablets.

4. Base film of chemical coating: For purpose of improving the surface performance of PET film as well as bettering the flexibility of printing and the adhesion of vacuum aluminum coating, adopting corona treatment to enhance the rapid decline of the surface tension in high-temperature and high-humidity environment is avoided for producing this base film by our cast film extrusion line. In this way, the thickness of the aluminum coating is also increased.

5. Heat shrinkable film: The CPET and OPET films can be made into the heat shrinkable PET film. This film is a new-type heat shrinkable packaging material. Owing to the advantages as easy recycling, no toxicity, no odor, excellent mechanical property and environmental protection, it has been an ideal substitute for the heat shrinkable PVC film.

6. Base film of solar film (glass film): Produced by our cast film extrusion line, the two films also can be processed to be the base film of solar film which is a PET film with multi-layer structure and glued onto the flat glass surface. It is a hi-tech energy-saving product that can effectively control solar thermal radiation and improve glass strength, belonging to a new kind of energy-saving building material. Except improving the strength and property of glass, this film also ensures that the glass is energy-saving, heat insulated and preserved, anti-explosion, UV-proof, safe and attractive in appearance with shielding function. Basically, it is applied to the door, window, partition and roof of autos and buildings.

7. The CPET film manufactured by our cast film extrusion line is also available in aspects of the low temperature radiant electro-thermal film, insulation of motors and generators as well as the insulating layer of wires and cables.

Links:https://www.globefindpro.com/products/45257.html

-

Helical Worm Gearmotor

Helical Worm Gearmotor

-

Five-layer Co-extrusion PE Food Wrap Extrusion Line with Double Shaft Winder

Five-layer Co-extrusion PE Food Wrap Extrusion Line with Double Shaft Winder

-

3000mm Three-layer/Five-layer Co-extrusion PE Cast Stretch Film Line

3000mm Three-layer/Five-layer Co-extrusion PE Cast Stretch Film Line

-

PVDF/ETFE Cast Film Extrusion Line

PVDF/ETFE Cast Film Extrusion Line

-

PVC Embossed Film Extrusion Line

PVC Embossed Film Extrusion Line

-

Stepless Speed Variator

Stepless Speed Variator

-

Transparent PVC Packaging Film Extrusion Line

Transparent PVC Packaging Film Extrusion Line

-

Spiral Bevel Gear Reducer

Spiral Bevel Gear Reducer

-

Parallel Shaft Helical Gearmotor

Parallel Shaft Helical Gearmotor

-

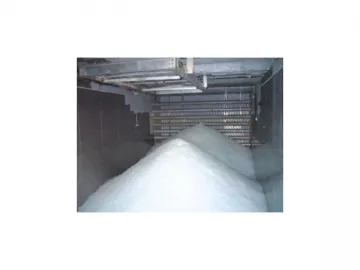

Automatic Ice Storage Bin

Automatic Ice Storage Bin

-

2000mm Three-layer/Five-layer Co-extrusion High Speed PE Cast Stretch Film Line

2000mm Three-layer/Five-layer Co-extrusion High Speed PE Cast Stretch Film Line

-

Worm Gearmotor

Worm Gearmotor