Industrial Cable Manufacturer

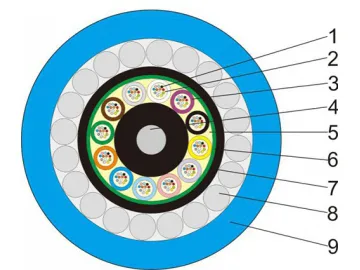

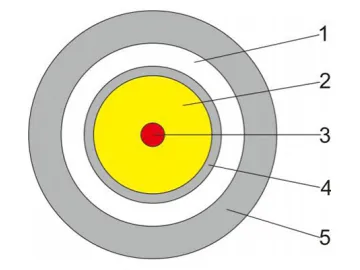

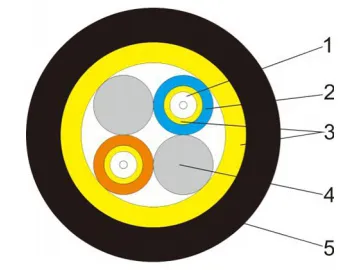

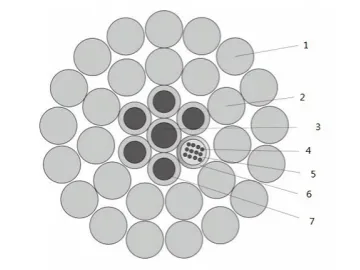

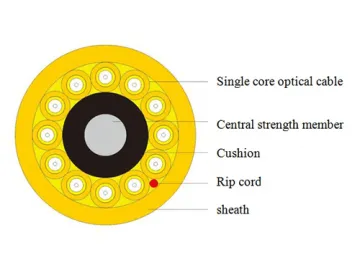

Structure

Optical fiber

Gel: water-blocking compound

Loose tube: thermoplastic material

Central strength member: phosphatized steel wire, high fiber count optical cable, extruded polyethylene

Water-blocking material: water-blocking filler

Armored layer: composite steel-plastic tape

Inner sheath: black polyethylene (possible)

Armored wire

Outer sheath: blue flame retardant sheath

Description of flame retardant steel wire armored fiber optic cable

Parameter Technical parameter

Parameter Technical parameter

Characteristic of optical fiber

Main machinery and environment performance

Features

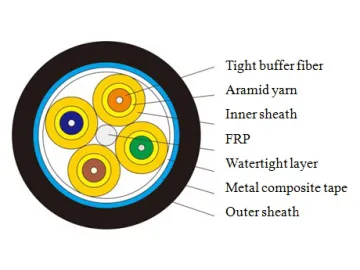

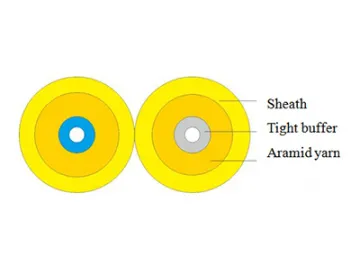

This optical fiber features excellent mechanical properties and temperature characteristics. The specific sheathe material is flame retardant. The optical cable uses fine and round armored wire, which has a higher tensile property. Installation

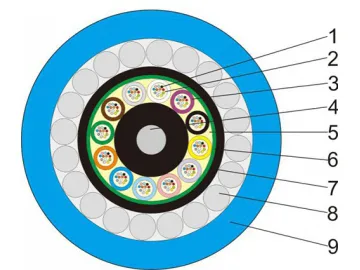

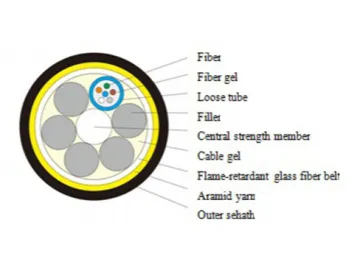

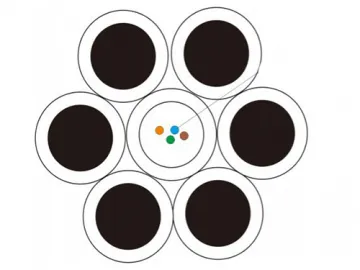

Optical fiber

Gel: water-blocking compound

Loose tube: thermoplastic material

Central strength member: phosphatized steel wire, high fiber count optical cable, extruded polyethylene

Water-blocking material: water-blocking filler

Armored layer: composite steel-plastic tape

Inner sheath: black polyethylene (possible)

Armored wire

Outer sheath: blue flame retardant sheath

Description of flame retardant steel wire armored fiber optic cable

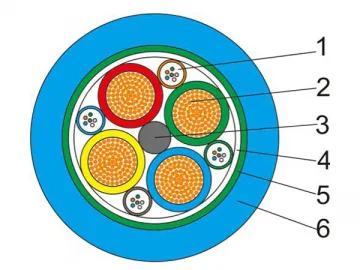

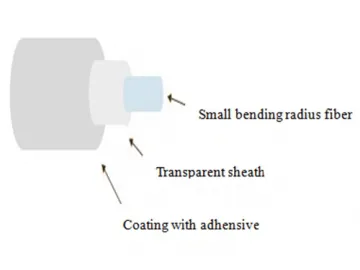

The flame retardant steel wire armored fiber optic cable uses a 250μm optical fiber in the loose tube of a high modulus material, and fills the remaining space in the tube with a waterproof compound.

