Industrial Cable Manufacturer

Description of optical fiber cable for nuclear power plant  Application

Application

Features

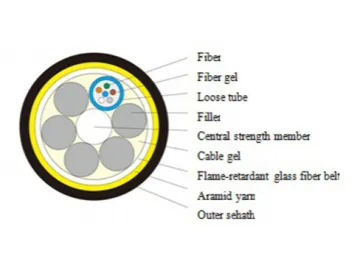

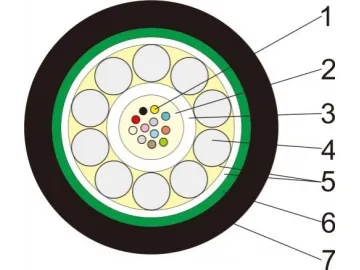

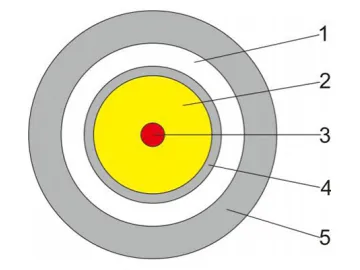

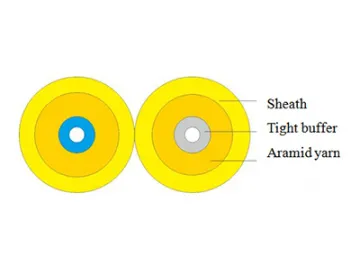

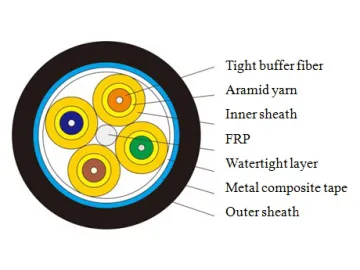

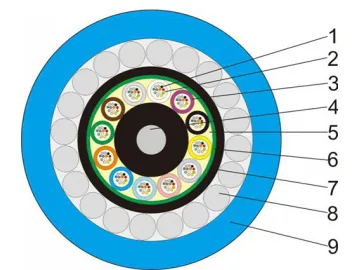

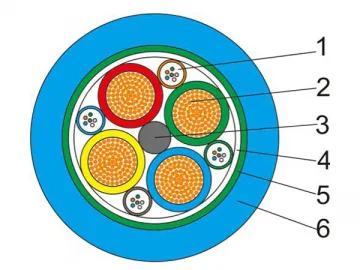

The outdoor stranded loose tube cable uses gel to fill itself in order to facilitate the tensile strength, moisture resistance and side pressure resistance. We use a nonmetal Fiber Reinforce Plastic (FRP) round bar at the center to strengthen the optical cable. The glass fiber yarn will protect the cable core and improve the flame retardant performance. The nonmetal strength member uses aramid yarn to aramid and protect the optical cable. The product will satisfy the requirements for flame resistance, heat resistance, moisture resistance, waterproof and flame retardant performance. The all-dielectric structure protects the optical fiber from electromagnetic interference and being struck by lightning.

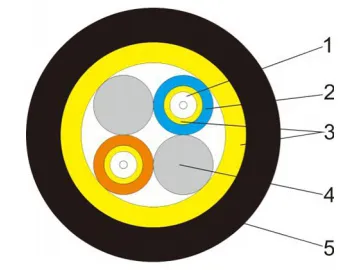

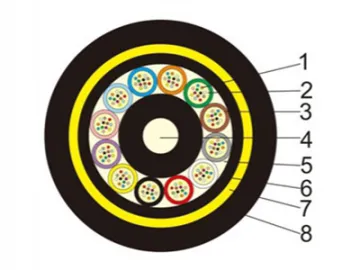

The optical fiber cable for nuclear power plants features an all-dielectric structure. This optical cable can be used in electromagnetic environment to satisfy requirements for the transmission of high speed data, and is suitable for installation in outdoor underground pipelines (with slope and drainage), indoor drive pipes and crane span structures.

The all-dielectric structure protects the optical fiber from electromagnetic interference and being struck by lightning.

Parameter| Optical cable | Unit | Technical parameter |

| Diameter of core or mode field diameter | μm | 9.2±0.4@1310nm; 10.1±@1550nm |

| Cladding diameter | μm | 125±1μm |

| Shape | circle | |

| Coaxiality of cable core and cladding layer | μm | ≤0.6 |

| Out-of-roundness of cable core | % | ≤0.6 |

| Out-of-roundness of sheath | % | ≤0.6 |

| Attenuation coefficient @1310nm | dB/km | ≤0.4 |

| Attenuation coefficient @1550nm | dB/km | ≤0.35 |

| Attenuation coefficient after the tests @1310nm | dB/km | ≤2 |

| Attenuation coefficient after the tests @1550nm | dB/km | ≤2 |

| Maximum allowed tensile force(installation) | N | 3000 |

| Maximum allowed tensile force(operation) | N | 1500 |

The outdoor stranded loose tube cable uses gel to fill itself in order to facilitate the tensile strength, moisture resistance and side pressure resistance. We use a nonmetal Fiber Reinforce Plastic (FRP) round bar at the center to strengthen the optical cable. The glass fiber yarn will protect the cable core and improve the flame retardant performance. The nonmetal strength member uses aramid yarn to aramid and protect the optical cable. The product will satisfy the requirements for flame resistance, heat resistance, moisture resistance, waterproof and flame retardant performance. The all-dielectric structure protects the optical fiber from electromagnetic interference and being struck by lightning.

Scan QR to Read

Links:https://www.globefindpro.com/products/50011.html

Links:https://www.globefindpro.com/products/50011.html

Recommended Products

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

-

Industrial Cable Manufacturer

Industrial Cable Manufacturer

Hot Products