TPR Sole Mold

TPR Sole Mold

TPR sole mould, TPR sport shoe sole mould, TPR outsole mold, TPR outsolemolding

TPR sole mold can be applicable to the soleproduction for foamed and non foamed slow running shoes, leisure shoes, sneakers, and all kinds of sports shoes. For shoe solemaking, the mold can adopt foamed thermoplastic materials as its raw material.

Main Parameters

| Material | Iron |

| Product HS Code | 8480719090 |

| Mould Style | one mould one pair |

| Machine | Compatible with TPR Injection molding machine from Taiwan, Italy, China-mainland, and more countries and regions. |

| Size (L×W×H) | (200-400)×(150-240)×(80-220)mm |

| Weight | 50-1800kg |

| Package | Cardboard or three-ply board carton packing |

| Process | CNC modular or casting |

| Production Environment | 100℃-275℃ |

| Delivery | 20 days (after wooden mould checked) |

| Mould Life | More than 5 years |

Remarkable Features

Prominent characteristics of our TPR sole mold includegreat cost reduction, quick injection, as well as extremely good mould closing.In addition, this product is locked tightly, which greatly improves the qualityof the shoe soles without any burr.

Main Advantages

1. Our company has introduced allkinds of advanced machines to produce the high technology shoe sole mould. 45CNC machines and 4 computerdesign rooms can be available in our factory. Main machines include the three dimensionalscanner from Germany, bench work plant and testingmachine, American colorized three dimensional moldings machine, power shapesoftware for mould design, as well as 3, 4 or 5 axis programming or workshop.

2. For this TPR sole mold, we havealso established a huge sample room, where we place various types of sampleshoes from all over the world. We believe that the constantly updating stylescan really help our customers produce more competitive and popular shoes.

3. This mould is made of iron, which is of superior quality though a littleexpensive. Instead of the foundry molding, it wisely adopts four axisprocessing and precise engraving molding craft. Its whole production process strictlyimplements ISO9001:2000 to keep track of the international standard.

4. Inside our company, there are above 700 staffs, all of whom are working asfamilies and partners. Meanwhile, both upbeat music and mutual cooperation waycan bring them much optimism. Moreover, the two class workers shift work isable to ensure the timely delivery of the order of every customer. With ourbest product and services, we are confident to meet the needs of all customers.

Related Names

Thermoplastic Rubber Outsole Mould | Thermoplastic Elastomer Sole Molding | Outsole Mold Design

Links:https://www.globefindpro.com/products/46412.html

-

EVA Double Color Shoe Injection Mould

EVA Double Color Shoe Injection Mould

-

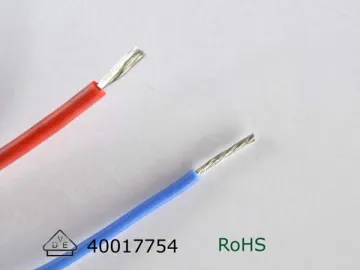

VDE Silicone Wire

VDE Silicone Wire

-

CCC/IEC Silicone Rubber Wire

CCC/IEC Silicone Rubber Wire

-

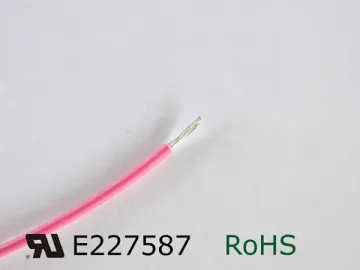

UL 3343 XLPE Wire / Cable

UL 3343 XLPE Wire / Cable

-

PVC Air Blowing Sandal Shoe Mould

PVC Air Blowing Sandal Shoe Mould

-

PVC Air Blowing Slipper Mould

PVC Air Blowing Slipper Mould

-

EVA Garden Shoe Injection Mould

EVA Garden Shoe Injection Mould

-

EVA Two-Color Sport Shoe Sole Once Injection Mould

EVA Two-Color Sport Shoe Sole Once Injection Mould

-

Mould Making Process

Mould Making Process

-

PVC Air Blowing Rain Boot Mould

PVC Air Blowing Rain Boot Mould

-

UL 3266 XLPE Wire / Cable

UL 3266 XLPE Wire / Cable

-

EVA Cotton Shoe Injection Mold

EVA Cotton Shoe Injection Mold