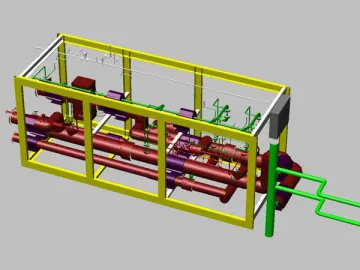

Skid Mounted Metering System

The skid mounted metering system is an overall solution for the loading and unloading of low-temperature liquefied natural gas. It is installed inside a 2.5m×2.2m×5.5m supporting frame. This frame incorporates the main liquid pipeline, gas pipeline, nitrogen purge line, waste gas burning pipeline, residue recycling line, and the compressed instrument air line. The flow meters, flow control valve, emergency shut-off valve, temperature transmitter, pressure transmitter, pressure relief valve and a large number of process control valves are combined in the entire pipeline.

A vaporization device is specially designed for the unloading operation. This device takes the liquid LNG out from the liquid pipeline and makes it vaporized to provide the unloading system with high-pressure LNG, thus providing continuous power for the unloading system.

All these instruments are controlled by a PLG. According to the logical order of loading and unloading, the central processor will perform operations step by step according to the program.

The entire system is compact, logically clear, space-saving, safe and reliable. It is widely used in refinery and chemical factories.

Main Features of the Product

1. This metering system adopts China's low-temperature aerospace technology.

2. It can be used for loading and unloading in two sides.

3. PG, TIT and PIT instruments adopt centralized display.

4. The swivel joint utilizes the dynamic sealing technology, which completely avoid the deformation of the sealing surface.

5. All key components are imported.

Control System

The quantitative loading control system is compact in structure. The whole process from billing, loading, delivering, accounting to reporting is completed under system management. The automatic alarm system can effectively prevent accidents happening and avoid artificial cheating in operation, thus eliminating management loopholes to the greatest extent.

Main Functions of PLC

1. Monitoring LNG handling flow

2. System flow control

3. System pressure, temperature measurement and control

4. Dynamically display the handling process, process parameters and equipment operating status

5. Remotely control the valves, pumps and other equipment

6. Set and modify the control parameters on line

7. Alarm and record the abnormal conditions

8. Communicate with the existing systems through communication protocols, facilitating the unified management of all production information.

Related Names

Fluid Metering and Control Device | Top and Bottom Loading System | Land Loading Management

Links:https://www.globefindpro.com/products/45638.html

-

Vertical High-speed Centrifugal Pumps

Vertical High-speed Centrifugal Pumps

-

Reaction Furnace

Reaction Furnace

-

(QC/DC) Hydraulic Quick Connect/Disconnect Coupler

(QC/DC) Hydraulic Quick Connect/Disconnect Coupler

-

Disc Valve

Disc Valve

-

Changeover Valve/Switching Valve

Changeover Valve/Switching Valve

-

High-pressure Abrasion-proof Pump

High-pressure Abrasion-proof Pump

-

Safety Valve with Jacket

Safety Valve with Jacket

-

RC Single Pipeline Marine Loading Arm

RC Single Pipeline Marine Loading Arm

-

Automatic Return Valve

Automatic Return Valve

-

Cryogenic Marine Loading Arm

Cryogenic Marine Loading Arm

-

COLO-2000D Automatic Reciprocator

COLO-2000D Automatic Reciprocator

-

Intelligent Double System Powder Coating Machine

Intelligent Double System Powder Coating Machine