A metal strength member is used as the core. For optical cables with a different core, a polyethylene layer should be extruded out of the metal strength member.

The loose tubes (with filler strip) are stranded around the strength member into a compact cable core which is then filled with the filling compound to protect it from water. The PSP tape, stranded with an armored wire, serves as a flame retardant sheathe.

| Item | Content | Value | |||||

| Number of cores | 24 | 48 | 72 | 96 | 120 | 144 | |

| Loose tube | Quantity of loose tube*quantity of core | 4*6 | 4*12 | 6*12 | 8*12 | 10*12 | 12*12 |

| Outer diameter of loose tube/mm | 1.8 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | |

| Reference outer diameter | mm | 12.0 | 13.5 | 14.5 | 16.0 | 17.5 | 19.5 |

| Central strength member | Material | Steel wire | |||||

| Water-blocking material | Material | Water-blocking gel | |||||

| Armored layer 1 | Material | Corrugated steel | |||||

| Inner sheath | Thickness (±0.1mm) | 0.9 | |||||

| Armored layer 2 | Material | fine and round zinc-coated wire | |||||

| Outer sheath | Thickness (±0.2mm) | 1.8 | |||||

| Operating temperature | ℃ | -40~+70 | |||||

| Tensile force | Short term/long term N | 2000/900 | |||||

| Flatten | 1500/400 | ||||||

| *We can design the structure and quantity of core according to customer requirements. | |||||||

| G.652.D | G.655 | 50/125μm | 62.5/125μm | ||

| Attenuation | @850nm | - | - | ≤3.0dB/km | ≤3.0dB/km |

| @1300nm | - | - | ≤1.0dB/km | ≤1.0dB/km | |

| @1310nm | ≤0.36dB/km | ≤0.36dB/km | - | - | |

| @1550nm | ≤0.22dB/km | ≤0.23dB/km | - | - | |

| Bandwidth | @850nm | - | - | ≥500MHz·km | ≥200MHz·km |

| @1300nm | - | - | ≥1000MHz·km | ≥600MHz·km | |

| Fiber cutoff wavelength | ≤1260nm | ≤1260nm | - | - | |

| Polarization mode dispersion | Single optical fiber | ≤0.20ps/√km | ≤0.20ps/√km | - | - |

| Link value (M=20, Q=0.01%) | ≤0.10ps/√km | - | - | ||

| Item | Inspection standard | Procedure of inspection | Requirements |

| Pull | IEC 60794-1-2-E1 | According to technical parameter | Additional attenuation for short term≤0.1dB |

| Flatten | IEC 60794-1-2-E3 | According to technical parameter | Additional attenuation for short term≤0.1dB |

| Impact | IEC 60794-1-2-E4 | punch hammer: 450g, height: 1m, 5 times at least | Residual additional attenuation≤0.03dB |

| Backward and forward bending | IEC 60794-1-2-E6 | Load: 150N, 30 times | Residual additional attenuation≤0.03dB |

| Twisting | IEC 60794-1-2-E7 | 1m , ±180°, 10 times | Residual additional attenuation≤0.03dB |

| Temperature recycle test | IEC 60794-1-2-F1 | -40℃ ~+70℃ | Additional attenuation≤0.05dB |

| Combustion performance | IEC 60332-1-2 | Fire resistance | The optical fiber will maintain its attenuation uniformity. |

| Flame retardant: every single wire can be burnt vertically. | The distance between lower edge of upper fixture and burnt point:>50mm | ||

| Flame retardant: combustion for bunched cable | Height of carbonized part<2.5m | ||

| Density of the smoke | Light transmittance ≥50% | ||

| * The monitoring of all optical fiber attenuation's change is operated in wavelength of 1550nm. | |||

This optical fiber features excellent mechanical properties and temperature characteristics. The specific sheathe material is flame retardant. The optical cable uses fine and round armored wire, which has a higher tensile property. Installation

Pipeline, Aerial, Direct buried, Vertical installation

Scan QR to Read

Links:https://www.globefindpro.com/products/50006.html

Links:https://www.globefindpro.com/products/50006.html

Recommended Products

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

Hot Products