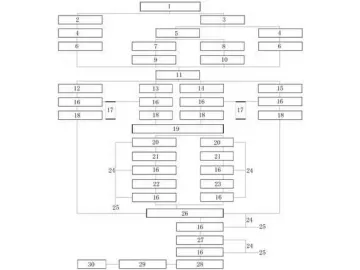

Manufacturing Equipment

1. Doors, windows and curtain wall systems

2. Processing with client-provided materials

3. Orders

4. Bill of process

5. Bill of plan

6. Bill of production scheduling

7. Materials(aluminum)

8. Hardware accessories

9. Business department

10. Material repository

11. Material entering the factory

12. Accessories

13. Profiles

14. Metal boards

15. Glass

16. Inspection

17. Returning goods

18. Stocking

19. Deep processing & manufacturing

20. Film applying & film protecting

21. Cutting

22. Punching, milling & joggling

23. Processing

24. Repairing & reprocessing

25. Non-conforming products

26. Accessories assembling

27. Silicone

28. Depositing

29. Packing (products protecting)

30. Stocking & delivering

Machining Workshop

Guangya has a complete range of production lines. Our machining workshop is equipped with 14 sets of CNC lathes to process workpieces with diversified sizes and specifications.

Automatic Machining Lathe

We have 2 CNC milling machines whose max sawing width is 300mm and max sawing length is up to 800mm. They can saw workpiece at any angle.

Sawing Workshop

8 horizontal sawing machines: max sawing width: 600mm; max sawing length: 15000mm;

7 CNC double miter saws: max sawing width: 400mm; max sawing length: 7000mm

Stamping Workshop

We have 17 pouching machines whose max capacity is 10 tons. At Guangya, each detail of our doors and windows is manufactured strictly according to the quality standards.

Welding Workshop

The welding workshop is equipped with 3 automatic welding arms and 12 argon arc welding machines, which allow for higher working efficiency and more uniform welding operation

Maintenance and Rubber Injection Workshop

We have introduced 5 rubber injection machines. Our staffs are checking the products in the maintenance workshop

Assembly Workshop

Mold Warehouse

Accessory Warehouse

Raw Material Warehouse

Packaging and Shipping

Links:https://www.globefindpro.com/products/49254.html

-

6 Pole Alternator

6 Pole Alternator

-

Horizontal Type EPS Light Weight Wall Panel Production Line

Horizontal Type EPS Light Weight Wall Panel Production Line

-

Fiber Laser Tube Cutting Machine

Fiber Laser Tube Cutting Machine

-

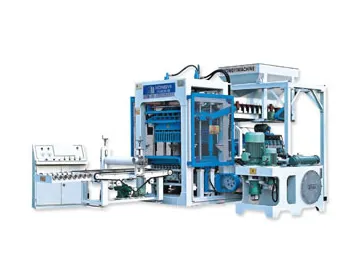

Paving Block Machine

Paving Block Machine

-

DNE Laser Cutting Machine

DNE Laser Cutting Machine

-

Aluminum Alloy Casement Window

Aluminum Alloy Casement Window

-

Thermal Break Aluminum Alloy Sliding Door

Thermal Break Aluminum Alloy Sliding Door

-

Aluminum Alloy Frame

Aluminum Alloy Frame

-

Curtain Wall Hardware

Curtain Wall Hardware

-

To 2000kg Heavy Duty Polyurethane Tyred Wheels

To 2000kg Heavy Duty Polyurethane Tyred Wheels

-

Fiber Laser Cutting System

Fiber Laser Cutting System

-

AGV Polyurethane Tyred Wheel (Automated Guided Vehicle Wheel)

AGV Polyurethane Tyred Wheel (Automated Guided Vehicle Wheel)