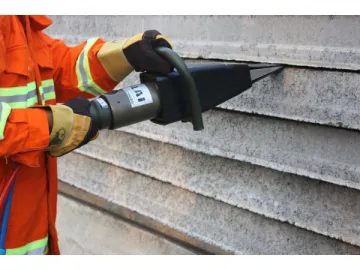

Manual Crowbar

Made of high-strength stainless steel, the working head of the manual crowbar features high strength, excellent corrosion-resistance and scientific configuration design. The anti-skid grooves are available for the handle. The manual crowbar has no need for power supplying. It can be carried easily by one person for its reasonable size and light weight. The tools are specially applied for the early work for earthquake rescue such as breaking open the doors, windows, locks, nails and bolts and the steel plate and timber plank of the collapsed building and damaged vehicle.

Structure of the Manual Crowbar

Top of the figure is QFS-A02 crowbar for pulling out the nails and prying open the door.

Bottom of the figure is QFS-A01 crowbar for chiseling and cutting.

Main Technical Parameters of the Manual Crowbar

Item | Data |

Force on the Handle | 600-800N |

Force for Prizing Up the Door | ≥ 4000N |

Force for Prizing Up the Lock | ≥10000N |

Force for Pulling out the Nail | ≥10000N |

Thickness of the Steel Plate for Cutting( Q235 Steel) | ≤1.5mm |

Thickness of the Steel Plate for Drilling( Q235 Steel) | ≤1.5mm |

Weight | ≤5.3x2kg |

Dimension | 855*72*47mm |

| Packed Weight | ≤20.5kg |

Packaging Dimension | 975*370*120 mm |

Application Cases

Cautions

1. The manual crowbar of our company is designed according to the ergonomic principles, which can fully satisfy both right-handed and left-handed users.

2. The working heads of the tools is designed with different functions. The rescuer should exert the functions of the tools fully by using the tools flexibly. Meanwhile, the rescuers should pay attention to the safety of their own and the people around.

Links:https://www.globefindpro.com/products/46779.html

-

Hydraulic Wedge Jack

Hydraulic Wedge Jack

-

Glass Breaker Tool Sets

Glass Breaker Tool Sets

-

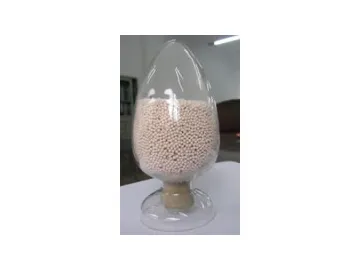

5A-RK29 Molecular Sieve for Desulphurization

5A-RK29 Molecular Sieve for Desulphurization

-

Loop Airflow Hatcher for Tunnel Incubator

Loop Airflow Hatcher for Tunnel Incubator

-

Metallurgy Big Parts

Metallurgy Big Parts

-

Incubation Equipment

Incubation Equipment

-

Li-LAX20 VPSA & PSA Lithium Molecular Sieve

Li-LAX20 VPSA & PSA Lithium Molecular Sieve

-

Hydraulic Universal Pliers

Hydraulic Universal Pliers

-

Hydraulic Spreading Cutter

Hydraulic Spreading Cutter

-

Telescopic Ram

Telescopic Ram

-

Hydraulic Disc Cutting Saw

Hydraulic Disc Cutting Saw

-

Hydraulic Power Station

Hydraulic Power Station