Electric Curing Oven

This electric curing oven is opened through single leaf head. It consists of the air supply and return system, heating system and other parts.

Air Supply and Return System

1. In the cycling way of supplying air at the bottom and getting the air back on the upper, this system can balance the hot air.

2. It also uses the air deflector and bottom plate with punched holes to keep even temperature.

3. The system is equipped with a circulating fan, whose power is 1.5kw.

Heating system

The heating system is assembled with belt radiating fin, stainless steel electric heating pipe, circulating fan, automatic temperature control probe and other parts. After the electric heating pipe is energized in the heating room, the heat is transferred directly to the inside of drying tunnel by circulating fan. As the fan cycles constantly, the temperature inside the oven rises continuously to the given value and is well distributed.

The adjustment on automatically controlled temperature in the drying tunnel is displayed on the digital screen. Moreover, the burned waste air will be eliminated through exhaust pipe. When the temperature rises to the upper limit, the insulation kit will be closed automatically. At the lower limit, it will be started again. The circulating fan is made of special materials for insulation and its extended shaft is efficient to protect the electric motor.

Technical Specifications

| Inner dimension | L1500mm×W1500mm×H2000mm |

| Material for inner wall | 1.0mm thick stainless steel plate |

| Material for outer wall | 1.0mm thick Warren contour plate |

| Insulating layer | 150mm thick adiabatic rock wool |

| Rail car | Welded by 4# angle bar |

| Power of fan | 1.5kw |

| Heating power | 40kw |

Related Names

Powder Coating Oven Manufacturer | Vehicle Part Painting Solution | Industrial Painting Accessory

Links:https://www.globefindpro.com/products/45554.html

-

Spray Cabinet (6 pcs Filter)

Spray Cabinet (6 pcs Filter)

-

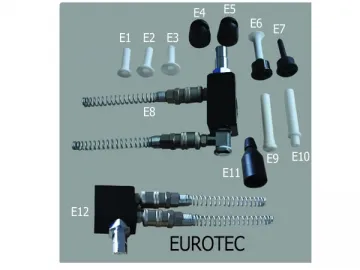

EUROTEC Powder Gun Parts

EUROTEC Powder Gun Parts

-

Curing Oven

Curing Oven

-

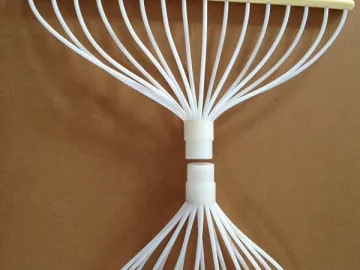

Tribomatic Automatic Powder Gun Spray Heads

Tribomatic Automatic Powder Gun Spray Heads

-

COLO-G Powder Coating Equipment

COLO-G Powder Coating Equipment

-

Powder Coating Oven

Powder Coating Oven

-

COLO-N Powder Coating Parts

COLO-N Powder Coating Parts

-

Extend Nozzle / Extended Spray Nozzle

Extend Nozzle / Extended Spray Nozzle

-

Lab Powder Curing Oven

Lab Powder Curing Oven

-

Polyester-Epoxy Powder Coating

Polyester-Epoxy Powder Coating

-

COLO-N Powder Gun Parts

COLO-N Powder Gun Parts

-

Insulation Products

Insulation Products