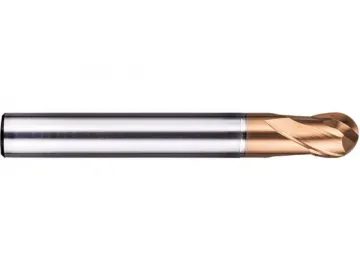

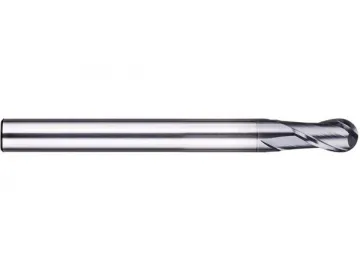

High Performance Solid Carbide End Mills, X Series

Wide Range of Applications

The variable helix is designed by taking both tool strength and chip space into consideration, suitable for high-efficiency machining applications where large cutting depth and width are needed;

Different Milling Operations

Face milling with small ap (depth of cut) and large ae (width of cut); Side milling with large ap (depth of cut) and small ae (width of cut); Shallow slotting (less than 0.5D);Superior Substrates and Coatings

Ultra-fine grained carbide substrates provide high wear resistance and hardness; Self-developed AlCrSiN coatings are applied along with Balzers latest KiLA furnace;Unique Cutting Edge Geometry

Variable pitch end mill utilizes unequal flute spacing, which enables vibrations to be suppressed;

| Item Code | Category | End Shape | Length Type | Number of Flutes | Flute Diameter | |

| High Performance End Mill | Square End | Regular | 3 | Ø3-Ø20 | ||

| High Performance End Mill (chambered) | Square End | Regular | 3 | Ø6-Ø16 | ||

| High Performance End Mill | Square End | Regular | 4 | Ø2-Ø20 | ||

| High Performance End Mill (chambered) | Square End | Regular | 4 | Ø3-Ø20 | ||

| High Performance End Mill (chambered) | Square End | Long Neck | 4 | Ø3-Ø20 | ||

| High Performance End Mill | Corner Radius | Regular | 4 | Ø3-Ø16 | ||

| High Performance End Mill | Ball Nose | Regular | 2 | Ø1-Ø12 | ||

| High Performance End Mill | Ball Nose | Long Shank | 2 | Ø4-Ø12 |

Scan QR to Read

Links:https://www.globefindpro.com/products/4542.html

Links:https://www.globefindpro.com/products/4542.html

Recommended Products

-

G-BN2 Solid Carbide End Mill for Graphite Machining - Ball Nose - 2 Flutes - Long Neck

G-BN2 Solid Carbide End Mill for Graphite Machining - Ball Nose - 2 Flutes - Long Neck

-

H-B2 Solid Carbide End Mill for Hardened Steel Machining - Ball Nose - 2 Flutes

H-B2 Solid Carbide End Mill for Hardened Steel Machining - Ball Nose - 2 Flutes

-

X-S4 High Performance Variable Helix End Mill - Square End - 4 Flutes

X-S4 High Performance Variable Helix End Mill - Square End - 4 Flutes

-

X-C4 High Performance Variable Helix End Mill - Square End - Chamfer - 4 Flutes

X-C4 High Performance Variable Helix End Mill - Square End - Chamfer - 4 Flutes

-

U-S3 General Purpose Solid Carbide End Mill - Square End - 3 Flutes

U-S3 General Purpose Solid Carbide End Mill - Square End - 3 Flutes

-

U-S4 General Purpose Solid Carbide End Mill - Square End - 4 Flutes

U-S4 General Purpose Solid Carbide End Mill - Square End - 4 Flutes

-

H-RN4 Solid Carbide End Mill for Hardened Steel Machining - Corner Radius - 4 Flutes - Long Neck

H-RN4 Solid Carbide End Mill for Hardened Steel Machining - Corner Radius - 4 Flutes - Long Neck

-

Solid Carbide End Mills for Hardened Steel Machining, H Series

Solid Carbide End Mills for Hardened Steel Machining, H Series

-

G-S3 Solid Carbide End Mill for Graphite Machining - Square End - 3 Flutes

G-S3 Solid Carbide End Mill for Graphite Machining - Square End - 3 Flutes

-

X-BH2 High Performance Solid Carbide End Mill - Ball Nose - 2 Flutes

X-BH2 High Performance Solid Carbide End Mill - Ball Nose - 2 Flutes

-

S-R4/RS4 Solid Carbide End Mill for Stainless Steel Machining - Corner Radius - 4 Flutes - Short Flute

S-R4/RS4 Solid Carbide End Mill for Stainless Steel Machining - Corner Radius - 4 Flutes - Short Flute

-

S-B2 Solid Carbide End Mill for Stainless Steel Machining - Ball Nose - 2 Flutes

S-B2 Solid Carbide End Mill for Stainless Steel Machining - Ball Nose - 2 Flutes