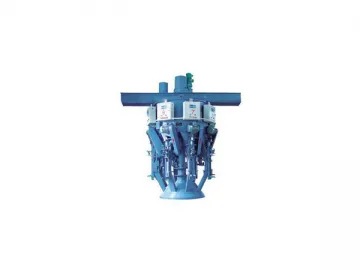

Rolling Machine

Our rolling machine is a newly developed cement grinding mill. It integrates functions such as roller pressing, material scattering, classification, drying, and powder separating. When used with a ball mill, the roller mill can be used for many grinding purposes, like pre-crushing, mixture grinding, semi-finished product grinding, and finished product grinding.

Due to the innovative grinding principle, the rolling machine and its derivative grinding systems can reduce electricity consumption by 50-100%, and improve productivity by 100-300%. It is an ideal choice for old grinding equipment updating.

After roller pressing, 20-35% of the material comes with particle size of 0.08mm, and 65-85% has particle size less than 20mm. There will also be many tiny cracks on the produced material due to the high intensive pressing force, which largely improves the grindability of materials.

Main Features

1. Due to the adoption of heat overlay welding technique, the wearing resistant layer on pressing rollers is more convenient for maintenance. The technique also reduces the generation or expansion of micro cracks during welding. The roller surface hardening layer comes with high hardness (>HRC58), and high toughness as well. Due to these, the rollers come with service life over 8000 hours.

2. The utilization of aviation hydraulic technology ensures extremely reliable hydraulic system.

3. When the hydraulic system co-works with the automatic control system, the rolling machine is able to achieve functions such as, main drive motor load control, automatic fault diagnosis, as well as roller gap deviation control and adjustment.

4. The available control system adopts fuzzy control principle, and incorporates elements from world famous suppliers.

5. The powder separator for the roller mill has material scattering, classification, and drying functions. So, this range of cement grinding machine has low operational cost but high efficiency.

| Model | PFG120 ~50 | PFG120 ~60 | PFG 140 ~65 | PFG 140 ~70 | PFG 140~80 | PFG 140~120 | PFG 150 ~100 | PFG160 ~140 | PFG170 ~100 | PFG180 ~120 | PFG180 ~160 | PFG200 ~180 | |

| Diameter of roller (mm) | Φ1200 | Φ1200 | Φ1400 | Φ1400 | Φ1400 | Φ1400 | Φ1500 | Φ1600 | Φ1700 | Φ1800 | Φ1800 | Φ2000 | |

| Width of roller (mm) | 500 | 600 | 600 | 700 | 800 | 1200 | 1000 | 1400 | 1000 | 1200 | 1600 | 1800 | |

| Linear velocity of roller (m/s) | 1.47 | 1.47 | 1.48 | 1.48 | 1.48 | 1.52 | 1.56 | 1.57 | 1.65 | 1.75 | 1.74 | 1.83 | |

| Standard gap between rollers (mm) | 15~30 | 15~30 | 20~35 | 20~35 | 20~35 | 20~35 | 25~40 | 25~45 | 25~45 | 25~45 | 25~45 | 25~50 | |

| Maximum feed particle size (mm) | 55 | 55 | 60 | 60 | 60 | 60 | 60 | 60 | 65 | 65 | 65 | 80 | |

| Maximum feeding material temperature ( ℃ ) | ≤130 | ≤130 | ≤130 | ≤130 | ≤130 | ≤130 | ≤130 | ≤130 | ≤130 | ≤130 | ≤130 | ≤130 | |

| Pre-crushing capacity | Clinker (t/h) | 115~170 | 110 ~165 | 240 ~300 | 240 ~334 | 300~350 | 460~530 | 460 ~500 | 600 ~720 | 480 ~620 | 650~750 | 920~1120 | 1000~1250 |

| Raw mix (t/h) | 130~195 | 175~220 | 260 ~320 | 280 ~360 | 320 ~390 | 485 ~550 | 480 ~520 | 650~760 | 500~650 | 700~820 | 920~1150 | 1050~1280 | |

| Main motor | Model | Y315L-6 | Y355L-6 | YR50 01-8 | YR50 01-8 | YR560-8 | YR50 0 -4 | YR50 0 -4 | YRKK560 -4 | YR5004 -4 | YR560 -4 | YR6302-4 | YRKK7104-4 |

| Power (KW) | 250 × 2 | 280 × 2 | 500 × 2 | 500× 2 | 560× 2 | 800 × 2 | 710× 2 | 1120 × 2 | 900 × 2 | 1250 × 2 | 1600 × 2 | 2000 × 2 | |

| Rotary speed (r/min) | 960 | 960 | 740 | 740 | 750 | 1485 | 1485 | 1480 | 1485 | 1480 | 1490 | 1480 | |

| Voltage (V) | ~380V | ~380V | ~100 00V | ~100 00V | ~100 00V | ~100 00V | ~100 00V | ~10000V | ~10000V | ~10000V | ~10000V | ~10000V | |

| Model of main reducer | XGL38 | XGM38 | XGL 48 | XGL 48 | XGP 48B | RPG 28 | RPG 26 | GYM18 P2N | JGR2836 | GYM18 PZN | GYM2292N | GYM23PZN | |

| Total weight (t) | 65 | 68 | 105 | 110 | 115 | 156 | 150 | 210 | 195 | 225 | 250 | 290 | |

Related Names

Roller Mill | Industrial Grinder | Roll Press

Links:https://www.globefindpro.com/products/45301.html

-

1000mm Double-layer/Three-layer Co-extruded PE Cast Stretch Film Line

1000mm Double-layer/Three-layer Co-extruded PE Cast Stretch Film Line

-

Biodegradable PLA/PBAT Cling Film Extrusion Line

Biodegradable PLA/PBAT Cling Film Extrusion Line

-

Titanium Dioxide Rotary Kiln

Titanium Dioxide Rotary Kiln

-

Vertical Mill

Vertical Mill

-

Uniaxial Stretching Lithium-ion Battery Separator Film Extrusion Line

Uniaxial Stretching Lithium-ion Battery Separator Film Extrusion Line

-

Cement Packaging Machine

Cement Packaging Machine

-

Cling Film Edge Cutter

Cling Film Edge Cutter

-

Rainbow Film Extrusion Line

Rainbow Film Extrusion Line

-

Double Drum Rotary Dryer

Double Drum Rotary Dryer

-

3D PP Film and Sheet Extrusion Line

3D PP Film and Sheet Extrusion Line

-

Single Stage Hammer Crusher

Single Stage Hammer Crusher

-

Vertical Slag Mill

Vertical Slag Mill