Fully Automatic Block Making Production Line

Fully Automatic Block Making Production Line

Description

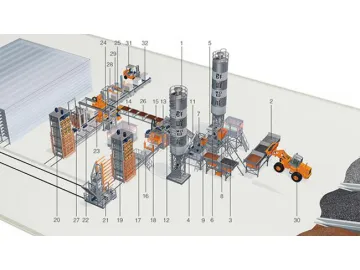

The fully automatic block making production line consists of an automatic batching and mixing system, forming system, automatic conveying system, pallets returning system, pallets buffer system, cuber system, central integrated control system, and more. It is in highly automatic. The material feeding, mixing, conveying, curing and stacking can be carried out automatically. It is among the most reliable and most advanced models of Qunfeng.

Technical Parameters of the Fully Automatic Block Making Production Line

Pallet Size: 1100×950×(thickness)mm (Bamboo/Steel/Wood Pallets)

Cycle Time: 15~25sec.

Major vibration type: Table vibration

Vibration frequency: 2800~4500r/min.

Power for main forming machine: 45.38kW

Rating pressure: 21Mpa

Overall weight for main forming machine: 11615kg

Main machine dimension: 7380×2100×3090mm

(:)

1. Cement Silo

2. Concrete Batching Machine

3. Pigment Batching Machine

4. Screw Conveyor

5. Cement Scale

6. Concrete Mixer

7. Pigment Mixer

8. Mixed Material Transit Hopper

9. Mixed Pigment Transit Hopper

10. Mixing Platform

11. Belt Conveyor For Raw Material

12. Belt Conveyor For Pigment

13. Block Making Machine

14. Computer Control System

15. Auto. Color Feeding System

16. Wet Block Conveyor

17. Pedestrian Bridge

18. Block Brush

19. Elevator

20. Lowerator

21. Program-controlled Finger Cart

22. Cured Block Conveyor

23. Cuber

24. Pallets Brush

25. Pallets Turnover

26. Horizontal Pallets Conveyor

27. Tray Bin

28. Horizontal Packing Machine

29. Sword Type Packing Machine

30. Film Wrapping Machine

31. Loader

32. Forklift

Fully Automatic Block Making Production Line (Without Packing System) | |||

Item | No. | Name | Model |

Automatic Batching & Mixing System | 1 | Cement Silo(For Coarse material) | 100T |

2 | Cement Silo (For Pigment) | 45T | |

3 | Automatic Batching Machine | PL1200-III | |

4 | Screw Conveyor | φ219X5m | |

5 | Cement Scale (Including water scale) | Z3500 | |

6 | Concrete Mixer | JS750 | |

7 | Pigment Mixer (With Loading System and Water Pump) | JQM500 | |

8 | Mixed Material Transit Hopper | ||

9 | Mixed Pigment Transit Hopper |

| |

Forming System | 10 | Mixing Platform |

|

11 | Belt Conveyor for Pigment | 0.5×8.4m | |

12 | Belt Conveyor for Raw Material | 0.8×10.3m | |

13 | Transit Conveyor | 0.8×3.5m | |

14 | Block Making Machine(Including Hydraulic System) |

| |

15 | Mold Change Platform |

| |

16 | Auto. Color Feeding System |

| |

Transferring System | 17 | Wet Block Conveyor (Chain type L=11.6m) |

|

18 | Pedestrian Bridge |

| |

19 | Block Brushing Machine |

| |

20 | Elevator (9 Layers) |

| |

21 | Lowerator (9 Layers) |

| |

22 | Program-controlled Finger Cart |

| |

23 | Cured Block Conveyor (Walking mode L=17.37m) |

| |

24 | Automatic Cuber |

| |

25 | Pallets Brushing Machine |

| |

26 | Pallets Turnover |

| |

27 | Horizontal Pallets Conveyor (Walking mode L=10m) |

| |

28 | Pallets Oil-painting Machine |

| |

29 | Pallets Feeder |

| |

30 | Tray Bin |

| |

31 | Tray Bin Chain Type Conveyor (20m) |

| |

Electrical Control System | 32 | Central Control Room |

|

33 | Control System for Concrete and Pigment Mixer(with Automatic Wet Testing System) |

| |

34 | Control System for Main Machine Forming System (with Industrial Computer) |

| |

35 | Control System For Finger Cart |

| |

36 | Control System for Cuber |

| |

Note: | |||

1. Curing Room, Steel Track, Workshop and other supporting equipment should be supplied by the Buyer.2. All kinds of mold can be made per the customer's drawings | |||

