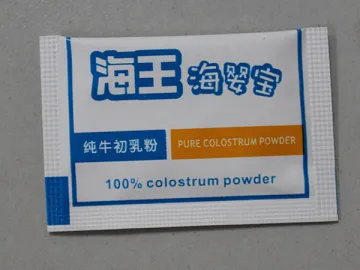

3-Side Seal Powder Packing Machine

The 3-side seal powder packing machine is very effective with the task of packing powders with a total weight below 2g. During the sealing process, an L-shaped heat-sealing bar clamps onto the side edge and bottom edge of the bag to create two seals by melting the edge. Then the powdered material is dispensed out from the hopper into the bag. After the gross weight of the powder-filled bag is reached, filling stops and the top edge of the bag is sealed. When the final sealing is done, a scissor-like cutter is used to cut off the bag.

This piece of equipment is a perfect fit for packaging single product rather than mixed materials. It is specially intended for constructing bags less than 30mm in width and below 50mm in length, and filling in them with powdery materials characterized by low flowability. For customers who want to pack their chemicals or seasonings into a small bag, this packing machine just provides an ideal choice.

Parameters

| Specification Model Number | DCF-200 |

| Plastic Film Width | Maximum 200mm |

| Measuring Method | Metering Screw Feeder |

| Range of Measurement | 0-100ml(0-5ml,5-20ml,20-50ml,30-100ml) Each packing machine is paired with a complete set of metering screw feeder. Different screws will be used for measuring volumes that fall into different measurement ranges. |

| Bag Width | 30-100mm |

| Bag Length | 30-120mm |

| Sealing Types | Three-Side Seal |

| Packaging Speed | 40-60packs/minute |

| Power Supply | 220V,1.1KW |

| Dimension (L×W×H) | 625×751×1558mm |

| Weight | 200kg |

Related Names

Dry Powder Filling Machine | Plastic Bag Seal Equipment | Sachet Sealing Machine

Links:https://www.globefindpro.com/products/45820.html

-

Ketchup Packaging Machine

Ketchup Packaging Machine

-

5/7 Punch Sets Rotary Tablet Press

5/7 Punch Sets Rotary Tablet Press

-

Powder Metering and Semi-Automatic Filling Machine

Powder Metering and Semi-Automatic Filling Machine

-

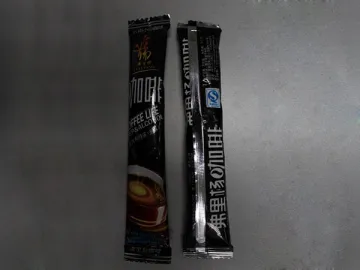

Coffee Packaging Machine

Coffee Packaging Machine

-

DCCK-400/500/600 Weighing Packing System

DCCK-400/500/600 Weighing Packing System

-

Hair Conditioner Packing Machine

Hair Conditioner Packing Machine

-

Three Pack Liquid / Paste Packing Machine

Three Pack Liquid / Paste Packing Machine

-

Three Pack Granule Packaging Machine

Three Pack Granule Packaging Machine

-

Tetrahedron Bag Granule Packaging Machine

Tetrahedron Bag Granule Packaging Machine

-

V-Shaped Blender

V-Shaped Blender

-

Semi-automatic Powder Filling Machine

Semi-automatic Powder Filling Machine

-

U Trough Mixer

U Trough Mixer