Chick Counter and Packaging Equipment

Chick Counter and Packaging Equipment

The automaticchick counter and packaging equipment is composed of a chick-picking workbench,a chick conveyor belt, a channel counter conveyor belt and a U-shaped keelchain transmission line. And it has the functions of manual sorting out the unqualified chicks and also counting andpackaging the qualified ones.

Chick Counter Chick Packaging

Characteristics

1. The equipment is cost effective witha counting capability of 35,000 chicks per hour, which is 7 or 8 times moreefficient than manual work.

2. The countingand packaging is more precise than manual work. For example, the countingaccuracy is within three thousands while at the same time, manual counting isunstable with the extension of working time.

3. The chick counter and packaging equipmentis applicable to any kind of chickbaskets. Almost 95% of the chick baskets, including plastic baskets and boxes canbe used on the equipment.

4. Our equipment is designed to avoid obvious and potential harm to thechicks. Also, the running speed of the conveyor belt ensures the counting efficiencyas well as the safety of the chicks.

5. The control system is capable ofadjusting the key parameters according to the body length of different chicksso that the system can maintain its accuracy under any conditions.

6. The simple and reasonable man-machineinterface can set up the chick numbers of each basket and display the currentchicks in every basket and the total numbers of boxes.

7. The chick counter and packaging equipment is scientifically designedto avoid direct contact between workers and chicks, and it also plays asignificant role in preventing human poultry cross-infection.

8. The equipment is made of high quality stainless steel, which isreliable and anti-rust. The electric component of the parts need to be washedhas a protection degree of above IP65.

Chick Counter andPackaging Equipment,,35U。。

,。,。,IP65,。,,。, 95%,35000,7~8,,。。,,。,,。,。,,。

Links:https://www.globefindpro.com/products/46788.html

-

2WD Telescopic Forklift, 4T Telehandler

2WD Telescopic Forklift, 4T Telehandler

-

Four Roll Double Sided Calendering Machine

Four Roll Double Sided Calendering Machine

-

Tray Washer of Hatchery Equipment

Tray Washer of Hatchery Equipment

-

Poultry Raising Equipment

Poultry Raising Equipment

-

Sexing Equipment of Hatchery Equipment

Sexing Equipment of Hatchery Equipment

-

Tunnel Incubator

Tunnel Incubator

-

Incubation Equipment

Incubation Equipment

-

Metallurgy Big Parts

Metallurgy Big Parts

-

Loop Airflow Hatcher for Tunnel Incubator

Loop Airflow Hatcher for Tunnel Incubator

-

5A-RK29 Molecular Sieve for Desulphurization

5A-RK29 Molecular Sieve for Desulphurization

-

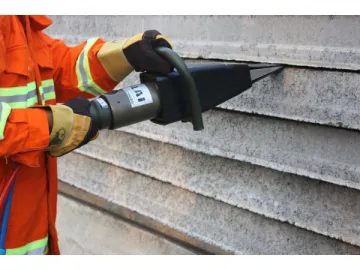

Glass Breaker Tool Sets

Glass Breaker Tool Sets

-

Hydraulic Wedge Jack

Hydraulic Wedge Jack