Reverse Laminating Machine

Reverse LaminatingMachine

The reverse laminatingmachine gets the tubular fabric with liner heated, thus laminating the linerand fabric together. With good moisture proof function, the laminated fabriccan be conveniently piled, and is ideal material for making packaging bags forfertilizer, chemical materials, animal feed and sugar, etc.

Functions of the Reverse LaminatingMachine

1. Our reverse laminatingmachine is PLC controlled and has touch screen operation system, automatictemperature and speed control system, malfunction alarming function, etc. Withthese functions, the lamination machine is convenient and safe for operation.

2. In addition to automatic temperature and speed control, the reverselaminating machine also comes with manual adjustment on heating temperature andlamination speed, so as to make sure the fabric and the liner are fedsynchronously and laminated smoothly.

3. The reverse laminating machine is manufactured with a pneumatic frictionalrewinding unit driven by a torque motor. This ensures smooth laminated fabricrewinding and allows us to get flat and even fabric roll.

Main Technical Parameters of the ReverseLaminating Machine

| Type | Bag width (mm) | Max. diameter of fabric roll (mm) | Max. lamination speed (m/min) | Heating power (kw) | Total power (kw) | Installation Dimension (L×W×H) (mm) | Gross weight (kg) |

| YF-NM F/650 | 350-650 | 1200 | 50 | 36 | 10 | 2200 ×1700 ×3100 | 10000 |

| YF-NM F/750 | 450-750 | 1200 | 50 | 48 | 14 | 2200 ×1700 ×3100 | 12000 |

Technical parametersof the reverse lamination machine are subject to change without prior notice!

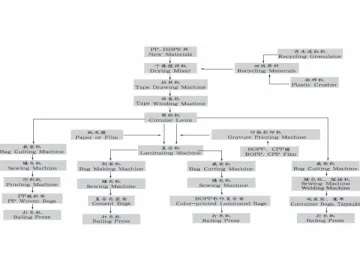

As a specialized reverse laminating machine manufacturer in China, we alsooffer OPP/CPP laminating machine, PP non-woven fabric production line, plasticfilm winding machine, bag sewing machine, and much more.

Links:https://www.globefindpro.com/products/47005.html