Metal Oxide Surge Arrester

The metal oxide surge arrester is used to protect the 110kV gas insulated switchgear from the damage resulting from atmosphere and overvoltage. According to different installation methods, the lightning arrester can be divided into the one with the line outlet from the top and the one with the line outlet from the side.

Product Model

Y10WF-100/260S, Y10WF-102/266S, Y10WF-108/281S

Working Conditions

1. Installation place: indoor or outdoor;

2. Ambient temperature: -30℃~ 40℃;

3. Solar radiation: the strongest radiation limit is 1.1 kW/m2;

4. AC frequency: 48Hz~62Hz;

5. The long-term voltage applied to the terminals in the metal oxide surge arrester shouldn't exceed its continuous operating voltage;

6. Our surge protection device can work in areas where the seismic intensity is no more than 7 degree.

7. Other conditions should be consistent with related requirements of GB 7674.

Main Technical Parameters

The metal oxide surge arrester is supposed to completely meet the requirements of GB11032-2010 and IEC 60099-4 (2006). The main technical parameters are shown in table 1.

Table 1

| Nominal voltage of the system kV (RMS) | Rated voltage kV (RMS) | Continuous-running voltage kV (RMS) | Nominal discharge current kA | Lightning impulse residual voltage ≤kV (peak) | Power frequency (resistive 1mA) reference voltage ≥kV(peak/√2) | 1mA DC reference voltage ≥kV | Persistent current under Uc ≤μA (peak) |

| 110 | 100 | 78 | 10 | 260 | 100 | 145 | 200 |

| 110 | 102 | 79.6 | 10 | 266 | 102 | 148 | 200 |

| 110 | 108 | 84 | 10 | 281 | 108 | 157 | 200 |

Structural Characteristics and Working Principle

1. The metal oxide surge arrester's core body adopts a circular metal oxide varistor which has an excellent nonlinear current-voltage characteristic. Through the single-column structure fixed via an insulating support base and the external use of explosion-proof tube protection, the components of the surge arrester are fastened tightly together.

The core body is mounted with a shielding case for equalizing internal potential distribution and electric field distribution, and the entire assembly is encapsulated in a shell. After vacuumed, the shell is filled with SF6 gas to ensure high insulation strength. With protection from the metal shell, the performance of the surge arrester is not influenced by the external environment and thus ensures fine electrical properties.

Thanks to the reduced voltage peak between the arrester terminals at steep impulse current conditions, the overvoltage protection device offers larger range of protection for gas insulated switchgears with flat volt-second characteristic curve.

2. With excellent nonlinear current-voltage characteristics, the metal oxide varistor exhibits low resistance when over-voltage arises in the power grid system, so as to reduce the system voltage to the limited range to protect the power transmission and transformation equipment. When the system operates under normal conditions, the nonlinear metal oxide varistor will deliver high resistance, and the current passing through the surge arrester is just at a microampere level, thus the normal operation of the power grid system is assured.

3. The external metallic shell delivers enough strength against the internal pressure during an accident. The metal shell features high yield strength and offers a fine sealing performance. We can also install explosion-proof device according to the GIS or users' requirements. When the internal pressure increases to a specified value, the explosion-proof device is activated to release internal pressure to avoid accident or corresponding impacts.

User Instructions

1. During transport, storage and installation, the metal oxide surge arrester must be placed upright. Avoid external impacts or collisions to protect inner components. If any similar phenomenon is detected, carefully check the device to avoid any damage before using it. When any damage happens, return the product to the factory if necessary.

2. When delivering the lightning arrester in a vehicle, the vehicle acceleration shouldn't be more than 3g. The speed shouldn't exceed 30km/h in case of poor road conditions.

3. In lifting the metal oxide surge arrester, the rope should hang on the hook so as not to damage the surface. Keep the product upright when lifting and be gentle when putting it in an expected place.

4. The surge protector should be kept in a dry, clean workshop free from corrosive gases or liquids.

5. For normal use, the metal oxide surge arrester should be filled with 0.4MPa (20 ℃) SF6 gas and the maximum density of the SF6 gas during operation should be no more than 0.5MPa and the minimum should be no less than 0.35MPa.

6. When leaving factory and in transportation, the product should be filled with 0.02MPa-0.05MPa (gauge pressure) SF6 gas. To guarantee good sealing, the product should not be un-sealed without the factory's permission.

7. When installing the pneumatic pipeline and the density monitor, do not open the valve unless the pneumatic pipeline and the density monitor have been installed and tested.

8. To supplement SF6 gas for the metal oxide surge arrester, the indexes of the SF6 gas should meet the requirements in GB12022.

Links:https://www.globefindpro.com/products/45562.html

-

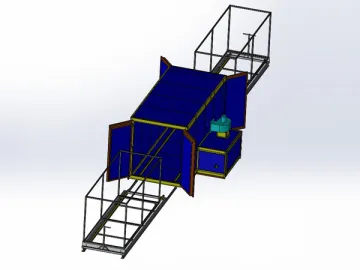

Powder Coating Oven with Track Trolley

Powder Coating Oven with Track Trolley

-

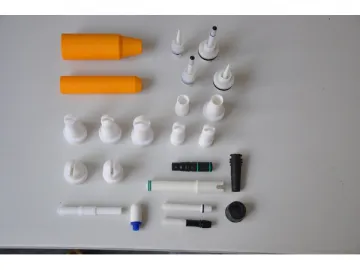

Powder Spray Gun Parts

Powder Spray Gun Parts

-

Pure Epoxy Powder Coating

Pure Epoxy Powder Coating

-

Powder Coating System, CL-151S-F

Powder Coating System, CL-151S-F

-

Fuel Oil Powder Coating Oven

Fuel Oil Powder Coating Oven

-

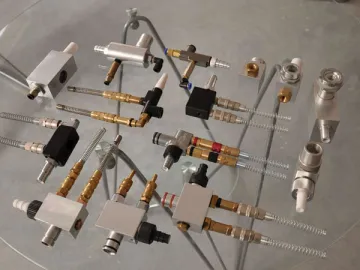

Powder Injector

Powder Injector

-

Tribomatic II Automatic Powder Spray Gun

Tribomatic II Automatic Powder Spray Gun

-

Powder Coating Oven

Powder Coating Oven

-

COLO-G Powder Coating Equipment

COLO-G Powder Coating Equipment

-

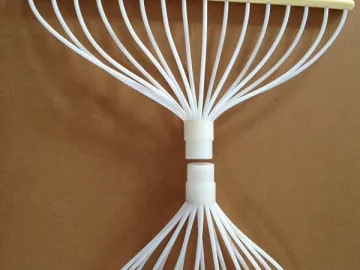

Tribomatic Automatic Powder Gun Spray Heads

Tribomatic Automatic Powder Gun Spray Heads

-

Curing Oven

Curing Oven

-

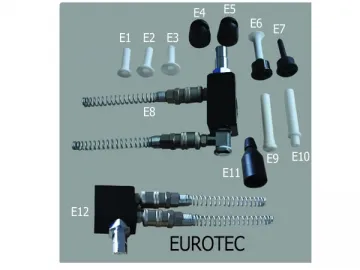

EUROTEC Powder Gun Parts

EUROTEC Powder Gun Parts