Single Layer /Multi-layer Co-extrusion PEVA Cast Embossed Film Line

Having the LLDPE (linear low density polyethylene), LDPE (low density polyethylene), HDPE (high density polyethylene) and the EVA (ethylene-vinyl acetate copolymer) as the main raw materials, this PEVA cast embossed film line is provided for producing embossed films and the base films of hygienic materials.

Features of Our Production Line

1. It has the advantages as less production procedures, small energy consumption and low cost by utilizing two sets or more than two sets of extruders to achieve co-extrusion during the production of multi-layer films.

2. It is controlled by the PLC system and the touch screen.

3. Due to the adoption of up-to-date winding tension control unit, the tension measurement is more precise, stable and reliable.

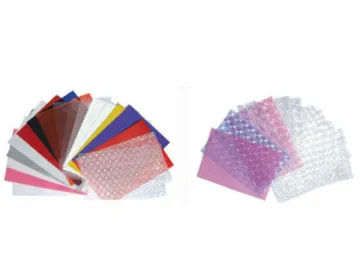

Characteristics of PEVA Cast Embossed Film

1. By utilizing the multi-layer co-extrusion casting technology, our PEVA cast embossed film line can make multiple materials with different characteristics laminated together during the extrusion. Hence, the PEVA cast embossed film possesses excellent complementary properties as well as special performance and appearance. It is remarkable in transparency, permeability resistance, pollution resistance, UV resistance, fragrance and heat preservation, heat sealing property in low temperature, the barrier property against oxygen and damp as well as the mechanical properties like strength, stiffness and rigidity.

2. The thickness uniformity of this film is more desirable.

3. Fine transparency and heat sealing property is perfectly represented in this film.

4. Excellent internal stress and fine printing effect is realized.

Main Applications of PEVA Cast Embossed Film

1. Hygienic products: The film produced by the PEVA cast embossed film line can be used in the medical surgical gowns, disposable bedspreads, sanitary napkins, baby diapers, pet cushions, shoe covers, head caps, etc.

2. Commodities: It is usable for various table cloths, gloves, aprons, shower curtains, garment bags, raincoats, beach umbrellas, chair covers, wardrobe covers, blanket covers, etc.

3. Industrial products: For the typewriter covers, computer covers, air conditioner covers, photocopier covers and the dustproof covers for various machines, this film is also applicable.

Parameters of Our Production Line

| Model (mm) SJLM-YW-Z | 1600 | 2200 | 1600 | 2200 |

| Screw Diameter (mm) | 125 | 135 | 80/110 | 90/110 |

| Length-diameter Ratio of Screw (L/D) | 32:1 | 32:1 | 32:1 | 32:1 |

| Width of Die (mm) | 1900 | 2500 | 1900 | 2500 |

| Width of Finished Film (mm) | 1600 | 2200 | 1600 | 2200 |

| Thickness of Finished Film (mm) | 0.02-0.20 | 0.02-0.20 | 0.02-0.20 | 0.02-0.20 |

| Structure of Film | A | A | A/B, A/B/A | A/B, A/B/A |

| Maximum Extrusion Capacity (kg/h) | 320 | 450 | 320 | 450 |

| Linear Speed of Machine (m/minute) | 120 | 120 | 120 | 120 |

| Total Installed Power (KW) | 230 | 280 | 240 | 330 |

| Overall Dimensions (L×W×H) (m) | 15×6×4.2 | 16×7×4.5 | 15×8×4.2 | 16×8×4.5 |

| Weight (T) | 30 | 35 | 35 | 40 |

Note: The above data are subject to change without prior notice.

Links:https://www.globefindpro.com/products/45268.html

-

Planetary Gearbox

Planetary Gearbox

-

Eco-friendly 3D EVA/PU Film and Sheet Extrusion Line

Eco-friendly 3D EVA/PU Film and Sheet Extrusion Line

-

PE Breathable Film Extrusion Line

PE Breathable Film Extrusion Line

-

Shaft Mounted Gearbox

Shaft Mounted Gearbox

-

Waste Plastic Granulator

Waste Plastic Granulator

-

High Power Gear Reducer

High Power Gear Reducer

-

Helical Gearmotor

Helical Gearmotor

-

Helical Bevel Gearmotor

Helical Bevel Gearmotor

-

1500mm Three-layer Co-extruded PE Cast Stretch Film/Silage Film Line

1500mm Three-layer Co-extruded PE Cast Stretch Film/Silage Film Line

-

Stepless Speed Variator

Stepless Speed Variator

-

PVC Embossed Film Extrusion Line

PVC Embossed Film Extrusion Line

-

PVDF/ETFE Cast Film Extrusion Line

PVDF/ETFE Cast Film Extrusion Line