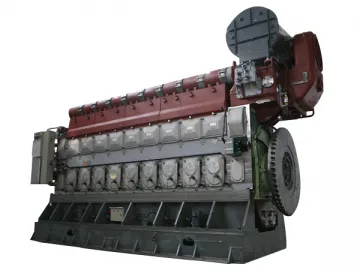

Diesel Engine Hydraulic Coupling Gear Box Set

Application of Speed-Adjustable Hydraulic Coupling Gear Reducer

The speed-adjustable hydraulic coupling gear reducer matches with our 140, 190, 260, 320 series diesel engines, Caterpillar, Volvo, Cummins diesel engines or electric motors to drive mud pumps.

Description of Speed-Adjustable Hydraulic Coupling Gear Reducer

The hydraulic coupling gear box uses the combination of fixed tube oil draining and inlet valve regulating to achieve adjustment of speed. With advantages of on-load starting, overload protection, torsional vibration isolation, vibration mitigation, stepless speed regulation, and quick and steady clutch, the gear reducer is an ideal choice for the variable speed drive of slush pumps.

Technical Indicators of Speed-Adjustable Hydraulic Coupling Gear Reducer

Input speed: 1000~1500 r/min

Transmitted power: 200~3000 kW

Rated efficiency: ≥96%

Rated slip: 3%

Gear reduction ratio: 2.0~3.3 (according to customers' specific needs)

Range of speed regulation: 1~1/3

Clutch sensitivity: 6~8S

Our hydraulic coupling gear reducers are newly developed products for the mud solid control circulating system of mud pumps. The reducers use fixed tube speed regulating technology, providing stepless control of coupling speed and quick, steady clutch. They work perfectly with the mud pumps for oil drilling domestically.

The advantages of our diesel engine hydraulic coupling gear box set working with mud pumps are given below:

1. The diesel engine hydraulic coupling gear box used for driving slush pumps, avoids the use of belt transmission, mechanical reducer and airbag clutch, offers simplified drive system, improved efficiency, reduced size and weight, and is easier to move.

2. The diesel engine and hydraulic coupling gear box are connected by high-elastic shaft coupling and are fitted onto the common chassis. The use of combined, high pressure water cooling ensures simplified structure of coupling cooler, reduced power consumed by auxiliary system consumption of auxiliary power, and compact structure.

3. When the hydraulic coupling gear box is used in driving slush pumps, it can completely meet the different displacement and pump pressure requirements under different working conditions for drilling. It achieves adjustment of pump displacement and pressure either by adjusting the throttle of the diesel engine or exchanging the liner. In addition, the displacement and pressure of the slush pump can be steplessly changed within a certain range by regulating the opening of the coupling pneumatic control valve, so that the diesel engine keeps working high efficiently (at a speed≥1000r/min).

4. It has the function of a clutch, conducting smooth clutch without impact or wear.

The diesel engine hydraulic coupling gear box set (consisting of a hydraulic coupling gear reducer and a power machine) is a new type hydraulic transmission product specially designed by Jinan Diesel Engine Company Limited (JDEC) in view of features of working conditions for the slush pump of oil drill. It is used to replace the diesel-driven single mud pump unit, eliminating traditional devices like mechanical reducer, airbag clutch, and drive belt. The diesel engine hydraulic coupling gear box set has compact structure, and is easy to operate and to maintain. With a wide power range of 105kW (140Hp)-3000kW (4000Hp), the product can completely meet the requirement for 200-2200Hp slush pump drive.

The power machine uses diesel engine or electric motor. Under circumstances of electric motor drive and full utilization of electric power resource from power grid, it can save energy cost by over 40%.

Links:https://www.globefindpro.com/products/47463.html

-

Diesel Engine 12V26/32

Diesel Engine 12V26/32

-

12V32/40 Diesel Engine

12V32/40 Diesel Engine

-

Biogas Generator (500KW/1100KW)

Biogas Generator (500KW/1100KW)

-

6-Cylinder Marine Engine (330~540kW)

6-Cylinder Marine Engine (330~540kW)

-

2000 Marine Engine (800~1000KW)

2000 Marine Engine (800~1000KW)

-

Locomotive Diesel Engine

Locomotive Diesel Engine

-

YOJ420, 580 Hydraulic Coupling

YOJ420, 580 Hydraulic Coupling

-

2000 Hydraulic Coupling Gear Reducer

2000 Hydraulic Coupling Gear Reducer

-

9L 32/40 Diesel Engine

9L 32/40 Diesel Engine

-

Long-stroke Marine Engine 4000 (1000, 1200Kw)

Long-stroke Marine Engine 4000 (1000, 1200Kw)

-

Crawler Bulldozer

Crawler Bulldozer

-

Hydraulic Single Drum Vibratory Roller

Hydraulic Single Drum Vibratory Roller