EPS Production Line

EPSProduction Line

Introduction of EPS

Expandable Polystyrene, EPS for short, is manufactured by combining styrenewith isobutylene under pressure. When manufacturing EPS products, tiny beads ofpoly styrene are expanded and consolidated in the process of steam heating andpressure treatment. When heated, the expanding agent enlarges the beads as muchas 50 times, after which they are fused by pressure into huge blocks of EPS.These blocks are cured, then cut and shaped to produce a variety of EPS products,bringing lots of benefits to the construction and packing industries.

Features of EPS

1. Excellent thermal insulation can reduce energy consumptiondramatically.

2. Lightweight strength enables more products to be transported on less fuel.

3. Maximum versatility: Cut to panel or molded, resistant to moisture andcompatible with a wide range of materials.

4. Easy to dispose with an integrated system to recycle and reuse.

Main Configuration of EPS Production Line

•Pre-expander

•EPS Block Molding Machine

•EPS Cutting Machine

•Auxiliary Equipments

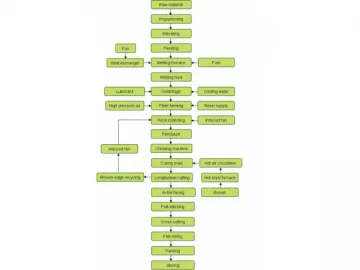

Flow Chart of EPSProduction Line

Raw materials -> Pre-expander -> Silos -> Shaping Machine / Blockshaping machine -> Cutter / CNC Cutter -> Blocks, and for the detailedinformation, please refer to the following chart:

TechnicalParameters of EPS Production Line

| Item | SPEN-3000 | SPEN-6000 | SPEN-8000 |

| Production Capacity (15Density (kg/m3), (kg/8 hours) | 3500 | 6900 | 9500 |

| Continuous Pre-expander | PE/C900 | PE/C900 | PE/C900 |

| Batch Pre-expander | PE/B1200 | PE/B1200 | PE/B1600 |

| Block Molding Machine | Air cooling or vacuum shaping | Air cooling or vacuum shaping | Air cooling or vacuum shaping |

| Block Cutting Machine | CM/G3000 (standard) or customer design | CM/G6000 (standard) or customer design | CM/G8000 (standard) or customer design |

| Recycling System | CR1250, DE1250, MI1250 | CR1250, DE1250, MI1250 | CR1250, DE1250, MI1250 |

| Silo (3x3x5.5m3) (set) | 6 | 10 | 12 |

| Steam Boiler (mt/h) | 1 | 2 | 2 |

| Power (without auxiliary equipments) (kw) | 85 | 105 | 120 |

| Workshop Area (m2) | Height≥6m | Height≥6m | Height≥6m |

| 1000 | 1500 | 2500 |

Note: All the parameters listed in theform are standard configuration.

Links:https://www.globefindpro.com/products/47692.html

-

Rotary Dryer

Rotary Dryer

-

Wood Plastic Composite Production Line

Wood Plastic Composite Production Line

-

Glass Wool Production Line

Glass Wool Production Line

-

110ml Glass Perfume Bottle 3145H

110ml Glass Perfume Bottle 3145H

-

130ml Glass Perfume Bottle H2081

130ml Glass Perfume Bottle H2081

-

110ml Glass Perfume Bottle 2738H

110ml Glass Perfume Bottle 2738H

-

Pulse Jet Baghouse Dust Collector

Pulse Jet Baghouse Dust Collector

-

170ml Glass Perfume Bottle 3121H

170ml Glass Perfume Bottle 3121H

-

Rock Wool Production Line

Rock Wool Production Line

-

3D Panel Production Line

3D Panel Production Line

-

110ml Glass Perfume Bottle 3101H

110ml Glass Perfume Bottle 3101H

-

180ml Glass Perfume Bottle 3139H

180ml Glass Perfume Bottle 3139H