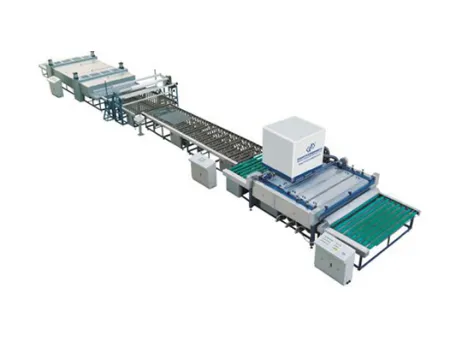

Automatic Glass Loading Machine

Automatic glass loading table Mechanical tilting table for unloading  Features SIMENS PLC control system for high control precision. Stable, reliable, and precise tilting arms. Suction cup vacuum lifter features mechanical transmission design and delivers stable and reliable glass handling operations. Fully automatic operations reduce labor cost and decrease human injury risk without close contact to glass. Complete protection devices for electrical system. Electrical components are branded products to ensure the quality, such as AirTac Cylinder and PUXU vacuum pump. The automatic glass loading machine is designed with the simplest operations and the highest productivity. Automatic Glass Loading Table

Features SIMENS PLC control system for high control precision. Stable, reliable, and precise tilting arms. Suction cup vacuum lifter features mechanical transmission design and delivers stable and reliable glass handling operations. Fully automatic operations reduce labor cost and decrease human injury risk without close contact to glass. Complete protection devices for electrical system. Electrical components are branded products to ensure the quality, such as AirTac Cylinder and PUXU vacuum pump. The automatic glass loading machine is designed with the simplest operations and the highest productivity. Automatic Glass Loading Table

Mechanical Tilting Table for Unloading

Handong automatic loading and unloading machine adopts the driving mode of mechanical sucker arm. The overall design is compact,and the reduction motor directly drives the turning arm through four connecting rods to turn over,which reduces and even avoids unnecessary errors during processing and assembly. It makes the driving more stable and smooth,which can connect seamlessly with various types of glass cutting equipment.

| Model | Glass size (mm) | Tilting angle (°) | Loading capacity (kg) | Min. loading time (s/glass sheet) | Installed power (kW) |

| 1700x1100 | 98° ±2° | 100 | 12 | 3.55 | |

| 3000x2500 | 98° ±2° | 400 | 35 | 5.2 | |

| 4200x2500 | 98° ±2° | 550 | 35 | 5.2 | |

| 3700x2700 | 98° ±2° | 600 | 50 | 5.55-9.8 | |

| 6100x3300 | 98° ±2° | 1000 | 50 | 6.65-13.55 |

Mechanical Tilting Table for Unloading

| Model | Glass size (mm) | Tilting angle (°) | Unloading capacity (kg) | Min. unloading time (s/glass sheet) | Installed power (kW) |

| 2500×4000 | 85° ±2° | 800 | 15S | 8.0 | |

| 2500×6000 | 85° ±2° | 1000 | 20S | 9.7 | |

| 3000×4000 | 85° ±2° | 800 | 15S | 8.0 | |

| 3000×6000 | 85° ±2° | 1000 | 20S | 9.7 | |

| 3300×4000 | 85° ±2° | 1000 | 15S | 9.7 | |

| 3300×6000 | 85° ±2° | 1500 | 20S | 9.7 |

So far, 1000 sets of glass loading and unloading tables have been sold to many countries and regions. Among them, hundreds of the tables have worked with LISEC, Botterol and INTERMAG glass cutter or VON ARDENNE glass coating machine.

Scan QR to Read

Links:https://www.globefindpro.com/products/48773.html

Links:https://www.globefindpro.com/products/48773.html

Recommended Products

-

Automatic Tube Filler and Sealer, ZHNG-100A

Automatic Tube Filler and Sealer, ZHNG-100A

-

TJJ700 Box Gluer

TJJ700 Box Gluer

-

ZD120 Cutting and Slitting Machine

ZD120 Cutting and Slitting Machine

-

Automatic Turret Rewinder, 2 Spindle Turret (YS-320FII/420FII)

Automatic Turret Rewinder, 2 Spindle Turret (YS-320FII/420FII)

-

Flat Bed Label Die Cutting Machine (YS-450A)

Flat Bed Label Die Cutting Machine (YS-450A)

-

Autoclave for Laminated Glass Manufacturing

Autoclave for Laminated Glass Manufacturing

-

Semi-Automatic Laminated Glass Production Line

Semi-Automatic Laminated Glass Production Line

-

FM600C Folding Machine

FM600C Folding Machine

-

Casing In Machine

Casing In Machine

-

SW1350 Cutting and Slitting Machine

SW1350 Cutting and Slitting Machine

-

Perfume Filling and Crimping Machine, ZHS-50

Perfume Filling and Crimping Machine, ZHS-50

-

Cream Filling and Capping Machine, ZHG-50B

Cream Filling and Capping Machine, ZHG-50B

Hot Products