High Shear Mixing Tank

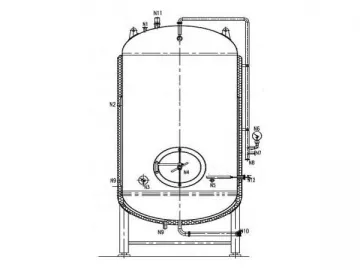

High Shear Tank with Steam-Heated Bottom

This high shear mixing tank integrates such functions as mixing, emulsifying, homogenizing, dissolving, pulverizing, and more. Its production capacity ranges from 100L to 25,000L. Our product is made entirely from stainless steel. It has passed CE certifications, and its production process complies with the ISO standards. All parts touching with feed materials put to use either the hygienic grade stainless steel 304 or stainless steel 316L on request.

While the high-speed emulsifying head is working, the material in the center of the rotor is fast thrown to the stator. Then, the material will be subjected to such processes as high shear, impact, and crushing process between the rotor and the stator, to reach the goal of emulsification.

Applications

1. In food industry, our high shear mixing tank can be used for food coloring, chocolate coating, the filling foods, syrup, condiments, and various types of additives, among others.

2. In pharmaceutical industry, it is applicable for ointments, lotions, creams, diversified vitamins, and more.

3. In daily chemical industry, this product plays a role in producing shampoo, detergents, creams, ointments, paraffin wax solution, hair dyes, and other goods.

4. In adhesive industry, it can be found in the manufacturing of rubber solution, polyester sulfide, silicone, hot melt adhesive, polyurethane, and some others.

Structure

The structure of our high shear mixing tank is characterized by extremely humanized design and strong maneuverability. This product can be single-layered, or designed with diversified jackets, such as the dimple jacket, coiled-tube jacket, and the overall jacket. Its insulating layer is formed by PU foam for achieving satisfactory thermal-insulation effect.

For better guaranteeing a hygienic design without dead corners, the internal wall of the container utilizes the circular-arc transition. The internal tank is mirror-polished, and its roughness average is at most 0.4. The outer surface of the vessel can optionally receive a brushed finish, satin finish, and 2B finish. Furthermore, our product can be designed and manufactured according to customer requirements.

Heating Methods

This high shear mixing tank adopts electrical heating or steam heating method to heat the materials. The electrical heating method is suitable for the tank with its working volume of less than 2,500L. Customers are required to inform us of the steam working pressure inside the jacket, so as to select an appropriate thickness of stainless steel sheets.

Agitation Pattern

The mixer motor is introduced from optional brands, such as ABB, SEW, Siemens, and the ordinary domestic motor. Its installation method can be either top mounting type or bottom mounting type. The speed of agitator can be either fixed or adjusted by assembling a frequency converter. A control cabinet can be adopted to control the stirring rate if required.

Fittings

Our high shear mixing tank can be configured with such fittings as the quick-opening manhole, sight glass, cleaning ball, thermometer, pressure gauge, the material-outlet matching butterfly valve, the electronic weighing system, as well as the liquid level gauge and liquid level control system. The last two fittings are installed on basis of customer requirements.

Related Names

Emulsifying Tank | High Shear Emulsifier | Powder Blending Equipment

Links:https://www.globefindpro.com/products/45923.html

-

Brite Tank

Brite Tank

-

Vacuum Pressure Relief Concentration Tank

Vacuum Pressure Relief Concentration Tank

-

Stainless Steel 135 Degree Elbow

Stainless Steel 135 Degree Elbow

-

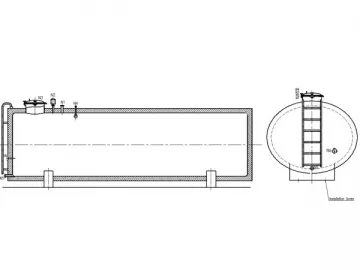

Milk Transfer Tank

Milk Transfer Tank

-

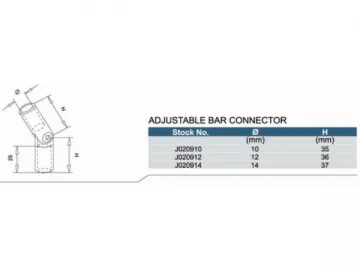

Stainless Steel Adjustable Upright Tube-Bar Connector

Stainless Steel Adjustable Upright Tube-Bar Connector

-

Stainless Steel Swageless Terminal

Stainless Steel Swageless Terminal

-

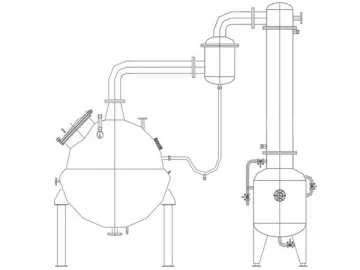

Ball Shaped Concentration Tank

Ball Shaped Concentration Tank

-

Milk Bucket

Milk Bucket

-

Steam Heated Mixing Tank

Steam Heated Mixing Tank

-

Plate UHT Pasteurizer

Plate UHT Pasteurizer

-

Electrical Heating Jacketed Kettle

Electrical Heating Jacketed Kettle

-

Falling Film Evaporator

Falling Film Evaporator