1500mm Three-layer Co-extruded PE Cast Stretch Film/Silage Film Line

Having LLDPE (linear low density polyethylene) as the main raw material, the three-layer co-extruded PE cast stretch film and silage film line also utilizes various grades of resins as the auxiliary materials to produce film products via the extrusion technology conducted by the extruder.

The three-layer stretch film produced by it comes with self-adhesive property as well as single sticky surface or double sticky surfaces. Through adopting the special formula and technology for producing silage films, it enables the fabrication of high-quality silage films.

Features of Our Production Line

1. The up-to-date robot device is optional for this PE cast stretch film and silage film line to realize automatic shaft charging and paper tube charging. Therefore, the labor cost is saved.

2. It is equipped with three-layer co-extruded and automatic film roll changing systems and characterized by compact structure, high performance cost ratio, attractive appearance as well as remarkable performance.

Characteristics of Films Produced by Our Production Line

1. The films produced by our PE cast stretch film and silage film line have high tensile strength along with strong resistance to puncture and impact.

2. The goods will be tightly packaged into an entirety due to the splendid elastic resilience and self-adhesive property of the films. Also, the phenomenon as loosening or dropping or dust pollution can be effectively avoided during the transportation.

3. By using these films, the packaged goods seem more elegant and attractive as a result of fine transparency and extensibility of films.

Main Applications of the PE Cast Stretch Film and the Silage Film

1. The PE cast stretch film produced by our PE cast stretch film and silage film line is a better substitute for the heat shrinkable packaging film. Basically, it is extensively applied to the containerized palletizing of bulk goods.

2. The silage is more and more crucial in the modern animal husbandry. The bale packing is a new silage storage pattern which can retain the moisture and energy of silage, improve the nutrition value of silage and make the silage readily digested.

By using the silage film, the silage is able to be preserved till the winter and less affected by the weather. Besides, the storage and transportation are much easier, and the silage loss and cost are reduced, thus increasing the economic benefit.

Parameters of Our Production Line

| Model (mm) SJLM-CR-Z | It produces the 1500mm three-layer co-extruded PE cast stretch film and silage film. | ||

| Screw Diameter (mm) | 65/100/65 | 65/110/80 | 80/125/80 |

| Length-diameter Ratio of Screw (L/D) | 32:1 | 32:1 | 32:1 |

| Width of Die (mm) | 1800 | 1800 | 1800 |

| Width of Finished Film (mm) | 1500 (500×3 rolls) | 1500 (500×3 rolls) | 1500 (500×3 rolls) |

| Thickness of Finished Film (mm) | 0.015-0.05 | 0.015-0.05 | 0.015-0.05 |

| Structure of Film | A/B/C | A/B/C | A/B/C |

| Maximum Extrusion Capacity (kg/h) | 300 | 380 | 550 |

| Linear Speed of Machine (m/minute) | 145 | 200 | 280 |

| Total Installed Power (KW) | 250 | 330 | 440 |

| Overall Dimensions (L×W×H) (m) | 13×8×6 | 14×8×6 | 15×8×6 |

| Weight (T) | 22 | 25 | 28 |

Note: The above data are subject to change without prior notice.

Links:https://www.globefindpro.com/products/45265.html

-

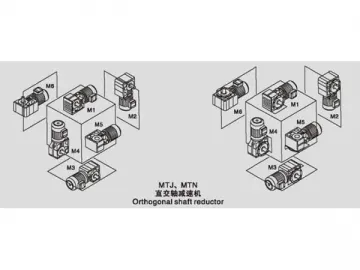

Helical Bevel Gearmotor

Helical Bevel Gearmotor

-

Helical Gearmotor

Helical Gearmotor

-

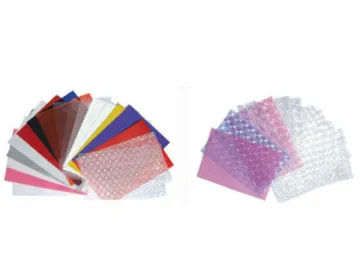

Single Layer /Multi-layer Co-extrusion PEVA Cast Embossed Film Line

Single Layer /Multi-layer Co-extrusion PEVA Cast Embossed Film Line

-

Planetary Gearbox

Planetary Gearbox

-

Eco-friendly 3D EVA/PU Film and Sheet Extrusion Line

Eco-friendly 3D EVA/PU Film and Sheet Extrusion Line

-

PE Breathable Film Extrusion Line

PE Breathable Film Extrusion Line

-

Stepless Speed Variator

Stepless Speed Variator

-

PVC Embossed Film Extrusion Line

PVC Embossed Film Extrusion Line

-

PVDF/ETFE Cast Film Extrusion Line

PVDF/ETFE Cast Film Extrusion Line

-

3000mm Three-layer/Five-layer Co-extrusion PE Cast Stretch Film Line

3000mm Three-layer/Five-layer Co-extrusion PE Cast Stretch Film Line

-

Five-layer Co-extrusion PE Food Wrap Extrusion Line with Double Shaft Winder

Five-layer Co-extrusion PE Food Wrap Extrusion Line with Double Shaft Winder

-

Helical Worm Gearmotor

Helical Worm Gearmotor