Industrial Cable Manufacturer

Description

Feature

The layer stranded structure allows the connector to withstand a greater tension.

The cable is fire-retardant.

The aramid fiber strength member gives the cable a great tensile strength.

The 4-core BOC fiber optic connector is torsion resistant.

The sheath is abrasion resistant, aging resistant, oil resistant, LSZH fire-retardant and features a high performance.

The connector uses all dielectric materials and is immune to EMI.

The 4-core BOC fiber optic connector is expertly designed and produced.

Specification

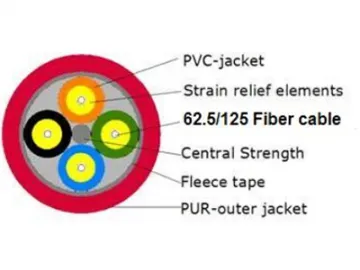

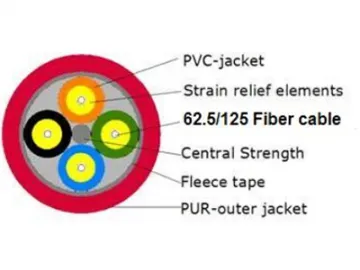

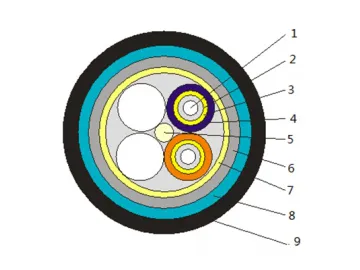

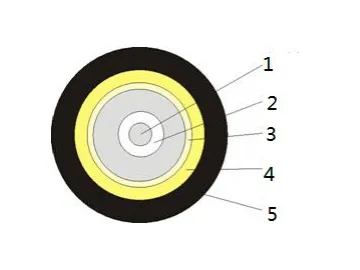

The 4-core BOC fiber optic connector used multimode optical glass fiber as the sub-element, with a nonmetal core. The sub-element layer is stranded around the nonmetal core to form the cable core. The exterior layer is a PUR sheath.

We can also produce other multicore fiber optic connectors, e.g. 6-core and 8-core, according to customer requirements.

Feature

The layer stranded structure allows the connector to withstand a greater tension.

The cable is fire-retardant.

The aramid fiber strength member gives the cable a great tensile strength.

The 4-core BOC fiber optic connector is torsion resistant.

The sheath is abrasion resistant, aging resistant, oil resistant, LSZH fire-retardant and features a high performance.

The connector uses all dielectric materials and is immune to EMI.

The 4-core BOC fiber optic connector is expertly designed and produced.

Specification

| Structure of control cable | 4-core |

| Strength member | Nonmetal aramid fiber |

| Color of sheath | Black |

| Material of sheath | PUR |

| Insertion loss of control cable | ≤1.0dB |

| connector | 4*SC at each end Branch length: 50cm |

| Total loss of the control cable | ≤5.0dB |

| Outer diameter of cable | about 10 mm (PUR sheath) |

| Weight of control cable | About15kg |

| Max short-term tension (cable) | 660N |

| Max long-term tension (cable) | 200N |

| Crush pressure (long/short-term per100mm) | 300N/1000N |

| Min bending radius | 10 times of cable' s diameter (PUR sheath) |

| Operation temperature: | -45℃~+80℃(PUR) |

| Storage temperature | -45℃~+80℃(PUR) |

| Optical fiber performance | |

| Optical fiber | MM 9/125 |

| Diameter of optical fiber | 250µm |

| Attenuation | |

| @850nm | ≤3.5dB |

| @1300nm | ≤1.5dB |

| Detected item | Insertion loss & attenuation |

| Additional temperature attenuation△α(-20℃~+60℃) | ≤0.5dB |

| Effective transmission distance | 300M |

| Test | Torsion test: torsion angle is no less than ±1440°; report of torsion test at low temperature (≤-20℃) available |

| Attached technical document | License, instruction manual |

Scan QR to Read

Links:https://www.globefindpro.com/products/49981.html

Links:https://www.globefindpro.com/products/49981.html

Recommended Products

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Forged Control Arm for Automotive Suspension

Forged Control Arm for Automotive Suspension

-

Axle Torsion Arm Forgings for RV Trailer Suspension

Axle Torsion Arm Forgings for RV Trailer Suspension

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Forged Car Door Hinge

Forged Car Door Hinge

-

Forged Train Chassis Components

Forged Train Chassis Components

-

Forged Swing Arm for Chassis and Suspension

Forged Swing Arm for Chassis and Suspension

-

Axle Components Forged Spindle for RV Trailer Suspension

Axle Components Forged Spindle for RV Trailer Suspension

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

Hot Products