1200-1800mm PVC Cling Film Extrusion Line with Double Shaft Winder

By using the PVC resin powder as the main raw material evenly mixed with various grades of auxiliary materials, the PVC cling film extrusion line with double shaft winder can produce the self-adhesive PVC cling film via the procedure of plasticizing extrusion implemented by the extruder.

Features of Our Production Line

1. As it is equipped with high-efficiency plasticizing screws and supplemented with the advanced production technology, the fisheye phenomenon is splendidly eliminated.

2. The specially-designed moulds and the extrusion molding technology enable the stability of high-speed production as well as the high qualified rate of products.

3. The whole machine comes with the touch screen and PLC control system. Besides, the various particularly designed safety switches make for more convenient and safe operation.

Strengths of PVC Cling Film Produced by Our Production Line

1. The additives harmful to human health and detrimental to the environment will not be used in the process of producing the PVC cling film. Thanks to our PVC cling film extrusion line, the PVC cling film possesses the strengths as high tensile strength, outstanding anti-fog effect, high transparency, fine surface glossiness, etc.

2. It is safe and sanitary to use the PVC cling film for food packaging. It keeps the freshness of food, prevents automatic food decrement, saves the food from being dried or tainted by other odors, fully displays the original feature and glamour of the food and makes the food more appealing.

Main Applications of PVC Cling Film

The PVC cling film produced by our PVC cling film extrusion line is extensively applied to supermarkets, hotels, restaurants, bakeries and homes for packaging and preserving of the food requiring refrigeration, such as the vegetable, fruit, cold dish, raw meat, the food made of flour, etc.

Parameters of Our Production Line

| Model (mm) SJLM-BX-Z | 1200 | 1500 | 1800 |

| Screw Diameter (mm) | 90 | 115 | 130, 115 |

| Length-diameter Ratio of Screw (L/D) | 28:1 | 28:1 | 28:1 |

| Width of Die (mm) | 1700 | 2000 | 2350 |

| Width of Finished Film (mm) | 1200 (300×4 rolls) | 1500 (300×5 rolls) | 1800 (300×6 rolls) |

| Thickness of Finished Film (mm) | 0.01-0.015 | 0.01-0.015 | 0.01-0.018 |

| Maximum Extrusion Capacity (kg/h) | 200 | 300 | 500/350 |

| Linear Speed of Machine (m/minute) | 160 | 200 | 200 |

| Total Installed Power (excluding the batching system) (KW) | 150 | 220 | 250 |

| Overall Dimensions (L×W×H) (m) | 14×7×4 | 15×7.5×4 | 15×8×4 |

| Weight (T) | 25 | 30 | 35 |

Note: The above data are subject to change without prior notice.

Links:https://www.globefindpro.com/products/45283.html

-

1800-2100mm PVC Cling Film Extrusion Line with Three Shaft Winder

1800-2100mm PVC Cling Film Extrusion Line with Three Shaft Winder

-

Double-layer/Three-layer Co-extruded Film Lamination Line

Double-layer/Three-layer Co-extruded Film Lamination Line

-

Lime Rotary Kiln

Lime Rotary Kiln

-

Single-side/Double-side High Speed Paper Film Coating Lamination Line

Single-side/Double-side High Speed Paper Film Coating Lamination Line

-

Impact Hammer Crusher

Impact Hammer Crusher

-

EVA Solar Cell Encapsulation Film Extrusion Line

EVA Solar Cell Encapsulation Film Extrusion Line

-

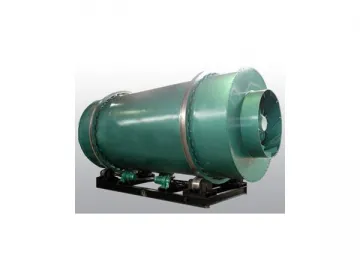

Triple Pass Dryer

Triple Pass Dryer

-

Stretch Film Slitter Rewinder

Stretch Film Slitter Rewinder

-

Five-layer Co-extrusion PE Food Wrap Extrusion Line with Three Shaft Winder

Five-layer Co-extrusion PE Food Wrap Extrusion Line with Three Shaft Winder

-

High Power Gear Reducer

High Power Gear Reducer

-

Waste Plastic Granulator

Waste Plastic Granulator

-

Shaft Mounted Gearbox

Shaft Mounted Gearbox