PE Film Extrusion Machine

PE Film ExtrusionMachine

The PE film extrusionmachine uses LDPE and HDPE as raw material for making PE film rolls. Afterheating, extrusion, blowing, drawing and rewinding, the LDPE and HDPE materialsare made into plastic film rolls. Through cutting and sealing, the plastic filmin roll can be made into food packaging bags, plastic shopping bags, liner ofwoven bags, and more. Through single side or double side cutting, theplastic film made by our PE film extrusion machine is also ideal for use asmulch film, agricultural film, and more.

Main Technical Parameters of the PE FilmExtrusion Machine

| Type | Diameter of screw (mm) | Length/diameter ratio of the screw | Screw rotational speed (r/min) | Power of main motor (kw ) | Heating power (kw ) | Production capacity (kg/h) | Max. film width (mm) | Film thickness (mm) | Installation Dimension (L×W×H) (mm) | Weight (kg) |

| SJ-FM55/800 | 55 | 28:1 | 15-90 | 15 | 13 | 15-40 | 800 | 0 .00 6-0 .05 | 4000×2600×3600 | 2600 |

| SJ-FM65/1000 | 65 | 28:1 | 15-80 | 18.5 | 18 | 20-55 | 1000 | 0.006-0.05 | 4300×2600×3900 | 3500 |

We are a specialized PE film extrusion machine manufacturer in China.At Yanfeng we also provideplastic recycling granulator, gravure printing machine, plastic flat filmextrusion machine, and four shuttle circular loom, among others.

Links:https://www.globefindpro.com/products/46999.html

-

Flexo Printing Machine

Flexo Printing Machine

-

High Speed Plastic Recycling Granulator

High Speed Plastic Recycling Granulator

-

Plastic Recycling Granulator

Plastic Recycling Granulator

-

Plastic Drying Mixer

Plastic Drying Mixer

-

Reverse Laminating Machine

Reverse Laminating Machine

-

Railway Bolt

Railway Bolt

-

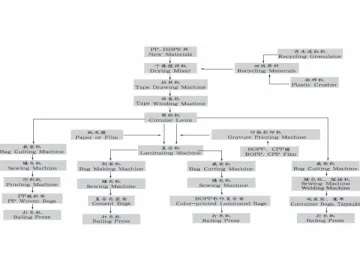

Woven Bag Production Line

Woven Bag Production Line

-

Gravure Printing Machine

Gravure Printing Machine

-

Film Sealing Cutting Machine

Film Sealing Cutting Machine

-

Little Cam Circular Loom

Little Cam Circular Loom

-

Big Six Shuttle Circular Loom

Big Six Shuttle Circular Loom

-

Co-Extrusion Film Blowing Machine

Co-Extrusion Film Blowing Machine