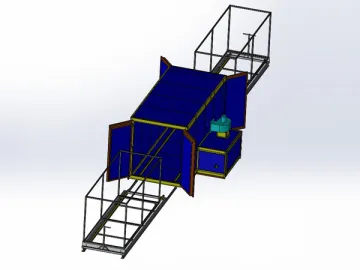

Curing Oven

Equipment Configuration and Instructions

1. A curing oven with single head for opening the door

The inner size is L1900×W800×H1000mm and the inner wall is made of hot rolled plate that is 1.0mm thick. The outer wall of the product adopts the 1.0mm thick Warren contour plate. With adiabatic rock wool, the insulating layer is about 100mm thick.

2. Air supply and return system

a. This system supplies the air from the bottom and gets the air back at the top part to balance the hot air.

b. The air deflector for guiding wind and the bottom plate is punched with holes to ensure the even temperature.

c. This curing oven is also equipped with a specially made thermal cycling fan with extended shaft, whose power is 1.5kw.

3. Heating system with 6kw power

Its heating system comprises of belt radiating fin, electric heating pipe, circulating fan, automated temperature control probe and other parts. After being energized in the heating chamber, the electric heating pipe sends the heat to the inner part of the drying tunnel directly through circulating fan, which rotates to increase the temperature inside the curing oven to the setting temperature constantly in good distribution.

The product controls the temperature automatically and the adjustment is showed by digital display. The waste air is emitted via the exhaust pipe. As the temperature reaches the upper limit, the insulation kit exerts automated close and will be started automatically when the temperature arrives at the lower limit. The circulating fan adopts special materials for insulation to protect the electric motor effectively. In addition, we also use the Delixi and Chint automatic control case appliance.

Design Considerations

| No. | Item | Parameters |

| 1 | Name of work piece | Wheel hub |

| 2 | Max. size of work piece | Diameter: 500mm, thickness: 20mm |

| 3 | Production capacity | Fixed quotas of the curing oven |

| 4 | Coating method | Manual |

| 5 | Heating method | Electric heating |

Note: Coating process: Hanging the work piece on the powder spray worktable (pretreatment for qualified work piece) --- manual spraying ---- hanging the work piece on the curing bracket ---- pushing it into the oven for curing at 180 to 200ºC --- drawing out the curing bracket and taking the work piece away

Related Names

Powder Curing Furnace Supplier | Workpiece Surface Treatment | Industrial Oven

Links:https://www.globefindpro.com/products/45557.html

-

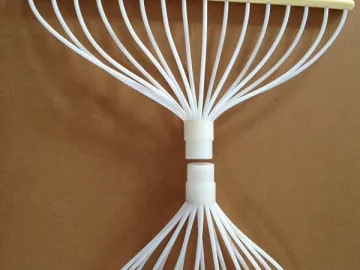

Tribomatic Automatic Powder Gun Spray Heads

Tribomatic Automatic Powder Gun Spray Heads

-

COLO-G Powder Coating Equipment

COLO-G Powder Coating Equipment

-

Powder Coating Oven

Powder Coating Oven

-

Tribomatic II Automatic Powder Spray Gun

Tribomatic II Automatic Powder Spray Gun

-

Metal Oxide Surge Arrester

Metal Oxide Surge Arrester

-

Powder Coating Oven with Track Trolley

Powder Coating Oven with Track Trolley

-

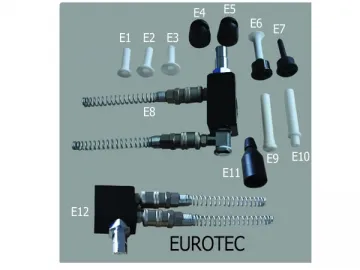

EUROTEC Powder Gun Parts

EUROTEC Powder Gun Parts

-

Spray Cabinet (6 pcs Filter)

Spray Cabinet (6 pcs Filter)

-

Electric Curing Oven

Electric Curing Oven

-

COLO-N Powder Coating Parts

COLO-N Powder Coating Parts

-

Extend Nozzle / Extended Spray Nozzle

Extend Nozzle / Extended Spray Nozzle

-

Lab Powder Curing Oven

Lab Powder Curing Oven