Wood Plastic Composite Production Line

WoodPlastic Composite Production Line

Introduction of Wood Plastic Composite

With the feature of anti-acid, antiseptic, fireproof, waterproof and beautifuland elegant outlook, this building materials are becoming more and more popularall across the world and the market, now, has transferred from North America and EU to other countries. It is expectedthat WPC should replace pure wood in the near future. Moreover, WPC can betotally recycled and reproduced, dramatically reducing cost and influence onthe environment.

Advantages of Wood Plastic Composite Production Line

1. High quality: Several patents, advanced design, all-around service.

2. Official certificate: ISO9001 CE certificate

3. Long life time:Theworking life of screws and machine barrels is up to 15,000 hours.

4. Advanced controlling system: PLC controlling system and Omron sensors.

5. Famous international accessories: Siemens, Omron, ABB, etc.

6.Low energy consumption: our production line, compared with counterparts in China, can saveup to 50% energy cost.

7. Wide usage of raw materials: PP, PE, PVC, ABB and various wood powder and/orplant fiber

8. Excellent mixing ratio: Up to 70 percent of wood powder could be added,under the control of some special formulas.

TechnicalParameters of Wood Plastic Composite Production Line

| Item | QIZY-WPC-80 | QIZY-WPC -120 | QIZY-WPC -200 |

| Production Capacity (kg/h) | 55~80 | 85~120 | 125~200 |

| Extruder (Specific for WPC) | SJSZ-65 | SJSZ-80 | SJSZ-92 |

| Extruder Heating Power (kw) | 24 | 36 | 46 |

| Main Motor(kw) | 55 | 74 | 110 |

| Main Transducer | ABB | ABB | ABB |

| Contactor | Siemens | Siemens | Siemens |

| Vacuum Shaping Machine | ZDT-400 | ZDT-600 | ZDT-800 |

| Haul-off | QY-400 | QY-600 | QY-800 |

| Cutting Machine | QG-400 | QG-600 | QG-800 |

| Total Power (kw) | 91 | 124 | 199 |

| Weight (kg) | 6500 | 8600 | 10500 |

| Overall Dimension (L×W×H)(m) | 16×1.5×2.3 | 20×1.5×2.5 | 22×1.6×2.7 |

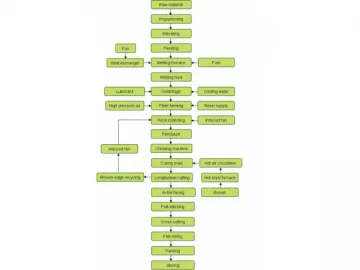

Flow Chart of Wood Plastic Composite Production Line

Wood fiber -> Fiber crusher dryer -> High speed mixer (Drying and mixing)-> Granulator -> Extruder -> Shaping and cooling -> Hauling off-> Cutting. And for the detailed information, please refer to the followingchart:

Links:https://www.globefindpro.com/products/47695.html

-

Glass Wool Production Line

Glass Wool Production Line

-

110ml Glass Perfume Bottle 3145H

110ml Glass Perfume Bottle 3145H

-

130ml Glass Perfume Bottle H2081

130ml Glass Perfume Bottle H2081

-

110ml Glass Perfume Bottle 2738H

110ml Glass Perfume Bottle 2738H

-

110ml Glass Perfume Bottle 2629H

110ml Glass Perfume Bottle 2629H

-

Roll-On Bottle T940

Roll-On Bottle T940

-

Rotary Dryer

Rotary Dryer

-

EPS Production Line

EPS Production Line

-

Pulse Jet Baghouse Dust Collector

Pulse Jet Baghouse Dust Collector

-

170ml Glass Perfume Bottle 3121H

170ml Glass Perfume Bottle 3121H

-

Rock Wool Production Line

Rock Wool Production Line

-

3D Panel Production Line

3D Panel Production Line