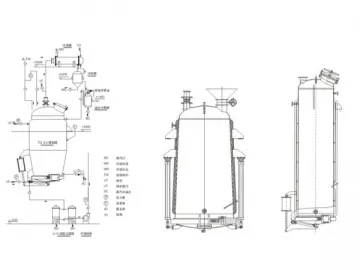

Top Manway Fermentation Tank

Overall View

| Structural Chart of Top Manway Fermentation Tank | Partial View |

Our top manway fermentation tank acts as an essential device in the fermentation chamber of the brewery. It is a cylinder with conical bottom, which is perfect for small and medium-sized beer companies.

Working Principle

1. The cold wort will be delivered to our top manway fermentation tank from its bottom, after the coagulum is filtered. Then, yeast is required for fermentation. For a smooth fermentation process, the heat generated during fermentation will be taken away by the cooling medium inside the jacket.

2. During fermentation, the ventilatory capacity, aging time, fermentation time, the amount of yeast, and the temperature of the wort are based on the fermentation technology. The operating temperature inside our fermenter varies from -1 degrees Celsius to 15 degrees Celsius. The working pressure on top of the fermenter reaches 0.09MPa.

3. Once the fermentation broth meets the technical needs, our product will discharge the precipitated yeast and then the fermentation broth. After the liquid is emptied, both accessories and the inner wall of our equipment will be completely cleaned for the next fermentation.

4. Dilute alcohol is used as the cooling medium, for the purpose of heat exchange within the dimple jacket.

Technical Specifications

| No. | Item | Internal Tank | Internal Jacket |

| 1 | Working Pressure (MPa) | 0.09 | 0.4 |

| 2 | Design Pressure (MPa) | 0.09 | 0.4 |

| 3 | Operating Temperature (℃) | -1~15 | -4 |

| 4 | Design Temperature (℃) | -1 | -4 |

| 5 | Medium | Fermentation Broth | Glycol |

| 6 | Range of Working Volume (L) | 500L~25000L | |

| 9 | Material of Pressure Parts | 304 | |

| 10 | Corrosion Allowance (mm) | 0 | |

| 11 | Welded Joint Efficiency | 0.85 (Double-sided Welding) | |

Structure Declaration

The conical fermenter with plug welded dimple jacket is an airtight, vertical cylinder with conical bottom.

Structural Features

1. Fermenter Bottom

The bottom of our top manway fermentation tank is a toriconical head with cone angle of 60°. It is made for yeast sedimentation and also gives convenience for discharging yeast.

2. Main Body

The main body of this fermenter is cylindrical and pretty high. It enables the fermentation broth to form natural convection on a vertical surface, thus making the temperature of the fermentation broth be well controlled.

3. Jacket Structure

The jacket of our top manway fermentation tank falls into multiple segments for cooling. The first and second segments of the main body put to use the plug-welded dimple jacket. They are arranged in line with the heat transfer area and technical needs. One segment of the conical bottom also utilizes the plug-welded dimple jacket. It is usually arranged in the largest area.

During fermentation, the jacket can partially or wholly get in touch with the cooling medium based on the temperature variation inside our machine. Hence, it can cater for the technical needs for fermentation temperature.

4. Cleaning System

The clean-in-place (CIP) system is mounted on top of our fermenter. It allows the wash water and CO2 gas to share the same pipe and enter the fermenter. Furthermore, it can well guarantee the pressure and flow velocity of both wash water and CO2 when entering the tank.

5. Dosing System

Our top manway fermentation tank is assembled with the inlet for dosing both hops and CO2, for being accustomed to distinct technical needs.

6. Accessories

On top of our fermenter, there are the manway and the safety valve. When the pressure inside the fermenter exceeds the working pressure and reaches 0.095MPa, the safety valve will be automatically opened for gas evacuation and pressure reduction. After that, the safety valve will be automatically closed.

When the pressure inside the fermenter is reduced to -0.002MPa, the air must be poured into our tank to prevent the vacuum valve from being automatically opened. Then, the differential pressure in and out of the tank can be balanced, and the equipment will not be deflated or damaged.

All of our accessories are connected by tri-clamp. They include the thermometer, pressure gauge, sampling valve, racking arm, and the butterfly valve.

7. Monitoring System

a. This top manway fermentation tank is equipped with a connector that can measure and control the temperature of the fermentation broth inside our fermenter at any time.

b. Our fermenter is also mounted with a thermometer, which gives convenience for in-situ observation.

c. Moreover, this product is designed with the sampling valve at the position where the operation is made convenient. This valve is able to sample and analyze the fermentation broth inside the fermenter at regular intervals.

Remarks: The top manway fermentation tank is quite popular in UK and Spain. Its price is cheaper than that of the side manway fermenter.

| Safety Valve | Semi-finished Product | Butterfly Valve | Dimple Jacket |

| Welded Orifice | Fittings | Sampling Valve | Tee Joint |

| Elbow Bend | Thermometer | Thermometer Casing | Pressure Gauge |

Related Names

Beer Fermenting Container | Stainless Steel Fermentation Vessel | All Grain Brewing Equipment

Links:https://www.globefindpro.com/products/45896.html

-

Multi-functional Extraction Tank

Multi-functional Extraction Tank

-

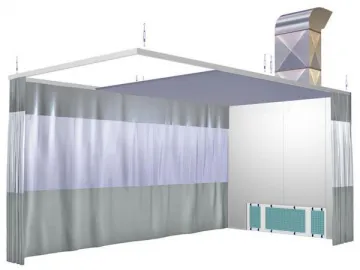

BZB-FB-1800 18m Bus Spray Booth

BZB-FB-1800 18m Bus Spray Booth

-

Butter Churn

Butter Churn

-

BZB-FB-900 9m Bus Spray Booth

BZB-FB-900 9m Bus Spray Booth

-

UHT Pasteurizer

UHT Pasteurizer

-

Gas Fired Jacketed Kettle

Gas Fired Jacketed Kettle

-

Roller Conveyor Steel Square and Bar Shot Blast Machines

Roller Conveyor Steel Square and Bar Shot Blast Machines

-

Hot Water Tank

Hot Water Tank

-

6100 Prep Station

6100 Prep Station

-

15GN-7M Belt Conveyor Shot Blasting Machine

15GN-7M Belt Conveyor Shot Blasting Machine

-

BZB-FB-1200 12m Bus Spray Booth

BZB-FB-1200 12m Bus Spray Booth

-

Vacuum Emulsion Mixer

Vacuum Emulsion Mixer