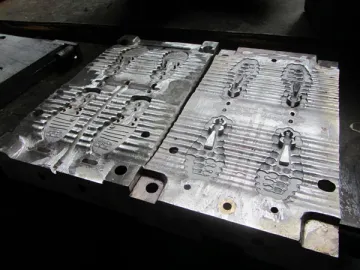

Crystal Shoe Mold

Crystal Shoe Mold

PVC crystal air-blowing slipper mould,crystal slipper mould, PVC crystal upper shoe mold, crystal shoe mold, crystalshoe molding

Crystal shoe mold is aonce injection type product that can save much cost during the production ofshoes. It is specially designed to manufacture various kinds of slippers,sandals and boots. Depending on the color of PVC materials, the shoes made bythis kind of mould are extremely transparent and colorful.

Technical Parameters

| Material | Iron |

| Shoe Mould HS Code | 8480719090 |

| Mould Style | One mould one piece |

| Machine | The crystal shoe mold is compatible with PVC crystal injection machine from Taiwan, Italy, China-mainland, and other countries and regions. |

| Size (L×W×H) | (350-450)×(180-280)×(100-275)mm |

| Weight | 35-200kg |

| Package | Cardboard or Three-ply board carton packing |

| Process | CNC modular or casting |

| Production Environment | 175℃-220℃ |

| Delivery | 20 days (after wooden mould checked) |

| Mould Life | More than 5 years |

Main Features

This crystal shoe mold is fine finished. It adopts theprofessional design of the feed opening that helps make quick injection. Weprovide samples for trail use. To ensure flexibility, our product isparticularly made to be adjustable in production. Also, it is tightly lockableto make the end product provide high quality without any burr. Owing to themold air blowing valve, the finished product may be lighter.

Advantages

1. As we all know, scienceand technology constitute the primary productive forces. To produce hightechnology crystal shoe mold, we make full use of 3, 4 or 5 axis programming orworkshop, as well as the three dimensional scanner from Germany, colorized three dimensional moldingsmachine from United States,bench work plant and testing machine, and power shape software for moulddesign. Also, there are 45 CNC machines and 4 computer design rooms in ourfactory.

2. Moreover, 2 huge sample rooms can be found in our company. One room is forPVC crystal shoe mold, and the other one is for EVA shoe mould. All our sampleshoes come from all over the world. Customers can benefit a lot from theconstantly updating styles to produce much more competitive shoes.

3. As the raw material of our mould, this Guangdong Zhiyuan 712 aluminum is the most expensive in China but canoffer the highest quality. By adoption of the two class workers shift work, theorder of every customer can be timely delivered. Through the joint efforts ofmore than 700 workers in our company, we are confident to make the best productand services so as to satisfy every customer.

,:

()TIENKANG/KINGSTEEL(、)(Suitable for TIENKANG,KINGSTEEL machines from Taiwan, and machines made in China mainland.)

Links:https://www.globefindpro.com/products/46430.html

-

UL3573 High Voltage Lead Wire

UL3573 High Voltage Lead Wire

-

UL 3253 High Temperature Electrical Wire

UL 3253 High Temperature Electrical Wire

-

Drainage Pipe Defrost Heater Wire / Cable

Drainage Pipe Defrost Heater Wire / Cable

-

FEP Tube

FEP Tube

-

UL Silicone Heating Wire / Cable

UL Silicone Heating Wire / Cable

-

Fiberglass Sleeve

Fiberglass Sleeve

-

UL Silicone Wire

UL Silicone Wire

-

PVC Air Blowing Cotton Shoe Mold

PVC Air Blowing Cotton Shoe Mold

-

PVC Air Blowing Garden Shoe Mould

PVC Air Blowing Garden Shoe Mould

-

EVA Insole Outsole Once Injection Mould

EVA Insole Outsole Once Injection Mould

-

EVA Slipper Injection Mould

EVA Slipper Injection Mould

-

Aluminum Pipe Heater

Aluminum Pipe Heater