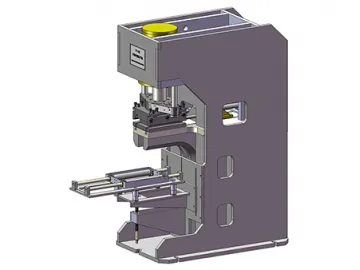

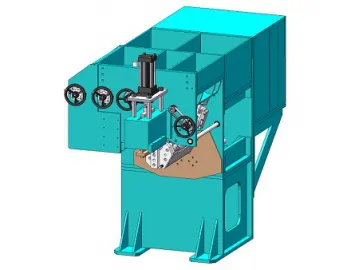

Tubeless Rim Re-rounders

Tubeless rim re-rounders are used to re-round the welded joint on wheel rims after the trimming-planishing-side trimming operations are complete. This facilitates subsequent rim flaring and roll forming processes and helps lower the rejection rate, while simultaneously improving product quality. The tubeless rim re-rounder has a dual power hydraulic system and is comprised of the main machine, the drive mechanism, and the electric control cabinet.

Scan QR to Read

Links:https://www.globefindpro.com/products/4951.html

Links:https://www.globefindpro.com/products/4951.html

Recommended Products

-

Butt Welding Machine

Butt Welding Machine

-

Complete Grinding System

Complete Grinding System

-

Disk And Rim Assembly Welder

Disk And Rim Assembly Welder

-

Tubeless Rim Band Coiler

Tubeless Rim Band Coiler

-

Factory Tour

Factory Tour

-

Mobile Evaporative Air Cooler (Large-scale)

Mobile Evaporative Air Cooler (Large-scale)

-

Wheel Disk Vertical Turning Lathe , Gantry Type

Wheel Disk Vertical Turning Lathe , Gantry Type

-

Grinding Systems for Digital Ink and Printing

Grinding Systems for Digital Ink and Printing

-

Commercial / Residential Evaporative Cooler

Commercial / Residential Evaporative Cooler

-

Single Beam Gantry Crane, with L-shaped Legs

Single Beam Gantry Crane, with L-shaped Legs

-

Trimmer Machine for Tube Wheel Rim

Trimmer Machine for Tube Wheel Rim

-

Wheel Rim Vertical Wheel Rim Turning Lathe

Wheel Rim Vertical Wheel Rim Turning Lathe