Fully Automatic Block Making Production Line (Including Packing System) | |||

System | No. | Name | Model |

Automatic Batching & Mixing System | 1 | Cement Silo(For Coarse material) | 100T |

2 | Cement Silo (For Pigment) | 45T | |

3 | Automatic Batching Machine | φ219×5m | |

4 | Screw Conveyor | Z3500 | |

5 | Cement Scale (Including water scale) | PL1200-III | |

6 | Concrete Mixer | JS750 | |

7 | Pigment Mixer (With Loading System and Water Pump) | JQM500 | |

8 | Mixed Material Transit Hopper | —— | |

9 | Mixed Pigment Transit Hopper | —— | |

Forming System | 10 | Mixing Platform | —— |

11 | Belt Conveyor for Pigment | 0.5×8.4m | |

12 | Belt Conveyor for Raw Material | 0.8×10.3m | |

13 | Transit Conveyor | 0.8×3.5m | |

14 | Block Making Machine |

| |

15 | Mold Change Platform |

| |

16 | Auto. Color Feeding System |

| |

Transferring System | 17 | Wet Block Conveyor (Chain type L=11.6m) |

|

18 | Pedestrian Bridge |

| |

19 | Block Brushing Machine |

| |

20 | Elevator (9 Layers) |

| |

21 | Lowerator (9 Layers) |

| |

22 | Program-controlled Finger Cart |

| |

23 | Cured Block Conveyor (Walking mode L=17.37m) |

| |

24 | Automatic Cuber |

| |

25 | Pallets Brushing Machine |

| |

26 | Pallets Turnover |

| |

27 | Horizontal Pallets Conveyor (Walking mode L=10m) |

| |

28 | Pallets Oil-painting Machine |

| |

29 | Pallets Feeder |

| |

30 | Tray Bin |

| |

Electrical Control System | 31 | Central Control Room |

|

32 | Control System for Concrete and Pigment Mixer (with Automatic Wet Testing System) |

| |

33 | Control System for Main Machine Forming System (with Industrial Computer) |

| |

34 | Control System For Finger Cart |

| |

35 | Control System for Cuber |

| |

Automatic Packing System | 36 | Horizontal Packing Machine |

|

37 | Sword Type Packing Machine |

| |

38 | Film Wrapping Machine |

| |

39 | Conveyor |

| |

Note: | |||

1. Curing Room, Steel Track, Workshop and other supporting equipment should be supplied by the Buyer.2. All kinds of mold can be made per the customer's drawings. | |||

Qunfeng is a professional manufacturer and supplier of fully automatic block making production line based in China. Our company specializes in the production of block making machine, roof tile forming machine, concrete batching machine, mobile building waste block production line, etc.

Links:https://www.globefindpro.com/products/47621.html

-

Building Waste Treatment Equipment

Building Waste Treatment Equipment

-

Concrete Mixer JQ350

Concrete Mixer JQ350

-

Block Making Machine QF1000

Block Making Machine QF1000

-

Concrete Block Splitter

Concrete Block Splitter

-

Refuse Transfer Station

Refuse Transfer Station

-

Block Mould

Block Mould

-

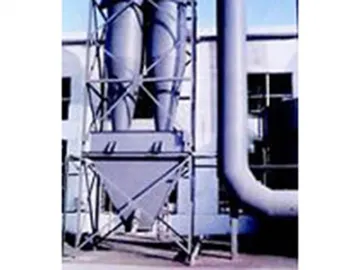

Cyclone Dust Collector

Cyclone Dust Collector

-

Concrete Batching Machine PL800-PL1600

Concrete Batching Machine PL800-PL1600

-

Concrete Mixer, JS Series

Concrete Mixer, JS Series

-

Pulverizer

Pulverizer

-

Drill Rod, Drill Pipe, Drill Stem

Drill Rod, Drill Pipe, Drill Stem

-

One-color Folio Offset Press

One-color Folio Offset Press