Five-layer Co-extrusion PE Food Wrap Extrusion Line with Double Shaft Winder

The PE food wrap extrusion line with double shaft winder is provided for producing the self-adhesive five-layer PE food wrap film via the extrusion technology by utilizing the extruder. Before the production, the main raw material, LLDPE (linear low density polyethylene), should be evenly mixed with multiple grades of auxiliary materials.

Features of Our Production Line

1. It comes with the five-layer distributor, automatic double-shaft winder, touch screen and the PLC control system. The whole machine runs stably and reliably.

2. The electrostatic film winding system can be provided as the option and the adhesive tape is needless. Therefore, a number of materials and labor costs are saved.

3. This PE food wrap extrusion line is also provided with the protection switch with correlative light curtain as well as the cutter controlled mechanically and electrically so as to insure the safety of people during the production.

Characteristics of PE Food Wrap Film

This film is completely in conformity with GB10457-2009 Hygienic Standard for Polyethylene Products Used as Food Containers and Tableware and also compatible with national quality control standards and international environmental hygiene standards. It is a safe, eco-friendly, sanitary, reliable, non-poisonous and harmless product with anti-fog, anti-loose, rainproof, dustproof, self-adhesive, tension resistant, and puncture resistant properties as well as other wonderful characteristics.

Main Applications of PE Food Wrap Film

Superbly manufactured by our PE food wrap extrusion line, this film is vastly used in homes, supermarkets, hotels, restaurants and food factories for retaining the freshness of the cooked food, raw food, meats, vegetables, fruits, seafood, etc.

Parameters of Our Production Line

| Model (mm) SJLM-BX-Z | 1200 | 1500 | 1800 |

| Screw Diameter (mm) | 55/80/55 | 55/90/65 | 65/100/65 |

| Length-diameter Ratio of Screw (L/D) | 32:1 | 32:1 | 32:1 |

| Width of Die (mm) | 1550 | 1900 | 2200 |

| Width of Finished Film (mm) | 1200 (300×4 rolls) | 1500 (300×5 rolls) | 1800 (300×6 rolls) |

| Thickness of Finished Film (mm) | 0.01-0.03 | 0.01-0.03 | 0.01-0.03 |

| Structure of Film | A/C/B/C/A | A/C/B/C/A | A/C/B/C/A |

| Maximum Extrusion Capacity (kg/h) | 170 | 200 | 240 |

| Linear Speed of Machine (m/minute) | 200 | 200 | 200 |

| Total Installed Power (KW) | 200 | 240 | 300 |

| Overall Dimensions (L×W×H) (m) | 12×7×5.5 | 13×7×5.5 | 15×8×6 |

| Weight (T) | 22 | 25 | 30 |

Note: The above data are subject to change without prior notice.

Links:https://www.globefindpro.com/products/45260.html

-

3000mm Three-layer/Five-layer Co-extrusion PE Cast Stretch Film Line

3000mm Three-layer/Five-layer Co-extrusion PE Cast Stretch Film Line

-

PVDF/ETFE Cast Film Extrusion Line

PVDF/ETFE Cast Film Extrusion Line

-

PVC Embossed Film Extrusion Line

PVC Embossed Film Extrusion Line

-

Stepless Speed Variator

Stepless Speed Variator

-

1500mm Three-layer Co-extruded PE Cast Stretch Film/Silage Film Line

1500mm Three-layer Co-extruded PE Cast Stretch Film/Silage Film Line

-

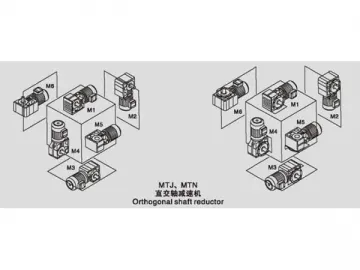

Helical Bevel Gearmotor

Helical Bevel Gearmotor

-

Helical Worm Gearmotor

Helical Worm Gearmotor

-

CPET/OPET Cast Film Extrusion Line

CPET/OPET Cast Film Extrusion Line

-

Transparent PVC Packaging Film Extrusion Line

Transparent PVC Packaging Film Extrusion Line

-

Spiral Bevel Gear Reducer

Spiral Bevel Gear Reducer

-

Parallel Shaft Helical Gearmotor

Parallel Shaft Helical Gearmotor

-

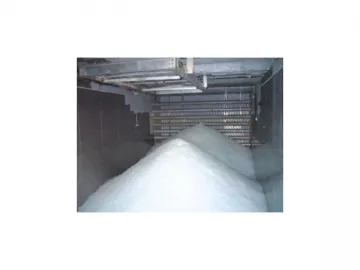

Automatic Ice Storage Bin

Automatic Ice Storage Bin