PE Breathable Film Extrusion Line

The PE breathable film extrusion line produces the PE breathable film by mainly using the PE breathable colloidal particles. It adopts the most advanced technologies in the world, among which the extrusion, cast uni-axial stretching technologies play important parts in the whole production.

Features of Our Production Line

1. It is equipped with the on-line extrusion and recycling system for recycling the edge trim.

2. The vertical or horizontal stretching unit sophisticatedly designed enables convenient and safe film hauling-off. The stretch ratio is adjustable according to actual needs.

3. The complete PE breathable film extrusion line is equipped with the touch screen, PLC control system and various specially-designed protection switches. Hence, the operation is more simple, safe and convenient.

4. The up-to-date winding tension control unit provides precise, stable and reliable tension measurement.

5. The on-line slitting unit or the on-line printing unit is optional to achieve automated flow production. By this way, the labor cost will be also saved.

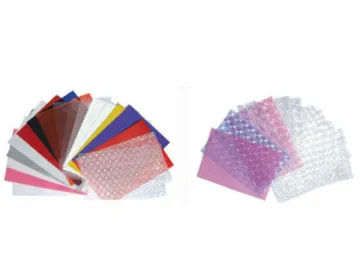

Characteristics of PE Breathable Film

1. Produced by our PE breathable film extrusion line, it is a new generation of breathable film with unique cellular structure. These high-density micropores distributed on the surface of film have breathable and waterproof functions for they can prevent liquid leakage but let the vapor or other gas molecules pass through. For this reason, this film is applicable to the sanitary napkin and the baby diaper to make the water vapor in the water absorption layer exhaust and make people feel comfortable.

2. It also features softness, non-toxicity, pure whiteness, high purity, etc.

Main Applications of PE Breathable Film

1. Hygienic products: This film produced by the PE breathable film extrusion line can be used in the sanitary napkin, sanitary pad, baby diaper, etc.

2. Medical supplies: It can be applied in the medical surgical isolation gown and the disposable bedspread.

3. Commodities: It is usable for the raincoat, glove, raglan sleeve, waterproof cloth and so on.

4. Building materials: It also can be used as the breathable and waterproof material, anti-dew film, etc.

Parameters of Our Production Line

| Model (mm) SJLM-TQ-Z | 1700 | 2000 | 2200 |

| Screw Diameter (mm) | 135 | 135 | 150 |

| Length-diameter Ratio of Screw (L/D) | 35:1 | 35:1 | 35:1 |

| Width of Die (mm) | 2150 | 2500 | 2800 |

| Width of Finished Film (mm) | 1700 | 2000 | 2200 |

| Gram Weight of Finished Film (g/m2) | 20-40 | 20-40 | 20-40 |

| Maximum Extrusion Capacity (kg/h) | 380 | 450 | 550 |

| Linear Speed of Machine (m/min) | 150 | 150 | 150 |

| Total Installed Power (KW) | 450 | 550 | 580 |

| Overall Dimensions (L×W×H)(m) | 23×11×4.5 | 24×12×4.5 | 25×12×4.5 |

| Weight (T) | 50 | 60 | 65 |

Note: The above data are subject to change without prior notice.

Links:https://www.globefindpro.com/products/45276.html

-

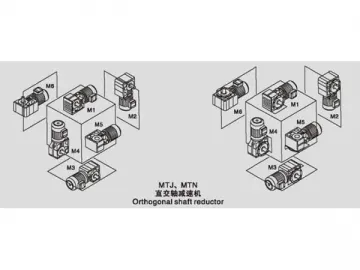

Shaft Mounted Gearbox

Shaft Mounted Gearbox

-

Waste Plastic Granulator

Waste Plastic Granulator

-

High Power Gear Reducer

High Power Gear Reducer

-

Five-layer Co-extrusion PE Food Wrap Extrusion Line with Three Shaft Winder

Five-layer Co-extrusion PE Food Wrap Extrusion Line with Three Shaft Winder

-

Stretch Film Slitter Rewinder

Stretch Film Slitter Rewinder

-

Triple Pass Dryer

Triple Pass Dryer

-

Eco-friendly 3D EVA/PU Film and Sheet Extrusion Line

Eco-friendly 3D EVA/PU Film and Sheet Extrusion Line

-

Planetary Gearbox

Planetary Gearbox

-

Single Layer /Multi-layer Co-extrusion PEVA Cast Embossed Film Line

Single Layer /Multi-layer Co-extrusion PEVA Cast Embossed Film Line

-

Helical Gearmotor

Helical Gearmotor

-

Helical Bevel Gearmotor

Helical Bevel Gearmotor

-

1500mm Three-layer Co-extruded PE Cast Stretch Film/Silage Film Line

1500mm Three-layer Co-extruded PE Cast Stretch Film/Silage Film Line