Paper Cup Printing Machine

Paper CupPrinting Machine

Description of Paper CupPrinting Machine

Flexo printing machine are new developed machines forsingle side coated and double side coated paper. They are suitable for PVC andOPP, etc.

The flexo printing machineapplies ceramic anilox to transfer ink, and itsunwinding and rewinding are controlled by magnetic power brake and tensioncontroller. As a result, it is easy to operate. Each printing unit utilizesprinting plate that can be fixed and adjusted in 360 degree. And each printingunit has one IR dryer. However, UV dryer is available if necessary. When PaperCup Printing machine stops, ink roll moves away, and runs in low speed to avoidink being dry.

Also, the printing width can be adjusted as customer'srequirement. Hence, the Paper Cup Printing machine is an ideal machine for printing factory to print many kinds of paper cup.

Features of Paper Cup Printing Machine

Applying the anilox roller to spread ink;

Using automatic tension controller that is imported from Japan to controlunwinding tension;

One IR dryer in each printing unit;

Adopting the imported motor with the stepless regulation of frequency conversion;

Unwinding, web guiding, printing, IR drying and rewinding can be finished inone process.

Main parameters of Paper Cup PrintingMachine

| Model | TH-C5A | TH-C5B |

| Printing speed | 60 m /min | 60 m /min |

| Printing color | 5 colors | 5 colors |

| Width of roll (Max.) | 660mm | 860mm |

| Printing width (Max.) | 650mm | 850mm |

| Unwinding Diameter (Max.) | 1400mm | 1400mm |

| Rewinding Diameter (Max.) | 1400mm | 1400mm |

| Printing girth | 175-380mm | 175-380mm |

| Printing accuracy | ±0.1mm | ±0.1mm |

| Overall dimensions(L*W*H) | 4000*1700*2700mm | 4000*1900*2700mm |

| Weight | About 5000kg | About 6000kg |

Links:https://www.globefindpro.com/products/47594.html

-

Automatic Cake Plate Making Machine

Automatic Cake Plate Making Machine

-

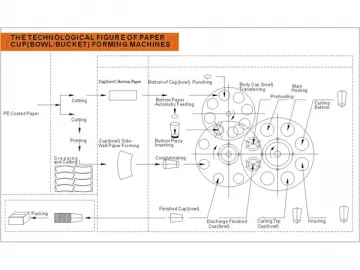

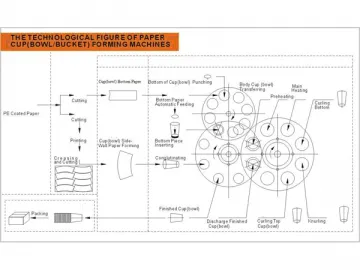

Paper Cup Forming Machine

Paper Cup Forming Machine

-

Paper Cup Shaper

Paper Cup Shaper

-

Concrete Paving Brick Machine, Concrete Curb Forming Machine YX-2000S/3000S

Concrete Paving Brick Machine, Concrete Curb Forming Machine YX-2000S/3000S

-

Plastic Cup Lid Machine

Plastic Cup Lid Machine

-

Paper Barrel Forming Machine

Paper Barrel Forming Machine

-

Double-Coated Paper Cup Machine (PE Laminating Film)

Double-Coated Paper Cup Machine (PE Laminating Film)

-

Paper Bowl Shaper

Paper Bowl Shaper

-

Paper Cup Overcoating Machine

Paper Cup Overcoating Machine

-

Conical Ice-Cream Paper Cup Shaper

Conical Ice-Cream Paper Cup Shaper

-

Concrete Paving Brick Machine, Concrete Curb Forming Machine YX-1500K

Concrete Paving Brick Machine, Concrete Curb Forming Machine YX-1500K

-

Hydraulic Water Well Drilling Rig YS Series

Hydraulic Water Well Drilling Rig YS Series