Germany Technology Best Service

Features:

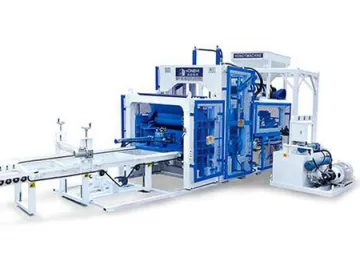

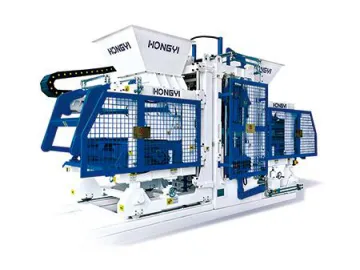

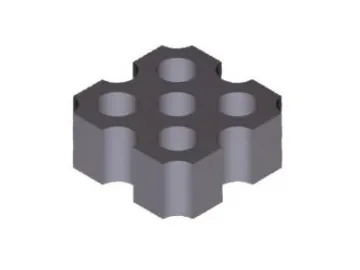

It is applicable to the production of larger blocks, such as road traffic stone, large-scale water conservancy and hydraulic products, municipal pavement bricks and revetment block, etc. Four-axis synchronous vibration system configuration as well as special self-lubrication design can reduce the number of times of shutdown repairing and increase the service life of vibrator. Air bag device can reduce the impact loss of vibration on the machine and improve the quality of finished products. Technical Parameters:

Production Capacity:

It is applicable to the production of larger blocks, such as road traffic stone, large-scale water conservancy and hydraulic products, municipal pavement bricks and revetment block, etc. Four-axis synchronous vibration system configuration as well as special self-lubrication design can reduce the number of times of shutdown repairing and increase the service life of vibrator. Air bag device can reduce the impact loss of vibration on the machine and improve the quality of finished products. Technical Parameters:

| Overall dimension | 5300×2450×2850mm | Vibration method | Synchronous mode of table & mould |

| Pallet size | 1400×950×45mm(Wooden) | Vibration frequency | 50-70Hz |

| Working area | 1300×900mm | Machine Power | 62kW |

| Machine weight | 15500kg | Cycle time | 15s-25s |

Production Capacity:

| Specification of products (mm) | Number of blocks per pallet | Pieces/hour | Pieces/8 hours | Pieces/300 days (two shifts) | ||

| Block | 390×190×190 | 12 | 2,880 | 23,040 | 13,824,000 | |

| Hollow Brick | 240×115×90 | 30 | 7,200 | 57,600 | 34,560,000 | |

| Paving Brick | 225×112.5×60 | 30 | 7,200 | 57,600 | 34,560,000 | |

| Standard Brick | 240×115×53 | 60 | 14,400 | 115,200 | 69,120,000 | |

Scan QR to Read

Links:https://www.globefindpro.com/products/49286.html

Links:https://www.globefindpro.com/products/49286.html

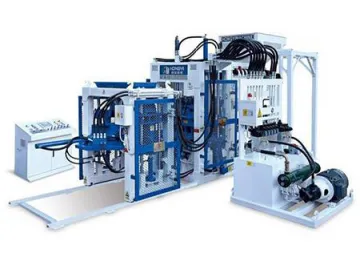

Recommended Products