39/41 Punch Sets Rotary Tablet Press

This series of tablet press comes with 39 or 41 pairs of punches. It is a double-compression, automatic-rotation mechanical device that allows continuous operation. That means the tablet can be compressed twice and the punches rotate automatically.

With this machine, granulated feedstock is compacted into various shapes, round or irregularly shaped. Words are carved on the tablet and two different colors can be applied to one tablet, too. This tablet press is mainly employed by drug manufacturers while many chemical, food, and electronic enterprises use it as well.

Features

1. The machine enclosure is made of stainless steel. This material is also used in constructing the working table inside the enclosure, to give a smooth, bright surface and keep it from contamination. The whole machine is manufactured to the GMP standard.

2. The work platform is actually surrounded on its four sides by organic glass. Via this sight glass, operators can observe the condition of tablet being compressed. The glasses on both sides can fully opened to allow easy cleaning and maintenance.

3. All the controllers and operating parts are properly arranged on the machine.

4. A variable-frequency motor is used to regulate the speed of various electrical and pneumatic devices. With this motor, speed control can be simple, safe, reliable and accurate.

5. The tablet press is available with an overload protector, which can automatically shut off the machine in the event of pressure overload.

6. This machine incorporates the functionality of mechanical device and electrical device in one.

7. Our company is the first to pioneer the use of oil bath lubrication system and dust-proof technology on the compression machine.

8. The transmission system hermetically sealed within the lower part of machine and inside the oil tank. This means the transmission parts can be totally submerged in a pool of oil for quick heat dissipation and high wear resistance. The transmission system is entirely isolated from other operating parts. Hence, users need not worry about main machine parts being contaminated by oil.

9. A dust collector is fitted to compression chamber to collect the powder released from the compression process.

10. Consumable parts on this tablet press including upper rail, stock feeder, hopper, worm drive, and powder metering device can fit into the ZP33 series machine. They are designed to specifications to ensure interchangeability.

11. Punches on this machine can also fit into the ZP19, ZP33, ZP35, and ZP37 series.

Technical Specification

| Model Number | ZP39D | ZP41D |

| No. of Punches | 39pairs | 41pairs |

| Maximum Compression Pressure | 80KN | 60KN |

| Maximum Compression Diameter | 13mm | 15mm |

| Maximum Filling Depth | 15mm | 15mm |

| Maximum Tablet Thickness | 6mm | 6mm |

| Rotation Speed of the Rotating Turret | 3-35rounds/minute | 3-32 rounds/minute |

| Maximum Production Capacity | 157440tablets/hour | 163800tablets/hour |

| Power Supply | 380/50 V/Hz | 380/50 V/Hz |

| Power of Main Motor | 4Kw | 4Kw |

| Dimension | 1240×980×1650mm | 1240×980×1650mm |

| Net Weight | 1850kg | 1850kg |

Related Names

Tablet Making Equipment | Pharmaceutical Machinery | Tablet Production Machine

Links:https://www.globefindpro.com/products/45797.html

-

Back Sealing Granule Packing Machine

Back Sealing Granule Packing Machine

-

19/21 Punch Sets Rotary Tablet Press

19/21 Punch Sets Rotary Tablet Press

-

PLC Granule Packing Machine

PLC Granule Packing Machine

-

Back Seal Powder Packing Machine

Back Seal Powder Packing Machine

-

Back Sealing Liquid / Paste Packing Machine

Back Sealing Liquid / Paste Packing Machine

-

Two Pack Liquid / Paste Packing Machine

Two Pack Liquid / Paste Packing Machine

-

3-Side Sealing Granule Packing Machine

3-Side Sealing Granule Packing Machine

-

Automatic Pneumatic Liquid / Paste Packing Machine

Automatic Pneumatic Liquid / Paste Packing Machine

-

Two Pack Granule Packaging Machine

Two Pack Granule Packaging Machine

-

3-Side / 4-Side Seal Granule Packing Machine

3-Side / 4-Side Seal Granule Packing Machine

-

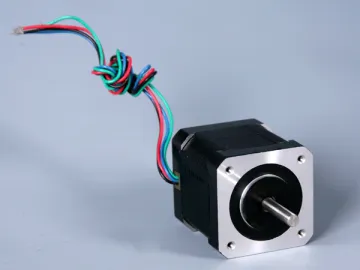

1.8 Degree Size 42mm 2-Phase High Torque Hybrid Stepper Motor

1.8 Degree Size 42mm 2-Phase High Torque Hybrid Stepper Motor

-

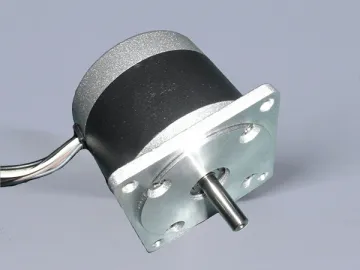

57mm High Torque Brushless Motor

57mm High Torque Brushless Motor