Disk And Rim Assembly Welder

Taizhi’s assembly welders are designed for internal welding of 22.5 to 24.5-inch tubeless steel wheels.

Scan QR to Read

Links:https://www.globefindpro.com/products/4954.html

Links:https://www.globefindpro.com/products/4954.html

Recommended Products

-

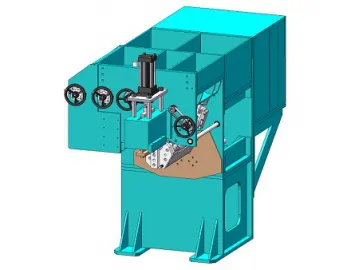

Tubeless Rim Band Coiler

Tubeless Rim Band Coiler

-

Factory Tour

Factory Tour

-

Mobile Evaporative Air Cooler (Large-scale)

Mobile Evaporative Air Cooler (Large-scale)

-

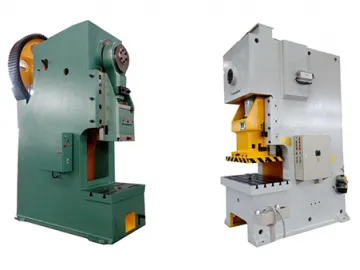

Steel Wheel Disk Vent Hole Punching Press

Steel Wheel Disk Vent Hole Punching Press

-

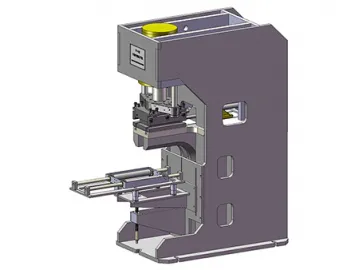

Framed Hydraulic Press

Framed Hydraulic Press

-

Horizontal Air Leakage Testing Machine

Horizontal Air Leakage Testing Machine

-

Complete Grinding System

Complete Grinding System

-

Butt Welding Machine

Butt Welding Machine

-

Tubeless Rim Re-rounders

Tubeless Rim Re-rounders

-

Wheel Disk Vertical Turning Lathe , Gantry Type

Wheel Disk Vertical Turning Lathe , Gantry Type

-

Grinding Systems for Digital Ink and Printing

Grinding Systems for Digital Ink and Printing

-

Commercial / Residential Evaporative Cooler

Commercial / Residential Evaporative Cooler