2 Million Ton Cement Grinding Station

This range of cement grinding station is designed to offer annual production capacity of 2 million tons. It is a complete cement grinding, bulk transportation, and bag packaging line, mainly made up of a Φ4.2×13m open-circuit ball mill, 160-140 type rolling machine, and 1200V type powder separator.

Production Flow

1. Cement clinker unloading and storage

2. Gypsum unloading and conveying

3. Clinker conveying

4. Raw material batching station processing

5. Cement grinding and conveying

6. Pulverized coal storage and weight feeding

7. Cement storage and conveying

8. Cement packaging

9. Bulk cement transportation

10. Air compressor station

| Serial no. | Equipment function | Equipment name | Type / specifications | Quantity (set) | Annual utilization rate % | Remark |

| 1 | Gypsum crushing | Impact hammer crusher | Feeding material size: ≤ 600mm Discharging material size: ≤ 25mm (90%)Crushing capacity: 70t/h | 1 | 13.4 | |

| 2 | Cement grinding | Rolling machine | CLF160-140 Capacity: 380~500t/h Feeding material size: ≤ 70mm Discharging material size: 65%< 2mm; 20% < 0.09mm | 2 | 76.1% | |

| Cement mill | Φ4.2×13mCapacity: 150t/h Cement fineness: 340m2 /kg | 2 | 76.1% | For P.O42.5 cement grinding | ||

| 3 | Cement bulk transportation | Bulk truck | Capacity: 100t/h | 4 | 39.9% | Calculate by 70% |

| 4 | Cement packaging | Cement packaging machine | Capacity: 100t/h | 2 | 34.2% | Calculate by 30% |

Related Names

Clinker Grinding Unit | Cement Milling Process | Large Powder Grinder

Scan QR to Read

Links:https://www.globefindpro.com/products/45340.html

Links:https://www.globefindpro.com/products/45340.html

Recommended Products

-

Slag Grinding Mill

Slag Grinding Mill

-

Monocular Cooler

Monocular Cooler

-

Rubber Belt Conveyor

Rubber Belt Conveyor

-

Industrial Pump

Industrial Pump

-

SHFm Centrifugal Pump

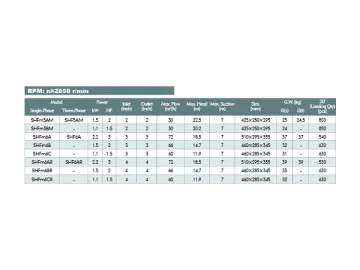

SHFm Centrifugal Pump

-

JGM767G High-dump Bucket Loader

JGM767G High-dump Bucket Loader

-

1.2 Million Ton Cement Grinding Machine

1.2 Million Ton Cement Grinding Machine

-

Hammer Crusher

Hammer Crusher

-

Tube Grinding Mill

Tube Grinding Mill

-

Automatic Liquid Resistance Starter

Automatic Liquid Resistance Starter

-

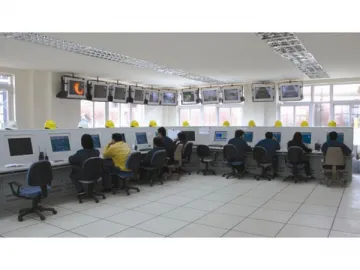

Cement Production Line Distributed Control System

Cement Production Line Distributed Control System

-

Vertical Coal Mill

Vertical Coal Mill