Plate Heat Exchanger

Our plate heat exchanger is composed of numerous plates, which are pressed by utilizing the metal sheets of various corrugated shapes. The fluid media flow in alternate channels is formed by these plate corrugations, and separated by the plate material and the sealing gaskets. Through these plates, it can achieve the goal of heat transfer.

Generally, the corrugated plates of our plate heat exchanger can be divided into straight type and herringbone type. They offer three main functions listed as follows.

1. The effective heat transfer area is increased.

2. After the plates are assembled, the multi-point contacts of two corrugated plates can enhance the rigidity and hardness of the plates, so as to withstand the large pressure difference between two channels.

3. The medium can be easily in a turbulent flow within the channel, which can slow down the formation speed of fouling.

| Material Name | Thickness | Component | Application |

| Stainless Steel | 0.7~1.0 | OCr18Ni9(SUS304) OOCr19Ni10(SUS304L) OCri17Ni12MO(SUS316) OCr17Ni14MO (SUS316L) | It is ideal for the severely corrosive conditions from acids and bases. It is not suitable for chloride-containing working conditions. |

| Industrial Pure Titanium | 0.6~1.0 | TAE | It is applicable for alkali making, salt manufacturing, the low-temperature refrigeration of seawater, and the severely corrosive working conditions with chloride ions. |

| Stainless Steel with Super Low Carbon Content | 0.6~1.0 | OOCr18 Vi14Mo2Cu2 | It can be applied in organic solvents, intergranular corrosion, and chloride corrosion. |

List of Sealing Gaskets

| Name | Corrosion Resistance and The Conditions of Use | Operating Temperature |

| NBR Mat | Oil proof, Suitable for general corrosion conditions | -20~110℃ |

| Neoprene Mat | Oil proof, Suitable for general corrosion conditions | -20~110℃ |

| EPDM Mat | Resistance to acids, alkalis, and salts Ideal for the severely corrosive conditions from chlorides, organic solvents, and more | -50~150℃ |

| Silicone Rubber Mat | Suitable for high-temperature working environments | -65~230℃ |

| Special Type Synthetic Rubber Mat | Desirable for high-temperature working environments | -20~300℃ |

| Food Grade Rubber Mat | Proper for a variety of food-medium conditions | -20~150℃ |

Path Combination

Our plate heat exchanger is designed with diversified patterns of path combination, which can be realized by adoption of different assembly methods. The path combination can be categorized into single path, multiple paths, and a mixed path. It ought to be selected on basis of technical requirements.

With its temperature difference 1.8 times larger than the logarithmic mean temperature difference, the medium should utilize a suitable value of flow velocity from 0.3m/s to 0.5m/s between multiple-path plates. It is advisable to adopt two paths or multiple paths when the flow velocity is too low.

Parallel Connection Combination Chart

Series-Parallel Connection Combination Chart

This plate heat exchanger can be divided into BR type and BRB type. With distinct specifications, it can be expressed as follows: B R 0.2 1.0 15 N VII

1. The letter 'B' represents the plate heat exchanger.

2. The letter 'R' means that the plate corrugation is herringbone with unequal cross-sectional area.

3. The digit represents that the nominal heat transfer area of each plate is 0.2m2.

4. The number means that the design pressure is 1.0MPa.

5. The number shows that the heat transfer area of the complete plate heat exchanger is 15m2.

6. The letter 'N' indicates that the sealing material is nitrile-butadiene rubber, for short as NBR. The letter 'E' represents ethylene propylene diene monomer, for short as EPDM.

7. The character represents the floor-mounted type movable pressure plate. The 'I' indicates the dual support framework consisting of the fixed pressure plates. (suspension type)

Related Names

Heat Transfer Unit | Flat Plate Heat Exchanger | Forced Air Heat Exchanger

Links:https://www.globefindpro.com/products/45932.html

-

Double Effect Vacuum Evaporator

Double Effect Vacuum Evaporator

-

Mash System

Mash System

-

Multifunctional Herbal Extraction Plant

Multifunctional Herbal Extraction Plant

-

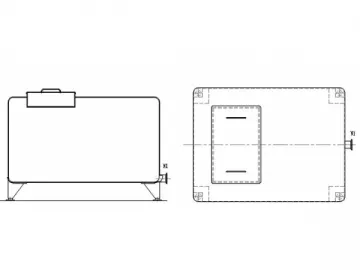

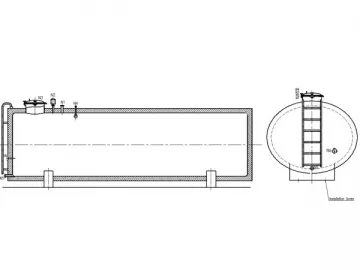

Milk Silo

Milk Silo

-

Glycol Chiller

Glycol Chiller

-

Milk Receiver Tank

Milk Receiver Tank

-

Malt Mill

Malt Mill

-

Single Effect Vacuum Evaporator

Single Effect Vacuum Evaporator

-

Stainless Steel Swageless Terminal

Stainless Steel Swageless Terminal

-

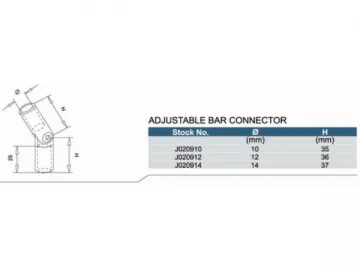

Stainless Steel Adjustable Upright Tube-Bar Connector

Stainless Steel Adjustable Upright Tube-Bar Connector

-

Milk Transfer Tank

Milk Transfer Tank

-

Stainless Steel 135 Degree Elbow

Stainless Steel 135 Degree Elbow