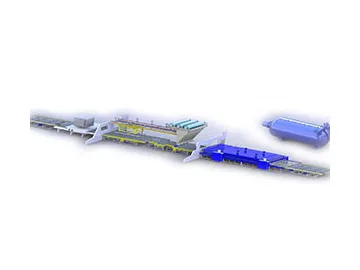

Semi-automatic Glass Laminating Line

Semi-automatic Glass LaminatingLine

Advantages

1.The semi-automatic glass laminating line provides PLC centralized control,touch screen and human-machine interface, which ensure easy operation.

2. It has advanced functions of remote control, data record and transmission,which facilitate production management and fault diagnosis.

3. The glass laminating line uses high performance washing machine which notonly helps improve the quality of laminated glass but also increase theproduction efficiency.

4. The laminating line offers an infrared heating preformingpress, and the optional forced convection system saves energy by over 40%.

5. Independent roll forming greatly improves the quality of glass,preventing poor alignment of glass caused by uneven speed of press roller.

Use

The semi-automatic glass laminating line is applied to making laminatedglass for architecture and decoration, industrial purpose, cars and boats, aswell as special purpose laminated glass and bent laminated glass with the heightof arc not exceeding 80mm.

Technical Parameters

| Model | Max. size of product (mm) | Min. size of product (mm) | Max. thickness of product (mm) | Installed power (kw) | Production capacity sqm/shift of 4G 0.38PVB 4G |

| AI-JC1645C | 1600 x 4500 | 150 x 250 | 4 ~ 40 | 195 | 280 |

| AI-JC2060C | 2000 x 6000 | 200 x 300 | 4 ~ 80 | 270 | 400 |

| AI-JC2560C | 2500 x 6000 | 200 x 300 | 4 ~ 80 | 315 | 500 |

| AI-JC2580C | 2500 x 8000 | 200 x 300 | 4 ~ 80 | 340 | 600 |

| AI-JC3080C | 3000 x 8000 | 240 x 420 | 4 ~ 80 | 440 | 750 |

| AI-JC3380C | 3250 x 8000 | 240 x 420 | 4 ~ 80 | 525 | 900 |

Yuntong is a professional semi-automatic glasslaminating line manufacturer in China.In addition, we offer continuous heating flat glass tempering furnace,energy-saving glass tempering furnace, float glass plant turnkey project, glassdistribution machine, and more.

Links:https://www.globefindpro.com/products/47841.html

-

ABS Cosmetic Cap 729

ABS Cosmetic Cap 729

-

Glass Cross Cutting Machine (including length measuring, signal generator and glass edge severing)

Glass Cross Cutting Machine (including length measuring, signal generator and glass edge severing)

-

Rubber Cosmetic Cap 1489

Rubber Cosmetic Cap 1489

-

Vertical Glass Washing Machine

Vertical Glass Washing Machine

-

PP Cosmetic Cap 533

PP Cosmetic Cap 533

-

Laminated Glass Production Line

Laminated Glass Production Line

-

50ml Glass Perfume Bottle 2518H

50ml Glass Perfume Bottle 2518H

-

50ml Glass Perfume Bottle T719

50ml Glass Perfume Bottle T719

-

50ml Glass Perfume Bottle 3094H

50ml Glass Perfume Bottle 3094H

-

50ml Glass Perfume Bottle 2748T

50ml Glass Perfume Bottle 2748T

-

50ml Glass Perfume Bottle T552

50ml Glass Perfume Bottle T552

-

20ml Glass Perfume Bottle T694

20ml Glass Perfume Bottle T694